Special supporting and lifting type rail trailer for waste and scrap automobiles

A lifting type, automobile technology, applied in the direction of motor vehicles, recycling technology, vehicle scrapping and recycling, etc., can solve the problems that ordinary flat cars cannot meet the loading requirements of different types of vehicles, affect the normal operation of production, and have a small range of applicable models, etc., to achieve Save design materials and costs, simple and reliable operation, low vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

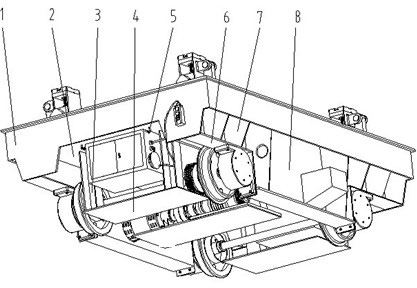

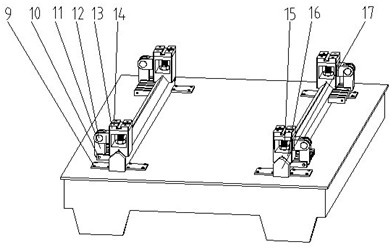

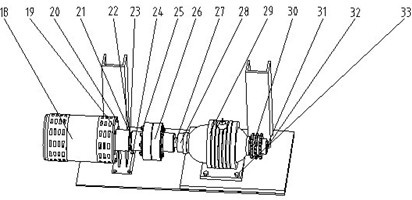

[0023] Lifting and lifting rail flat car for scrap cars, including frame assembly, wheel assembly, battery box 47, drive system, transmission system, braking system, lifting and lowering system and circuit control system, the lifting The lifting system is fixedly connected to the upper cover plate 1 of the vehicle frame assembly; the battery box 47 and the circuit control system are respectively fixed by lifting lugs 5 welded to the rear end and front end of the partition plate 2 in the middle of the vehicle frame assembly; The drive system and the transmission system are fixed on the middle bottom plate 4 of the vehicle frame assembly; the brake system is fixedly connected to the drive wheel bearing seat 43 of the drive system, and the lift system includes guide rail fastening bolts 9. Limiting block positioning bolt 10, limiting block 11, pin shaft 12, lifting tray 13, lifting tray connecting bolt 14, tray inner hexagonal fastening bolt 15, slider 16 and sliding guide rail 17...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com