Internal combustion engine with exhaust device

A technology for exhaust equipment and internal combustion engines, applied to internal combustion piston engines, exhaust treatment, mechanical equipment, etc., can solve problems such as shortened service life of components, damage to catalytic converters, damage to gasoline particulate filters, etc., to reduce emissions and reduce efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

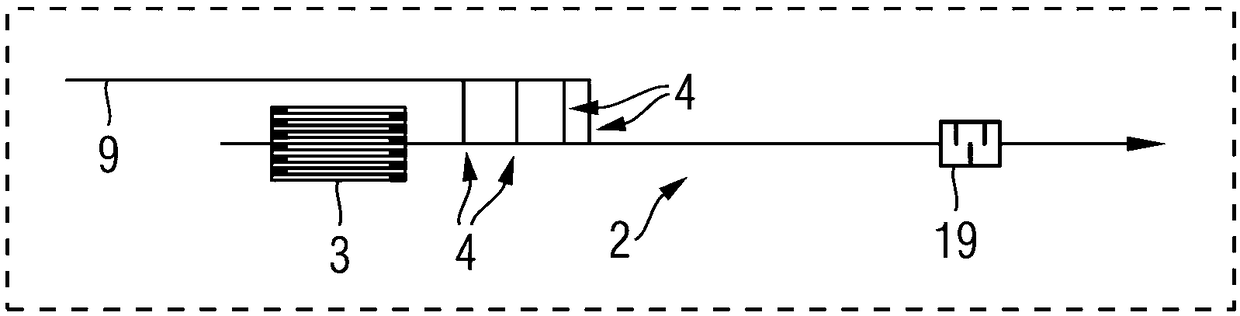

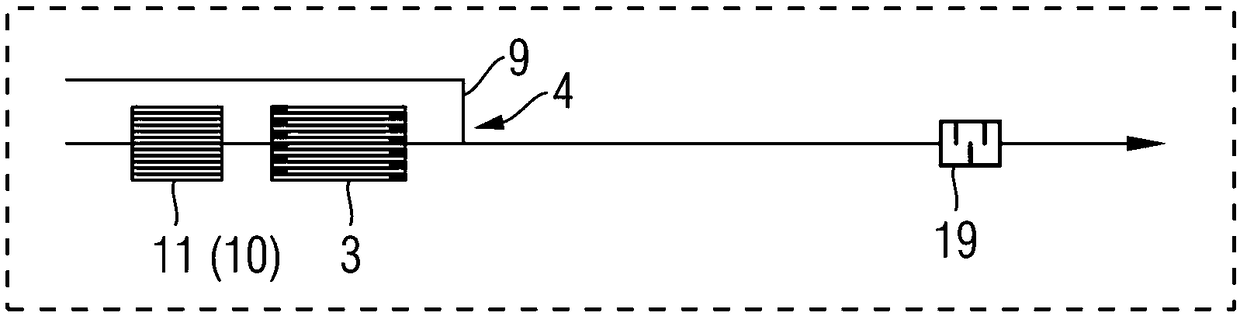

[0027] then in Figures 1 to 13 In , the same reference numerals are applied to the same components.

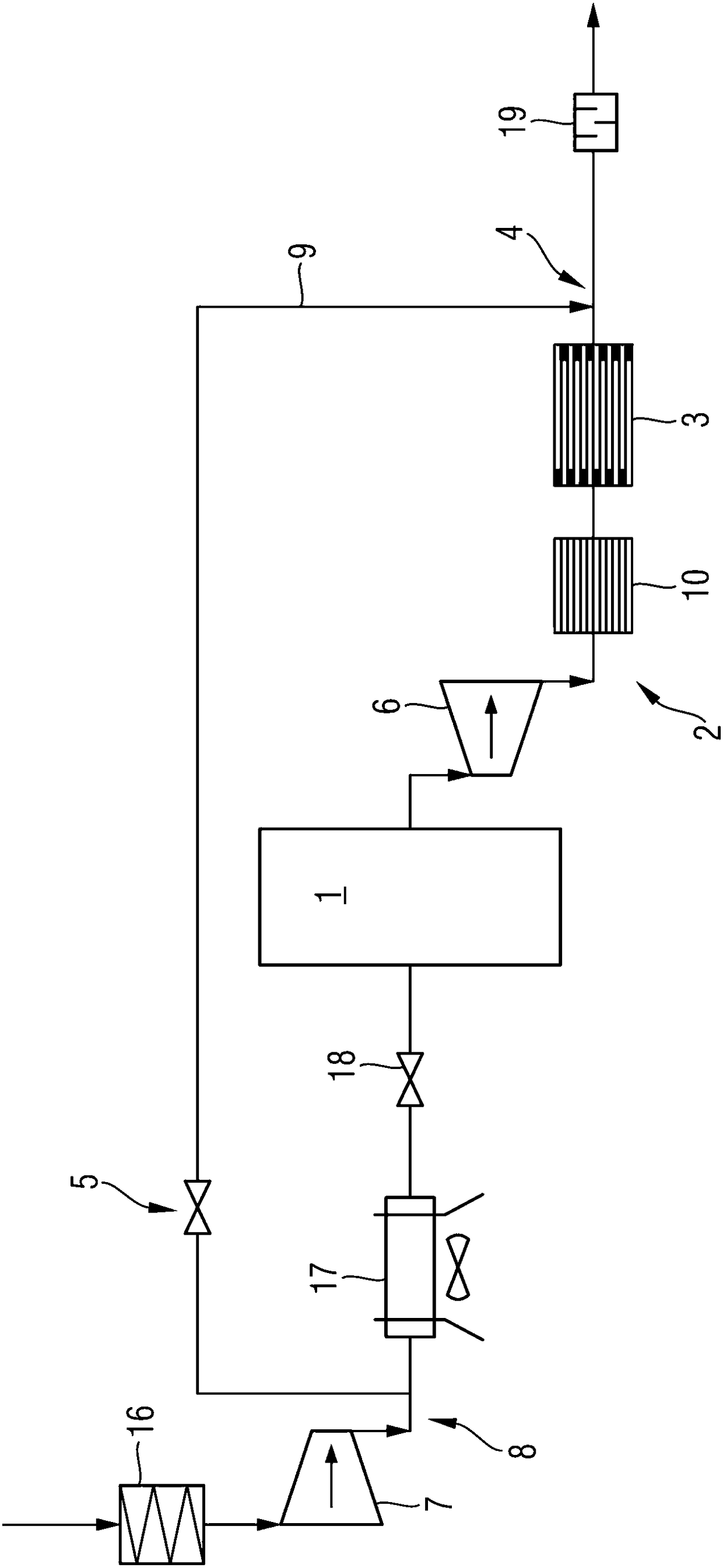

[0028] figure 1 A schematic design of an internal combustion engine 1 with an exhaust gas system 2 according to the invention is shown. The exhaust system 2 serves to discharge the exhaust gas of the internal combustion engine 1 , wherein a particle filter 3 is arranged in the exhaust system 2 . Furthermore, a secondary air inlet 4 is provided in the exhaust device 2 , which introduces secondary air into the exhaust device 2 via a closing element 5 . The closure element 5 can be, for example, a valve or a damper. According to the invention, the secondary air inlet 4 is arranged downstream of the particle filter 3 in the flow direction of the exhaust gas in the exhaust system 2 .

[0029] The flow direction of the exhaust gas is not indicated by arrows in the exhaust system 2 . The flow direction of the secondary air is likewise not indicated by arrows in the region of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com