Double spiral disc butterfly aircraft

A helical disk and double-helix technology, applied in the field of aircraft, can solve the problems of high cost, heavy weight of aircraft, complex structure of aircraft, etc., and achieve the effect of light weight and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples, but the examples do not constitute any limitation to the present invention.

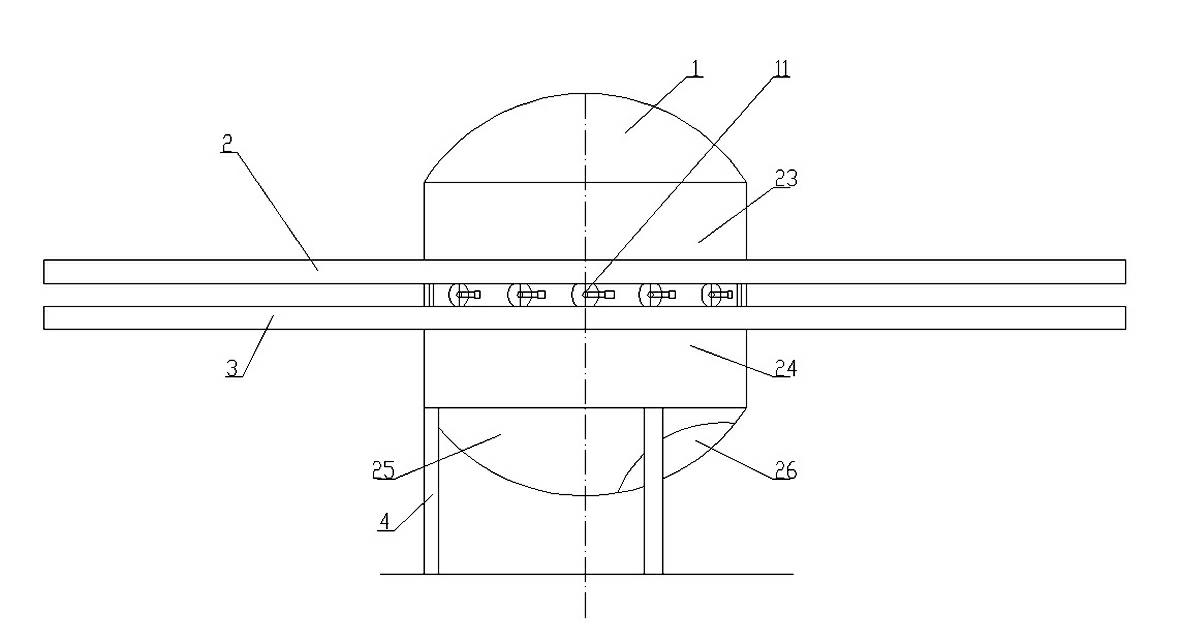

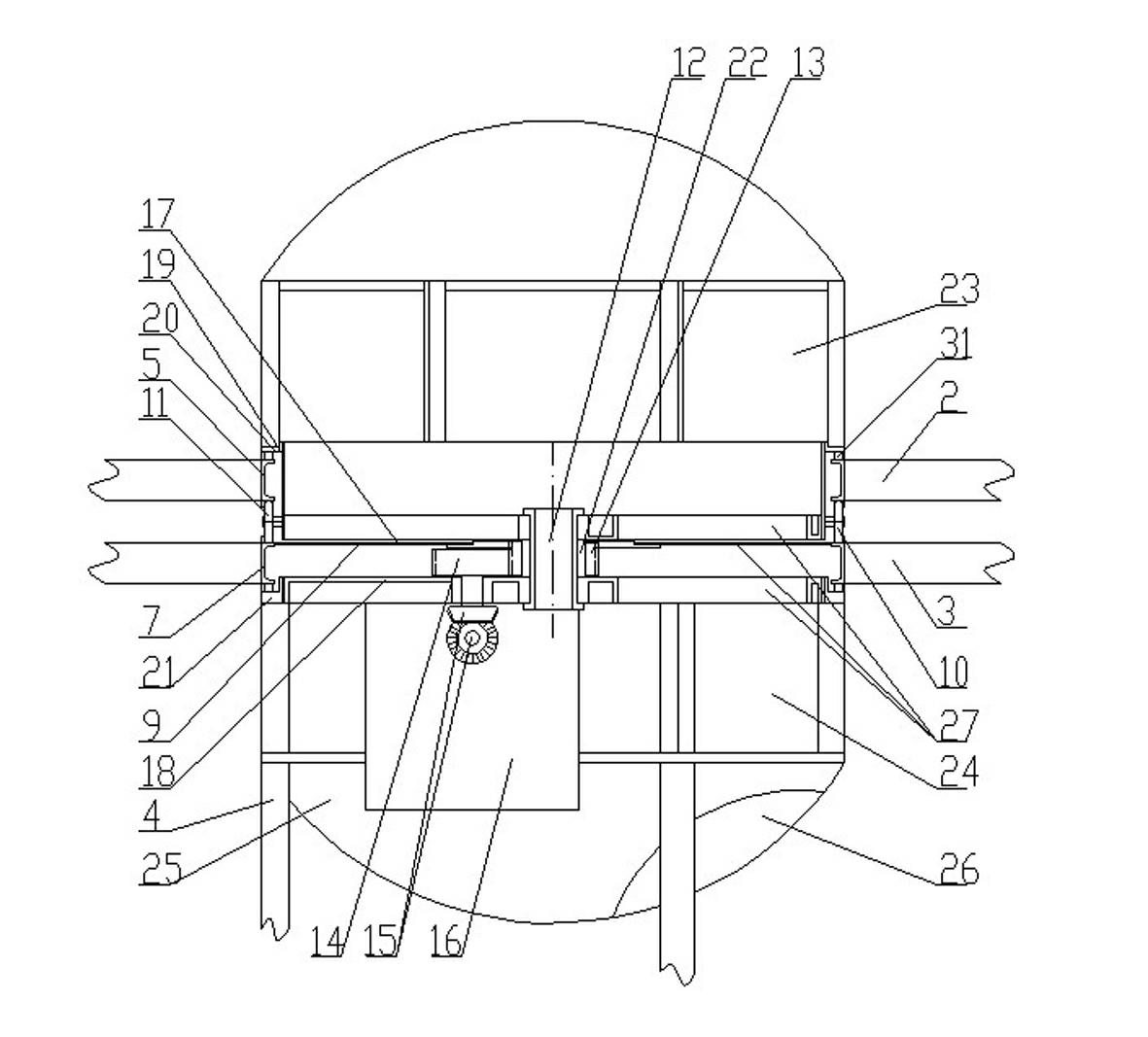

[0030] The structure of the double-helix disc-shaped aircraft is as follows: figure 1 Shown, comprise engine 16, upper fuselage 23, lower fuselage 24, upper spiral disk 2 and lower spiral disk 