Method for recovering pattern sapphire substrate

A patterned sapphire and substrate technology, which is applied in the field of optoelectronics, can solve the problems that PSS cannot be reused and the production cost is high, and achieve the effects of short recycling cycle, improved utilization rate and simple recycling method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

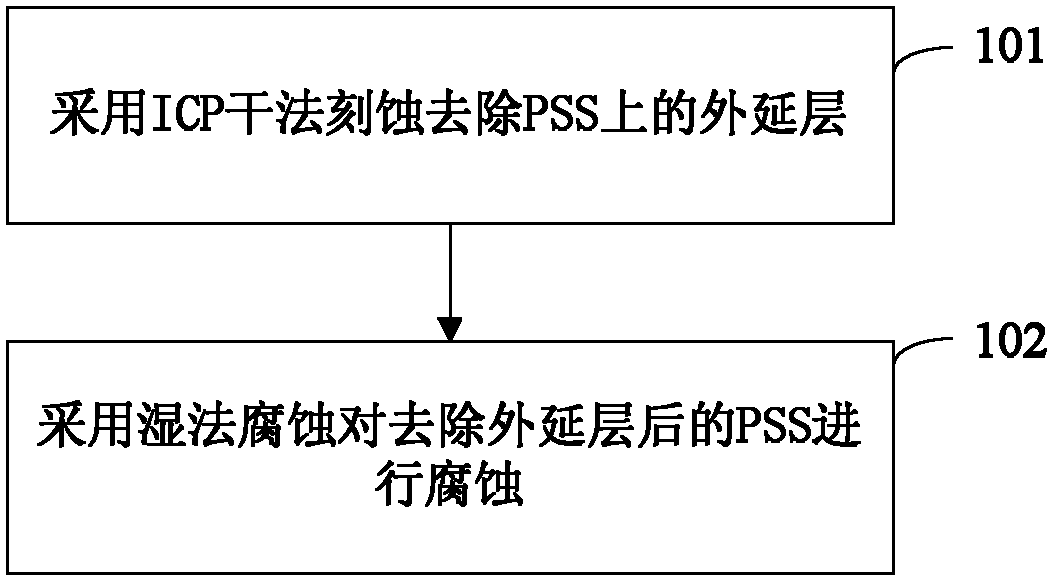

[0024] Such as figure 2 As shown, the embodiment of the present invention provides a kind of method of reclaiming PSS, and this method comprises:

[0025] Step 101: using ICP dry etching to remove the epitaxial layer on the PSS.

[0026] Dry etching is used to ensure that the epitaxial layer is completely etched, and the damage to the substrate material is small.

[0027] Step 102: Etching the PSS after removing the epitaxial layer by wet etching.

[0028] After wet etching, defects such as etching damage and dirt caused by dry etching on the PSS are removed, and a reusable PSS is obtained.

[0029] In the embodiment of the present invention, the epitaxial layer on the PSS is removed by ICP dry etching, and then the etching damage and dirt caused by dry etching are removed by wet etching, so as to obtain a reusable PSS, which greatly improves the The utilization rate of PSS is improved, thereby reducing the production cost of LED. In addition, the recycling method is simp...

