Fibre-reinforced compound material core and preparation method thereof

A composite material core and fiber-reinforced technology, applied in chemical instruments and methods, layered products, glass/slag layered products, etc., can solve the problems of carbon fiber composite material core brittleness, aluminum strand breakage, power transmission interruption, etc. Achieve the effects of enhanced toughness, avoiding fracture, improving safety performance and lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

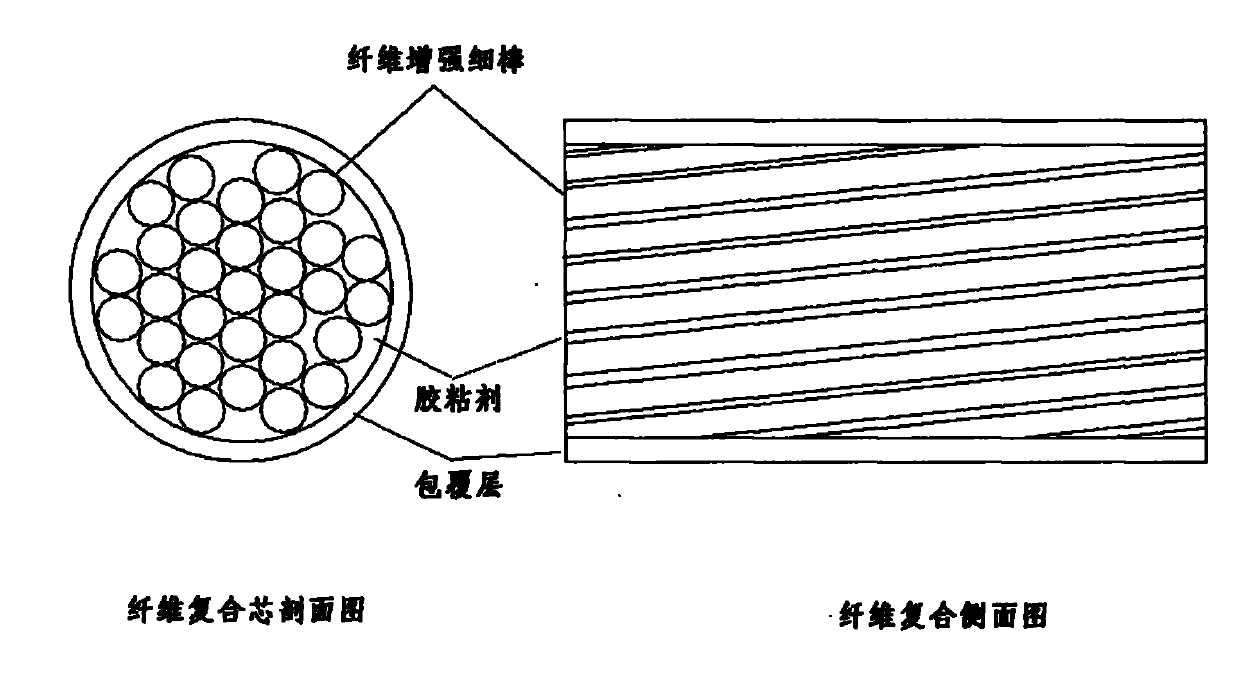

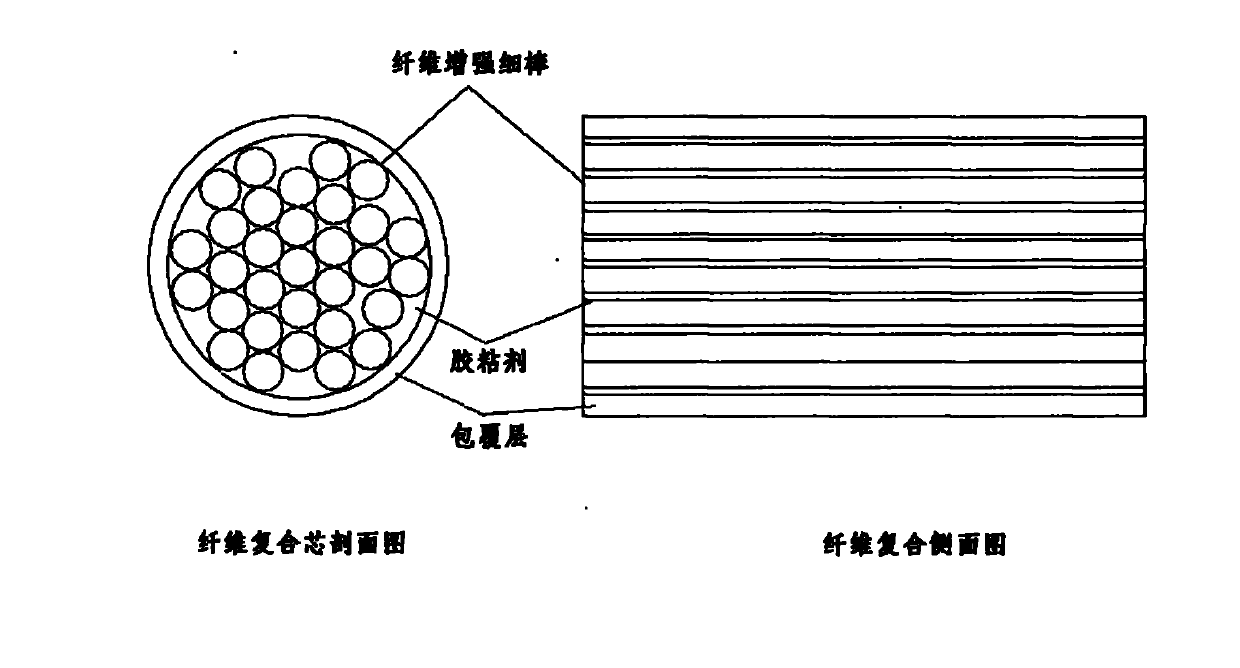

[0026] Example 1: Combining Figure 1-Figure 4 , a fiber-reinforced composite material core of the present invention, which is composed of an inner structure and an outer insulating structure, the inner structure is formed by bonding 3 to 40 parallel or helically twisted fiber-reinforced high-temperature-resistant resin-based thin rods, and the outer The layer insulation structure is a high temperature resistant non-conductive resin coating or a high temperature resistant non-conductive fiber reinforced resin layer, the thickness of which is 10-40% of the diameter of the wire core, and the thickness is uniform along the perimeter.

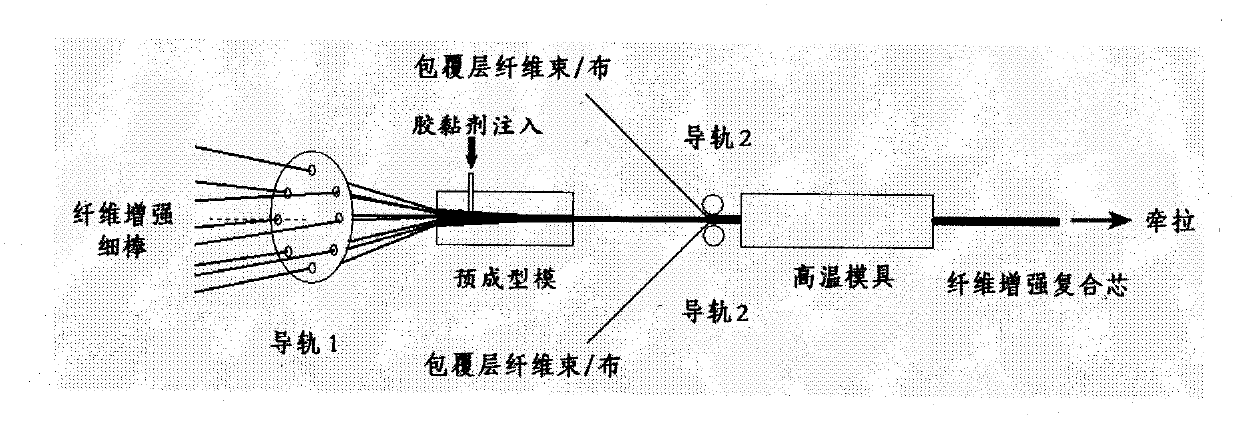

[0027] The preparation method of the fiber reinforced composite material core of the present invention, the steps are as follows:

[0028] Step 1: Preparation of fiber-reinforced high-temperature-resistant resin-based thin rods:

[0029] Fiber-reinforced high-temperature-resistant resin-based thin rods are prepared by pultrusion of continuous fibe...

Embodiment 2

[0041] Embodiment 2: the preparation method of fiber-reinforced composite material core: the steps are as follows:

[0042] Step 1: Preparation of fiber-reinforced high-temperature-resistant resin-based thin rods:

