Separation, recovery and comprehensive utilization of waste oil from kitchen waste

A technology for separation and recycling of kitchen waste, applied in recycling technology, recovery of fatty substances, recovery of fat/fatty acids from waste, etc. It can solve the problems of unutilizable grease, grease pollution, and high grease content, and achieve high grease recovery rate. , easy to operate, low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

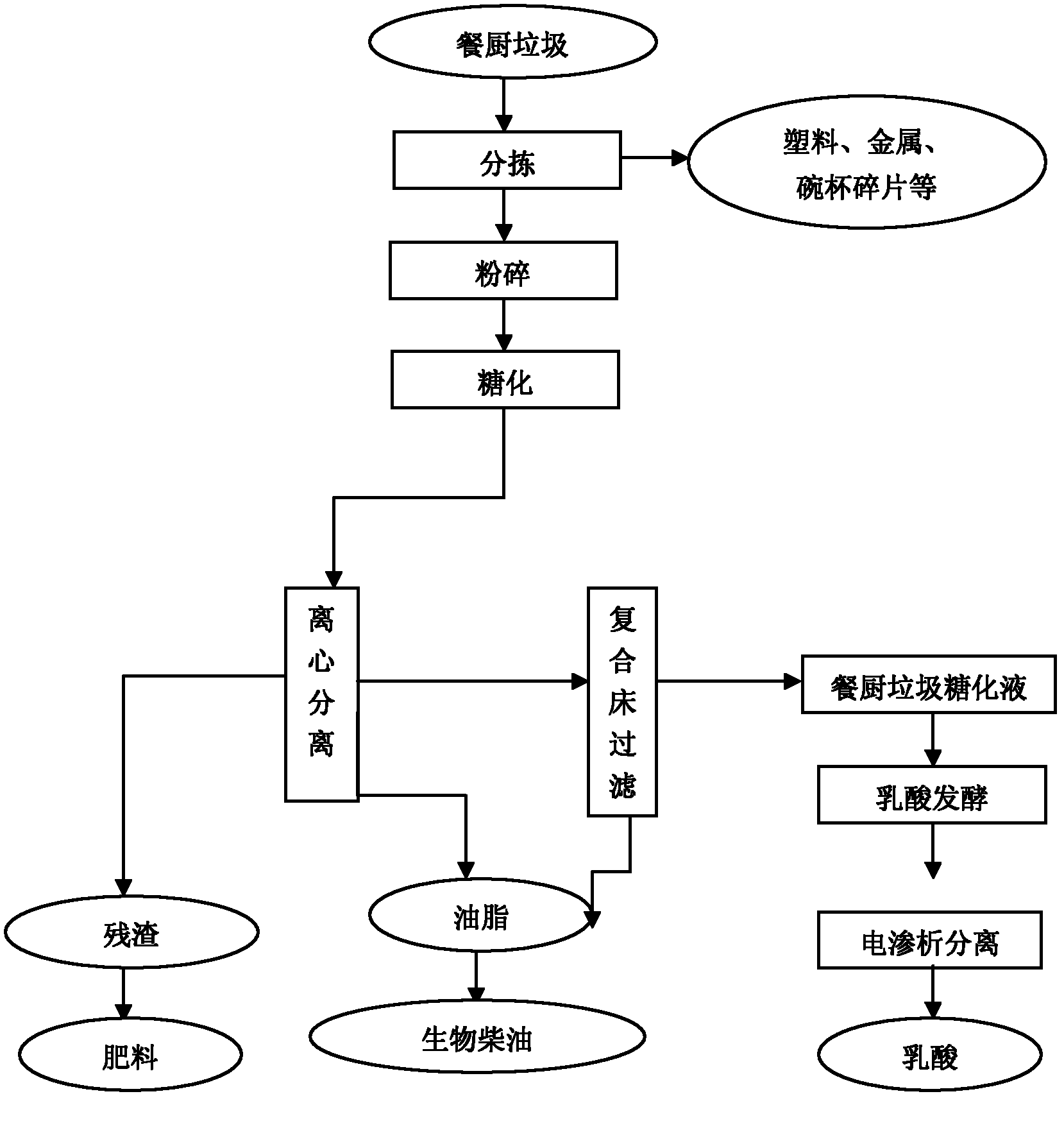

[0025] The present invention provides a process for separation, recovery and comprehensive utilization of waste oil from kitchen waste. The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0026] In this embodiment, the specific steps for the separation and recycling of grease from food waste and the comprehensive utilization of food waste resources are as follows:

[0027] (a) First, manually sort the food waste collected from canteens, restaurants, and households, and sort out the plastic, metal, bowl fragments, big bone sticks and other sundries. The remaining food waste includes residues , The residual liquid is kept for use after disinfection and sterilization;

[0028] (b) Use a multi-functional grinder to grind the sorted food waste. If there is food waste with a diameter greater than 3cm, use a knife to cut it as small as possible before crushing so that it can enter the grinder machine;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com