Anti-crushing device of resin filter

A resin filter and anti-shattering technology, which is applied in the direction of ion exchange mediation/control, ion exchange water/sewage treatment, etc., can solve the problems of deteriorating water quality, crushing, and increased resistance of equipment, etc., to prolong the circulation path and reaction time , The regeneration reaction is uniform and thorough, and the effect of increasing the flow area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

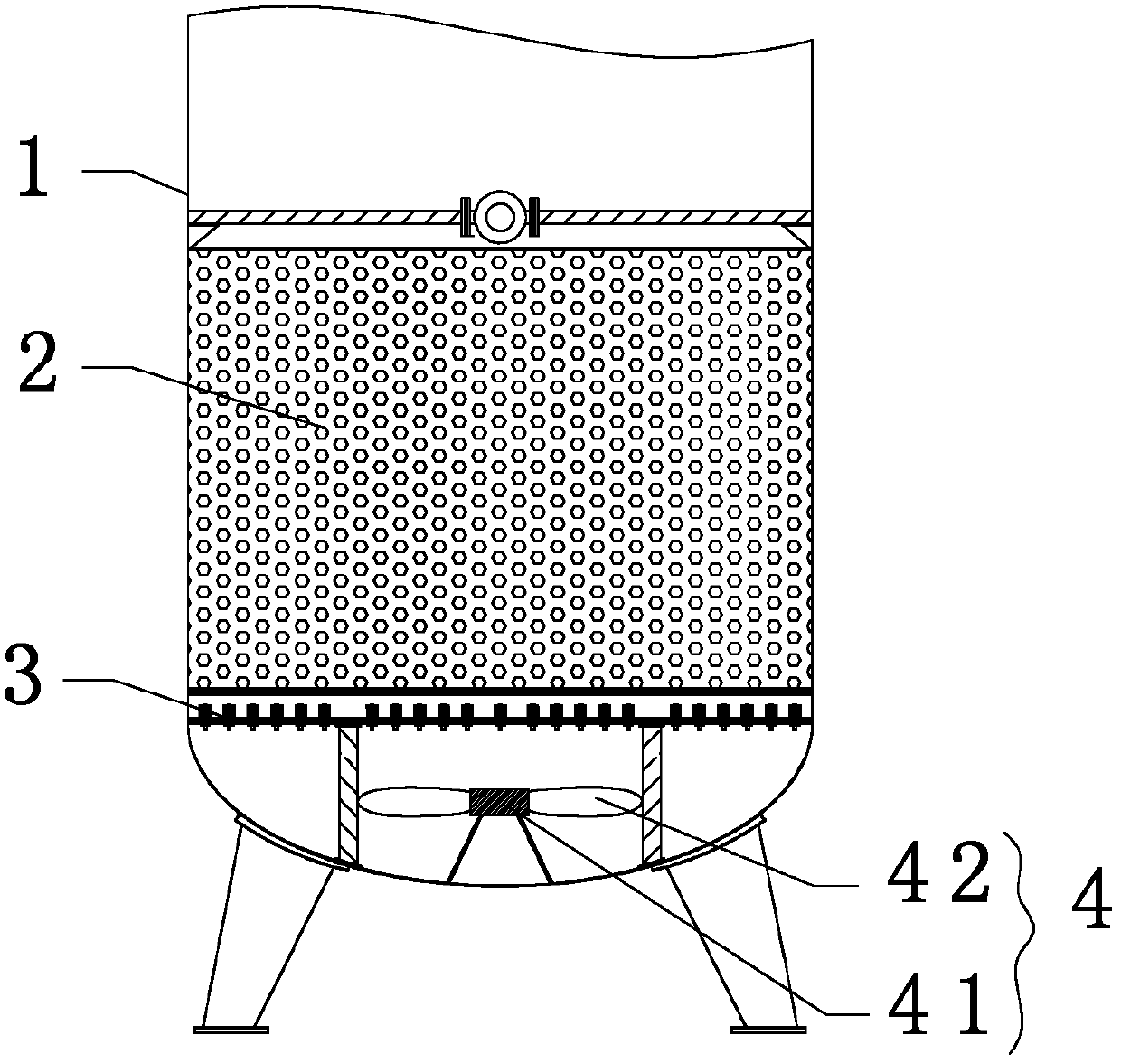

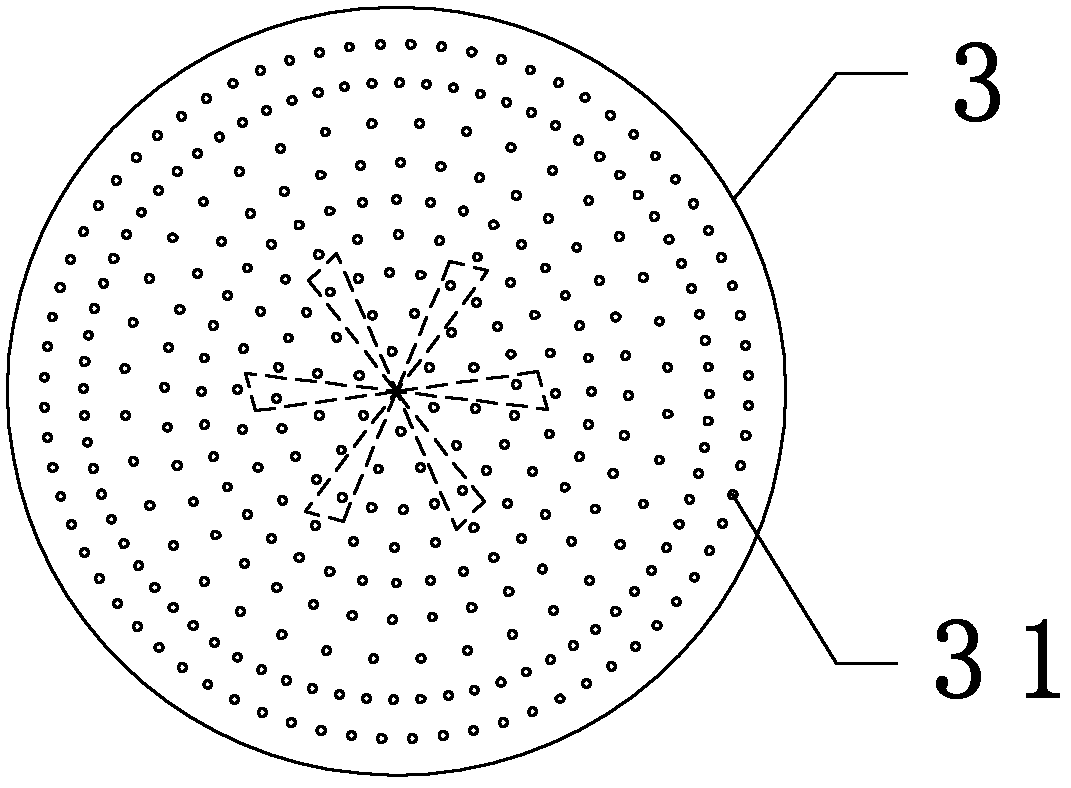

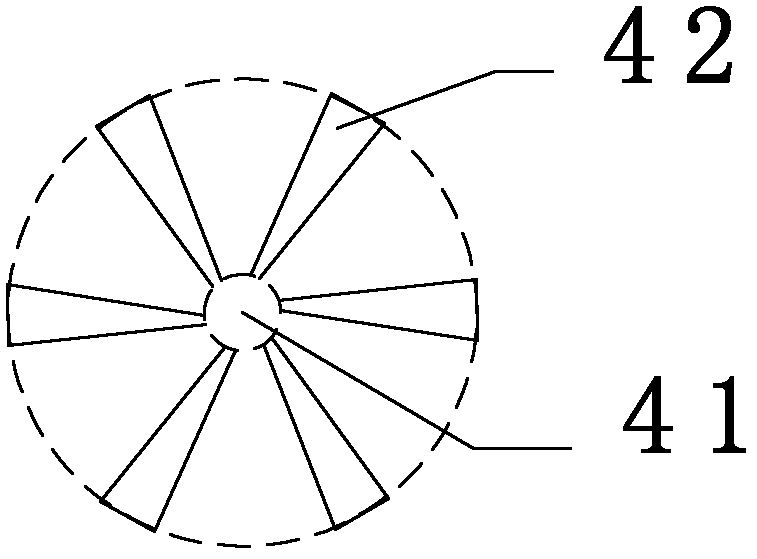

[0015] Such as figure 1 , figure 2 and image 3 The schematic structural view of an embodiment of the present invention is shown, comprising a water distribution screw 4 and a water distribution tray 3 arranged between the water distribution screw and the resin filler layer 2, the water distribution screw is fixed on the resin filter 1 inner wall, and the water distribution The plate is set between the water distribution propeller and the resin packing layer and welded on the inner wall of the resin filter. The water distribution plate is provided with a water distribution hole 31, and the water flowing up through the swirling flow behind the water distribution propeller is at the water distribution plate. The blockage causes the cross-sectional area of the water flow to increase and the flow velocity to slow down. In the present invention, the water distribution plate is circular, and the water distribution holes are radially distributed on multiple concentric circles alo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com