3, upper fuselage 23 is provided with glass top cover 1, and lower fuselage 24 is provided with bottom cover 25 and Leg 4, hatch cover 26 is arranged on the bottom cover 25, and upper spiral disk 2 and lower spiral disk 3 are installed between upper fuselage 23 and lower fuselage 24.

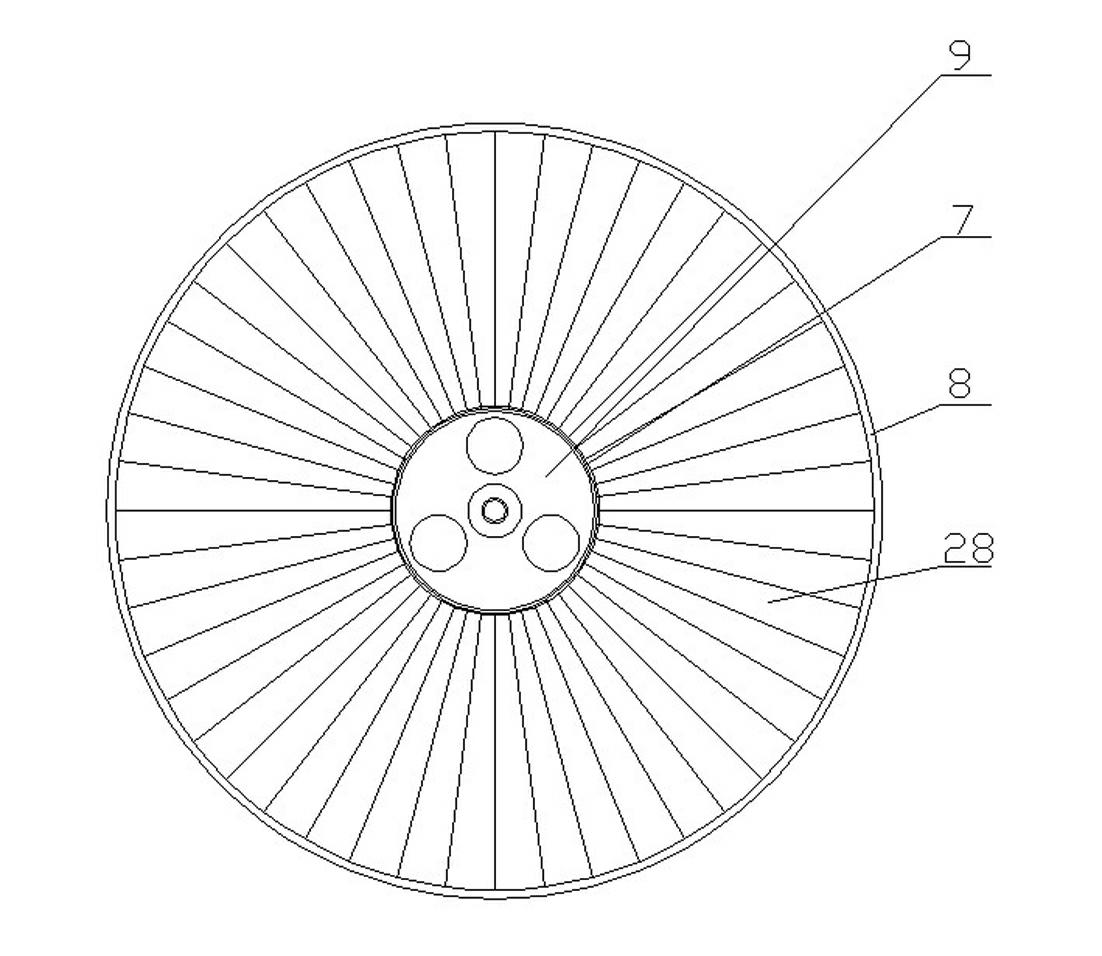

[0031] The structure of its fuselage is as follows figure 2 As shown, it is divided into upper and lower parts. The bottom of the upper fuselage 23 is provided with Figure 4 Shown loam cake 17, the top of lower fuselage 24 is provided with Figure 5 The shown lower cover 18, the upper cover 17 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com