Method for lowering carbon monoxide content in main smoke of cigarette

A cigarette mainstream smoke and carbon monoxide technology, applied in tobacco, tobacco processing, application, etc., can solve the problems of difficult popularization and application, expensive microwave equipment, high processing cost, etc., achieve great economic significance, improve smoking safety and adaptability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

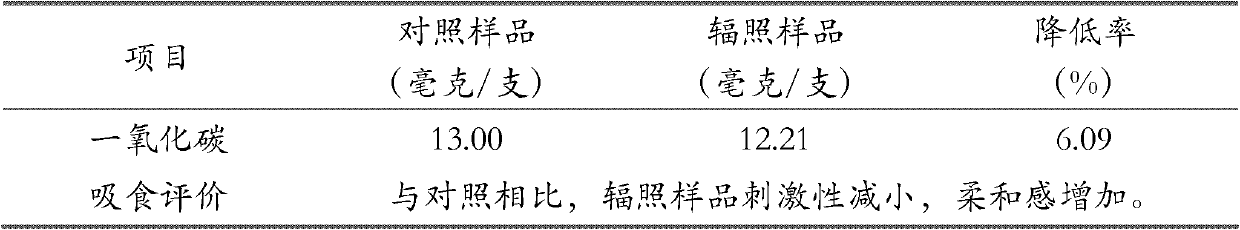

Embodiment 1

[0026] Randomly take 150kg of first-cured tobacco leaves, pack each 50kg into a box, a total of 3 boxes, and pack them in a corrugated box with a length x width x height of 70cm x 60cm x 50cm. The stacking thickness of the tobacco leaves in the carton is 26-72cm. 0.20~0.34g / cm 3 ;Place the packaged tobacco leaves on the conveying device with a conveying speed of 0.02-0.3m / s; the tobacco leaves placed on the conveying device are irradiated with electron beam / X-rays generated by an electron accelerator, and the energy of the electron accelerator is 5-10MeV , the beam current is 0.3-20mA, the beam power is 10-20kW, the maximum scanning width is 100cm, the scanning frequency is 5-15Hz, the irradiation dose is 1kGy, the way of secondary irradiation is adopted, and the tobacco leaves are transported through the conveying device twice. The scanning window of the electron accelerator is irradiated, and half of the radiation dose is received at a time. After the first irradiation, the ...

Embodiment 2

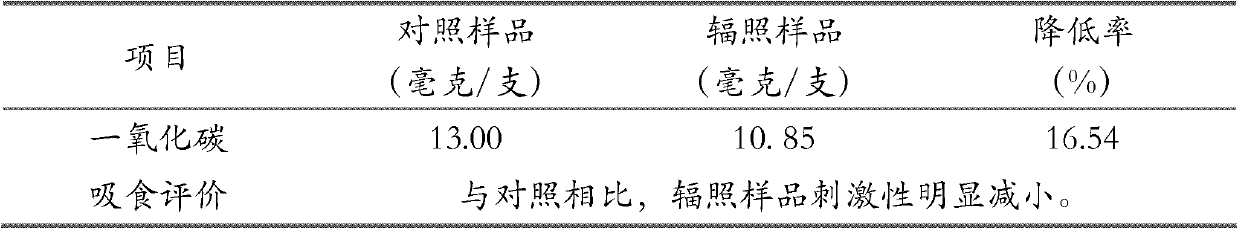

[0030] Randomly take 3 boxes of re-cured tobacco leaves packed in standard boxes, the carton length x width x height is 113.6cm x 72cm x 72.5cm, and each box weighs 200kg. Use 5kGy dose of X-rays for irradiation treatment. After irradiation, the tobacco leaves are rolled by a cigarette rolling machine, and 40 cigarettes that meet the measurement requirements are randomly selected. According to the standard conditions stipulated in GB / T 19609-2004, a smoking machine is used to simulate the state of human smoking. , using a gas absorption bottle to collect carbon monoxide in the smoke, using non-scattering infrared method to measure the content of carbon monoxide, using the corresponding unirradiated cigarette sample as a control, and evaluating smoking. The results are shown in Table 2.

[0031] Table 2 Carbon monoxide content and its change in re-cured tobacco before and after irradiation

[0032]

Embodiment 3

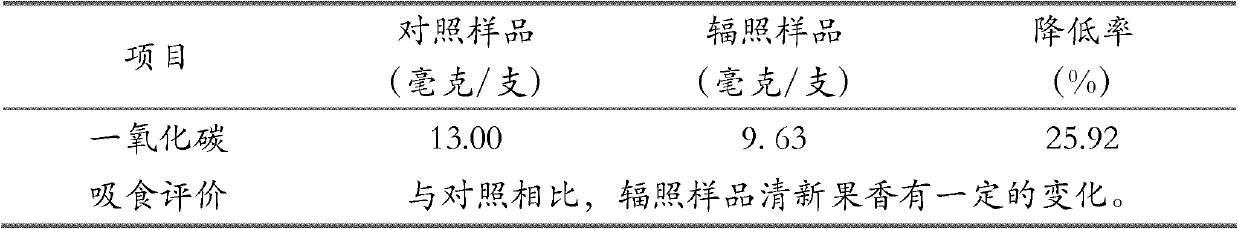

[0034]Take 3 boxes of finished cigarettes at random, the carton length x width x height is 47.5cm x 26cm x 59.5cm, each box weighs 15kg, and the quantity is 50. The electron beam with a dose of 10kGy is used for irradiation treatment. After irradiation, 40 cigarettes that meet the measurement requirements are randomly selected. According to the standard conditions stipulated in GB / T 19609-2004, a smoking machine is used to simulate the state of human smoking, and a gas absorption bottle is used to collect cigarettes. The carbon monoxide in the air was measured by non-scattering infrared method, and the corresponding unirradiated cigarette samples were used as the control, and the smoking evaluation was carried out. The results are shown in Table 3.

[0035] Table 3 Carbon monoxide content and its changes in finished cigarettes before and after irradiation

[0036]

[0037] It can be seen from Tables 1 to 3 that the method for reducing the carbon monoxide content in the mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com