Ceramic mushroom-shaped teapot filter and teapot with same

A filter head and teapot technology, which is applied to clay products, beverage preparation devices, other household appliances, etc., can solve the problems of easy clogging of the filter screen and unsmooth pouring of water, and achieve the effects of multiple filtration directions, less clogging and large filtration area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, the present invention will be further explained with examples in conjunction with the drawings. The dimensions and specific shapes involved are only for illustration, and the scope of the present invention is not limited to these dimensions and shapes.

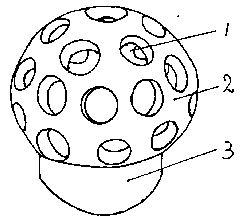

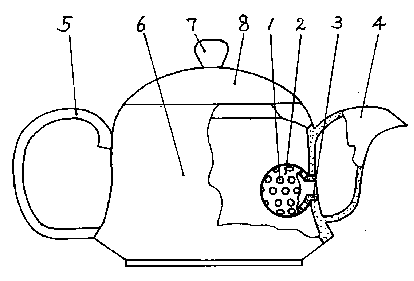

[0025] Such as Figure 1-2 As shown, the filter ball 2 and the pin 3 are made of purple sand pottery mud and corresponding molds. After the combination, the mud at the joint is dug out to make the two completely connected, thus forming a mushroom-shaped combination. Dig out the filter holes 1 evenly on the spherical surface. The filter hole can also be dug out first, and then combined with the pin. For example, a filter ball similar to a round sphere, dig the first hole with the top of the ball as the center, then three circles of holes, each circle digs 6 holes, the second circle digs 10, and the third circle reaches the equator. 12 holes. The thickness of the ball skin and the pin depends on the size of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com