Embodiment 2

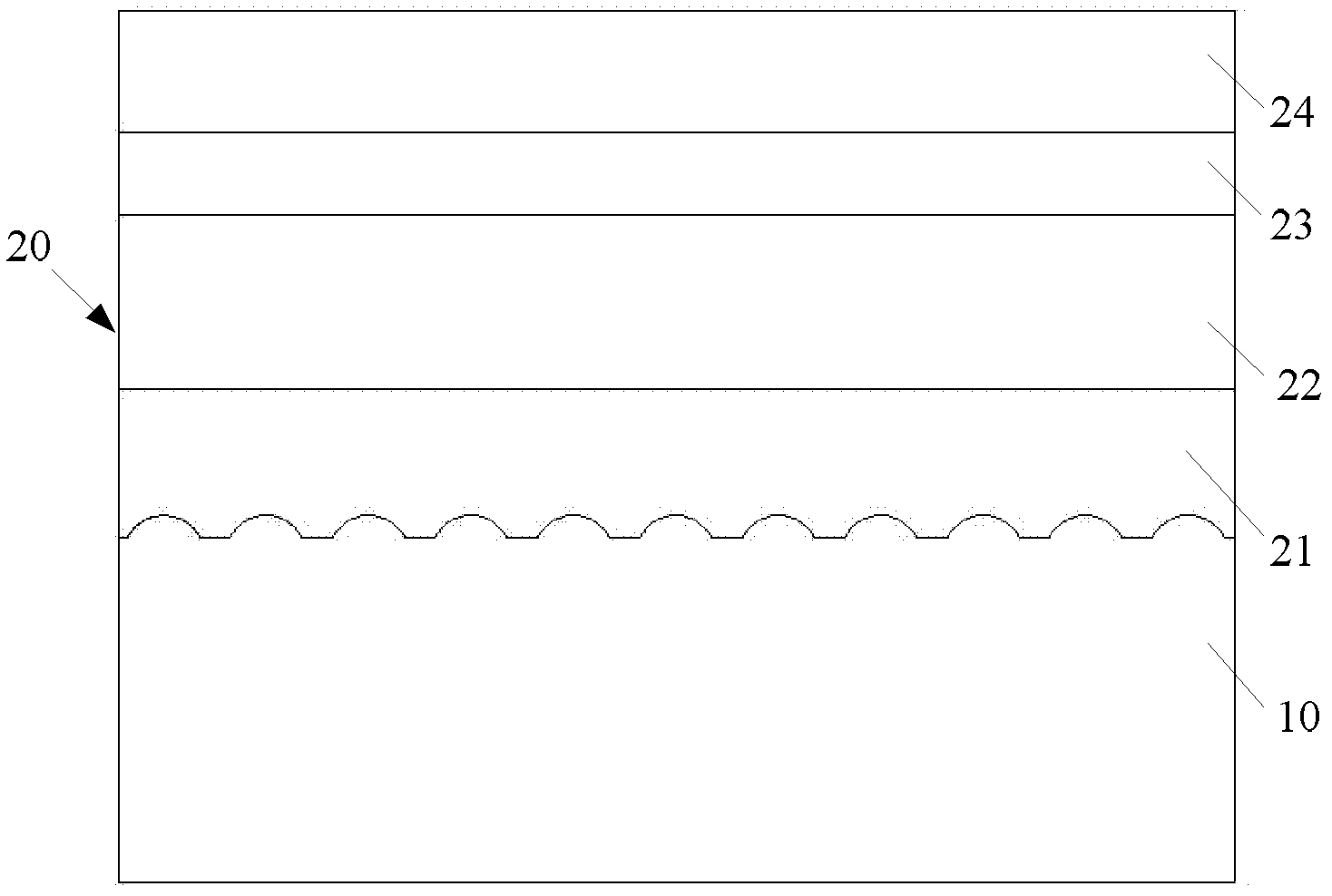

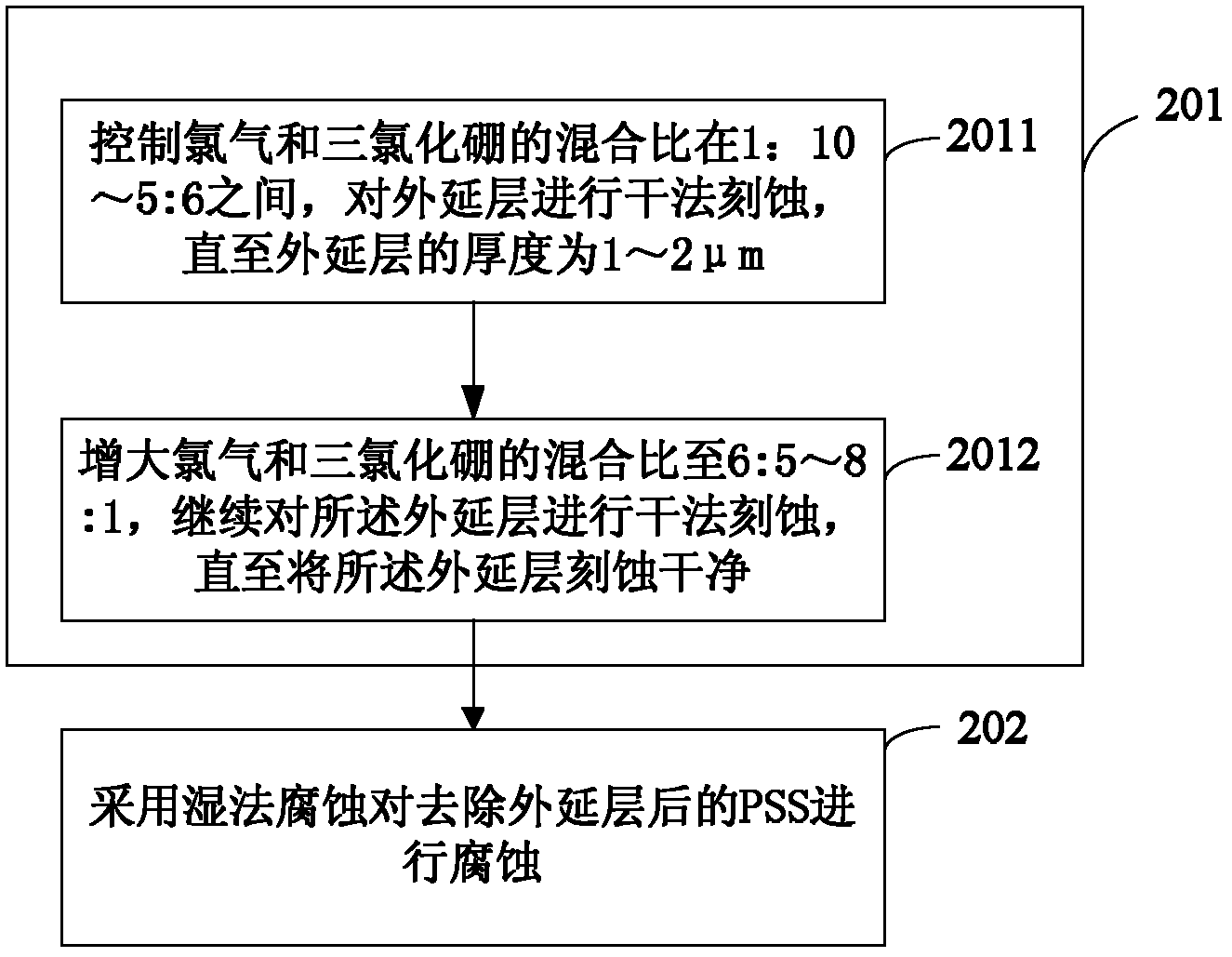

[0031] In this embodiment, taking , as an example, the embodiment of the present invention is described in detail. Such as image 3 As shown, the present embodiment provides a method for reclaiming a patterned sapphire substrate, the method comprising:

[0032] Step 201: using ICP dry etching to remove the epitaxial layer on the PSS.

[0033] Specifically, a mixed gas of chlorine gas and boron trichloride is used as the main reaction gas for ICP dry etching.

[0034] The mixed gas of chlorine gas and boron trichloride is used as the main reaction gas, which can effectively remove the epitaxial layer on the PSS without damaging the PSS material and avoiding damage to the patterned appearance of the PSS.

[0035] Preferably, this step specifically includes:

[0036] Step 2011: Control the mixing ratio of chlorine gas and boron trichloride between 1:10-5:6, and perform dry etching on the epitaxial layer until the thickness of the epitaxial layer is 1-2 μm.

[0037] Controllin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com