[0043] Fiber-reinforced high-temperature-resistant resin-based thin rods are prepared by pultrusion of continuous fiber bundles and high-temperature-resistant resins:

[0044] (1) Select 12k-T700 continuous carbon fiber bundles from Toray Corporation of Japan or Kevlar-3000D aramid fiber bundles from DuPont Corporation of the United States or 2400D ultra-high molecular weight polyethylene fiber bundles from Beijing Witton International Trade Co., Ltd. as continuous fiber bundles. Epoxy resin or vinyl polyester with a glass transition temperature between 100 and 250°C is used as a high temperature resistant resin;

[0045] (2) Pultruding by pultrusion machine: the pultrusion machine includes a creel, an impregnation tank, a circular high-temperature die, a post-cur...

Embodiment 3

[0055] Example 3: Preparation method of fiber-reinforced composite material: First, a carbon fiber-reinforced thin rod with a diameter of 1mm was prepared by pultrusion process, wherein the carbon fiber was Toray T700, and the resin was high-temperature-resistant epoxy resin (glass transition temperature was 210° C.), and prepared The carbon fiber reinforced thin rod has a fiber volume content of 69%. Pass 25 bundles of fine carbon fiber reinforced thin rods through figure 2 The carbon fiber composite core is prepared by the process shown: control the ratio of the speed of the rotating guide rail to the pulling speed, and determine the winding angle of the carbon fiber thin rod along the pulling direction to be 10 degrees; before the carbon fiber reinforced thin rod enters the rotating guide rail, first pass through the adhesive tank, After passing through the fixed guide rail, the excess adhesive and air bubbles are squeezed out; the continuous glass fiber bundle (continuous...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com