Mixed ether ethanol gasoline

An ethanol gasoline and mixed ether technology, which is applied in the field of automotive gasoline, can solve the problems of difficulty in transportation, storage and use, difficult control of oil product quality, and high emission of harmful gases, and achieves efficient prevention of efficient catalytic nitrogen reduction and efficient prevention of nitrogen. The effect of simultaneous reduction of oxidation and pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

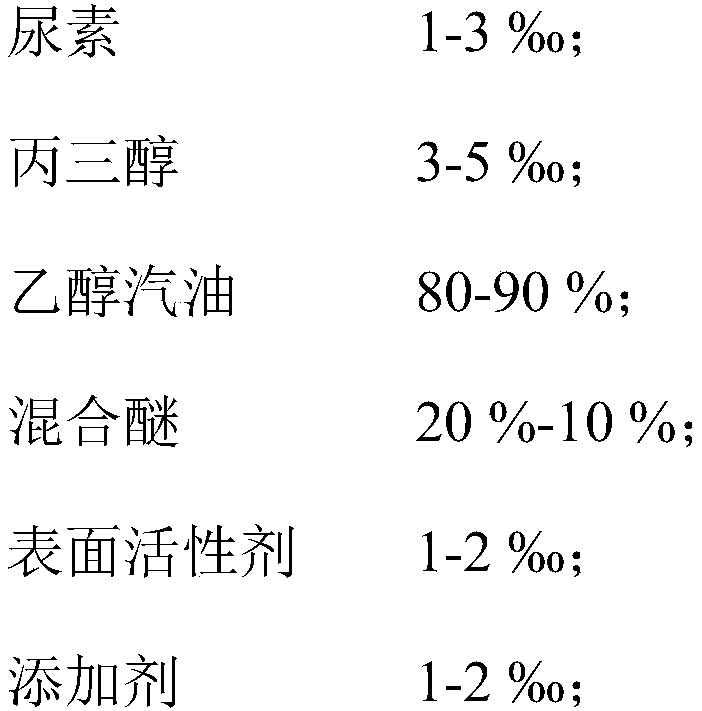

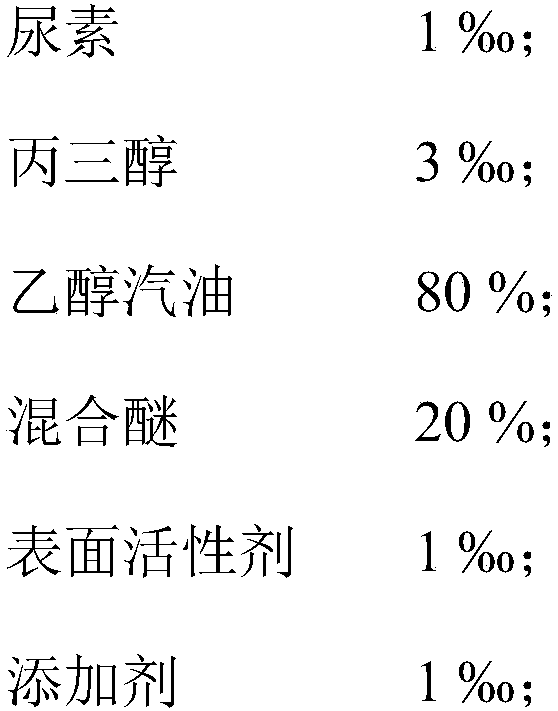

[0030] A mixed ether ethanol gasoline is composed of the following components by weight percentage:

[0031]

[0032] Wherein the mixed ether is composed of dimethoxy dimethyl ether and trimethoxy dimethyl ether according to a weight ratio of 10:1; the percentage by weight of ethanol in ethanol gasoline is 10% (gasoline accounts for 90%); the surfactant is alkane The base phenol ether surfactant, the additive is a carbon deposition slow solvent and a swelling inhibitor in a weight ratio of 1:1, the gasoline is commercially available No. 92 national standard gasoline, and the above components are stirred and mixed to obtain ethanol gasoline.

Embodiment 2

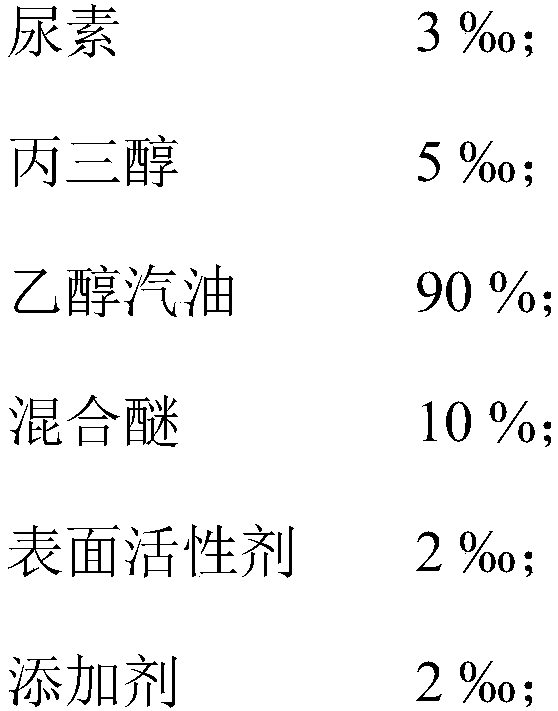

[0034] A mixed ether ethanol gasoline is composed of the following components by weight percentage:

[0035]

[0036] Wherein the mixed ether is composed of dimethoxy dimethyl ether and trimethoxy dimethyl ether according to a weight ratio of 5:1; the percentage by weight of ethanol in ethanol gasoline is 20% (gasoline accounts for 80%); the surfactant is ten Dialkylphenol ether sulfonate, the additive is a carbon deposition slow solvent and a swelling inhibitor in a weight ratio of 1:2, the gasoline is commercially available No. 95 national standard gasoline, and the above components are stirred and mixed to obtain ethanol gasoline.

Embodiment 3

[0038] A mixed ether ethanol gasoline is composed of the following components by weight percentage:

[0039]

[0040] Wherein the mixed ether is composed of dimethoxy dimethyl ether and trimethoxy dimethyl ether according to the weight ratio of 8:1; the percentage by weight of ethanol in ethanol gasoline is 12% (gasoline accounts for 88%); the surfactant is ten Dialkyl alcohol ether sulfonate, the additive is a carbon deposition slow solvent and a swelling inhibitor in a weight ratio of 1:2, the gasoline is commercially available No. 95 national standard gasoline, and the above components are stirred and mixed to obtain ethanol gasoline.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com