Viscous dissipation measuring device and measuring method

A viscous dissipation and measurement device technology, applied in the field of polymer rheology testing, can solve the problem of low measurement accuracy and achieve high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

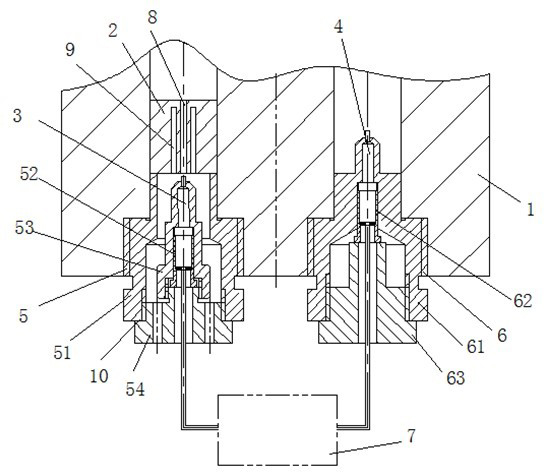

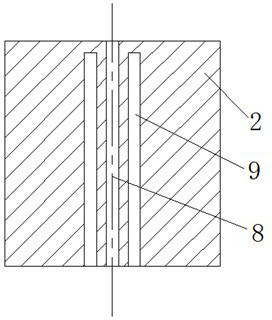

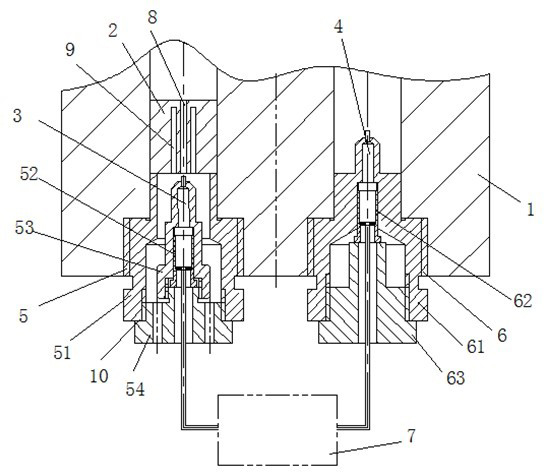

[0024] like figure 1 and figure 2 As shown, a viscous dissipation measuring device of the present invention includes a rheometer barrel, a capillary die, a temperature sensor, a temperature sensor two, a fixing device one, a fixing device two and a data acquisition system, wherein the rheometer material There are two barrels, set on the left and right, and each rheometer barrel is respectively provided with an outlet, the capillary die and temperature sensor one are fixed at the outlet on the left side through the fixing device one, and the temperature sensor two is fixed on the right side through the fixing device two At the side outlet, temperature sensor 1 and temperature sensor 2 are respectively connected to the data acquisition system through data lines. An annular groove is opened around the central hole of the capillary die, and the opening of the annular groove is set downward. The fixing device 1 includes an outer hexagonal mouth mold support 1, an open top sleeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com