Working method and structure of packaging bag double-outlet nozzle adding device

A technology of packaging bags and actuators, which is applied in the direction of packaging, etc., can solve the problems that it cannot be used as a component device of a horizontal automatic packaging machine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

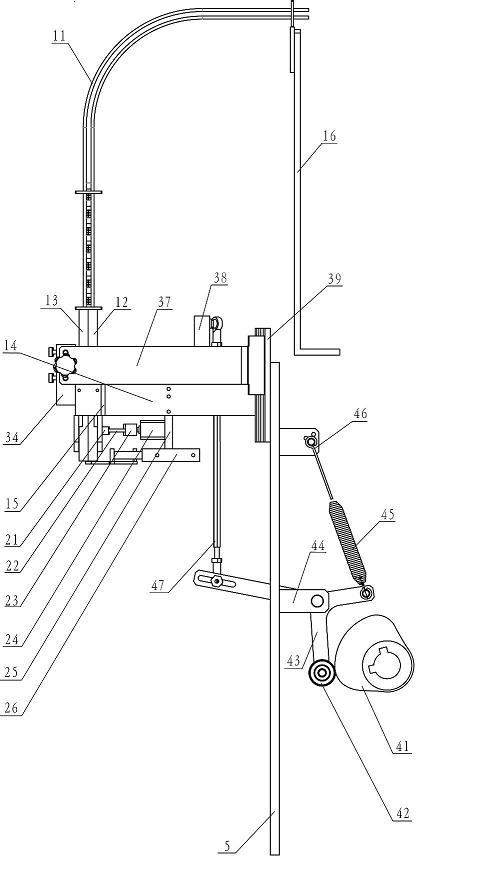

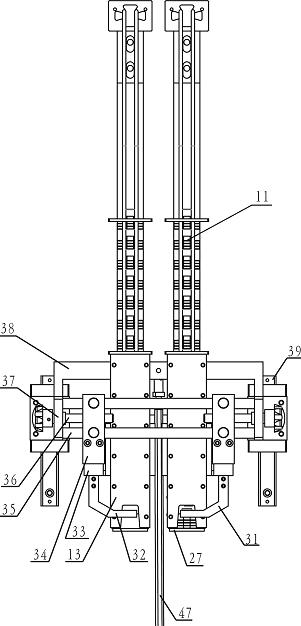

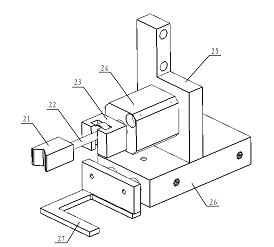

[0030] Attached below Figure 1-4 , the present invention will be described in further detail. The present invention is a working method and structure of a packaging bag double-out spouting device, and its structure includes: a nozzle slideway mechanism 1, a mouth blocking mechanism 2, a nozzle adding actuator 3, a nozzle adding cam driving mechanism 4, and a mounting substrate 5 . The nozzle slideway mechanism 1 and the mouth stop mechanism 2 have two in each set of double-out nozzle adding devices, the nozzle slideway mechanism 1, the nip mechanism 2, the nozzle adding actuator 3 and the nozzle adding cam driving mechanism 4 is located on both sides of the installation substrate 5, and the installation substrate 5 can be fixedly connected with the horizontal automatic packaging machine.

[0031] Described suction nozzle slideway mechanism 1 is made up of suction nozzle slide rail 11, solid slideway 12, transparent slideway 13, slideway support 14, guide rail support 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com