Automatic righting and feather conveying device of badminton feather slices

A technology of automatic turning and badminton, which is applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems that automatic straightening and hair feeding cannot be used, so as to improve production efficiency and production cost, save labor costs, and reduce manual intervention Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

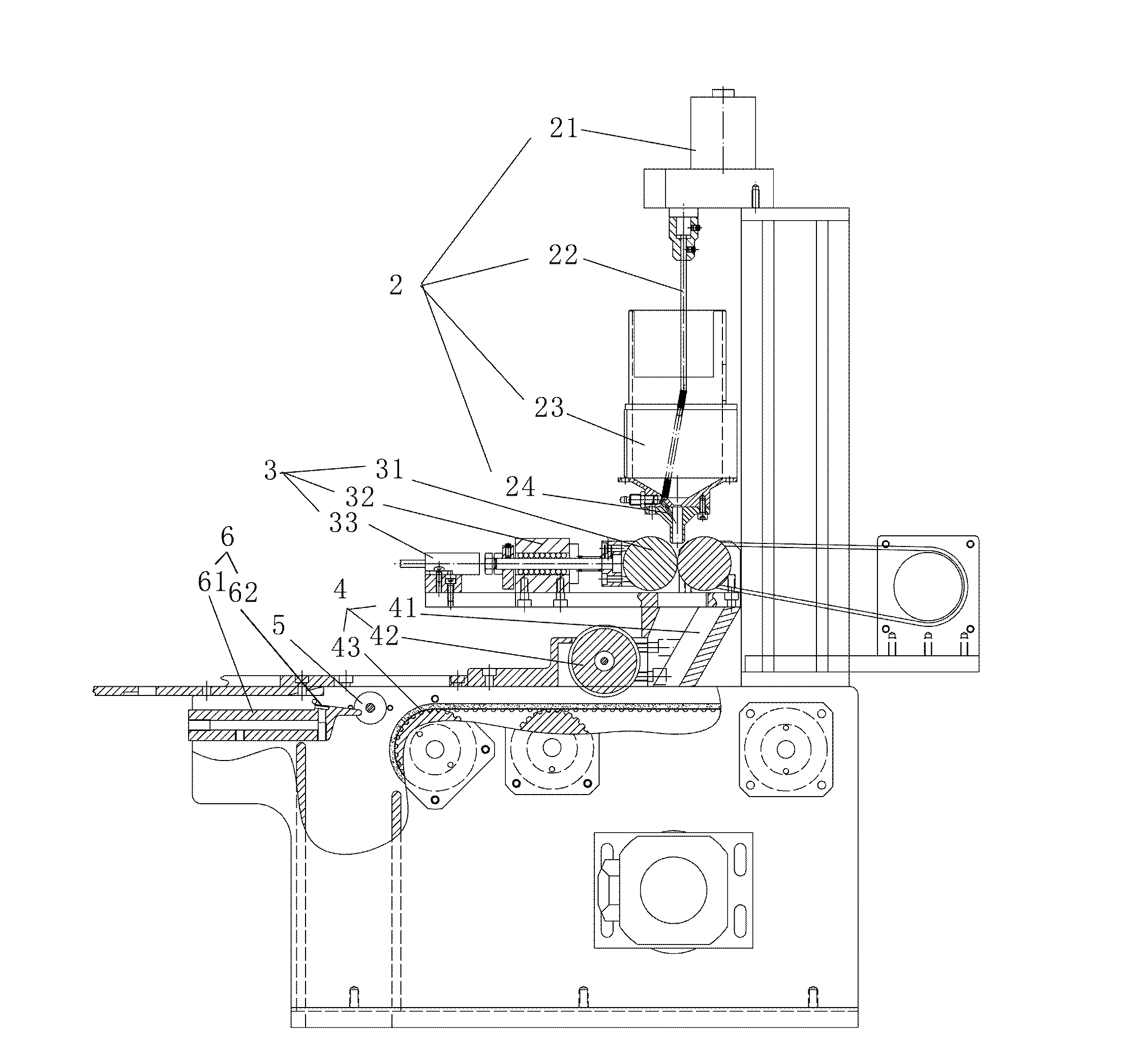

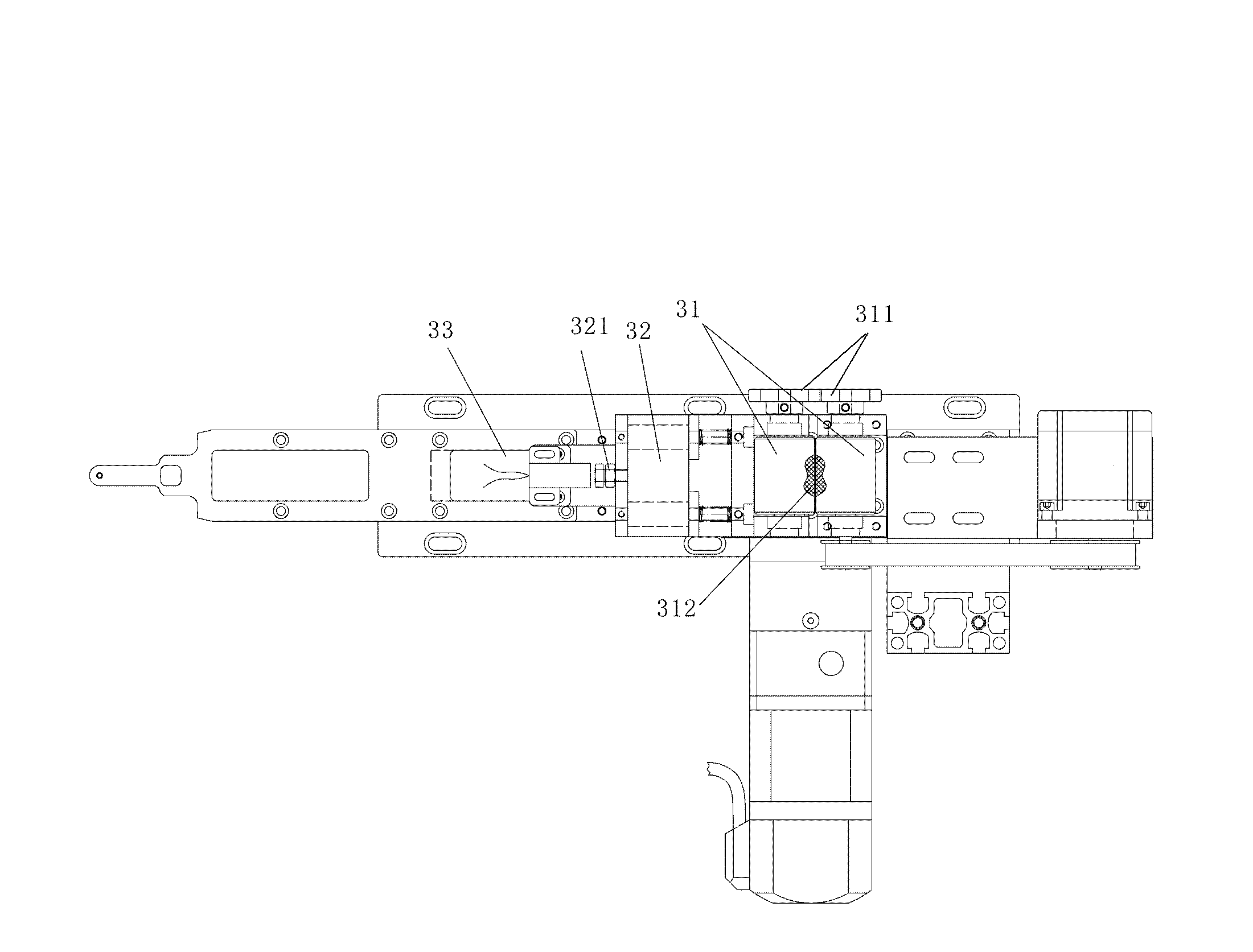

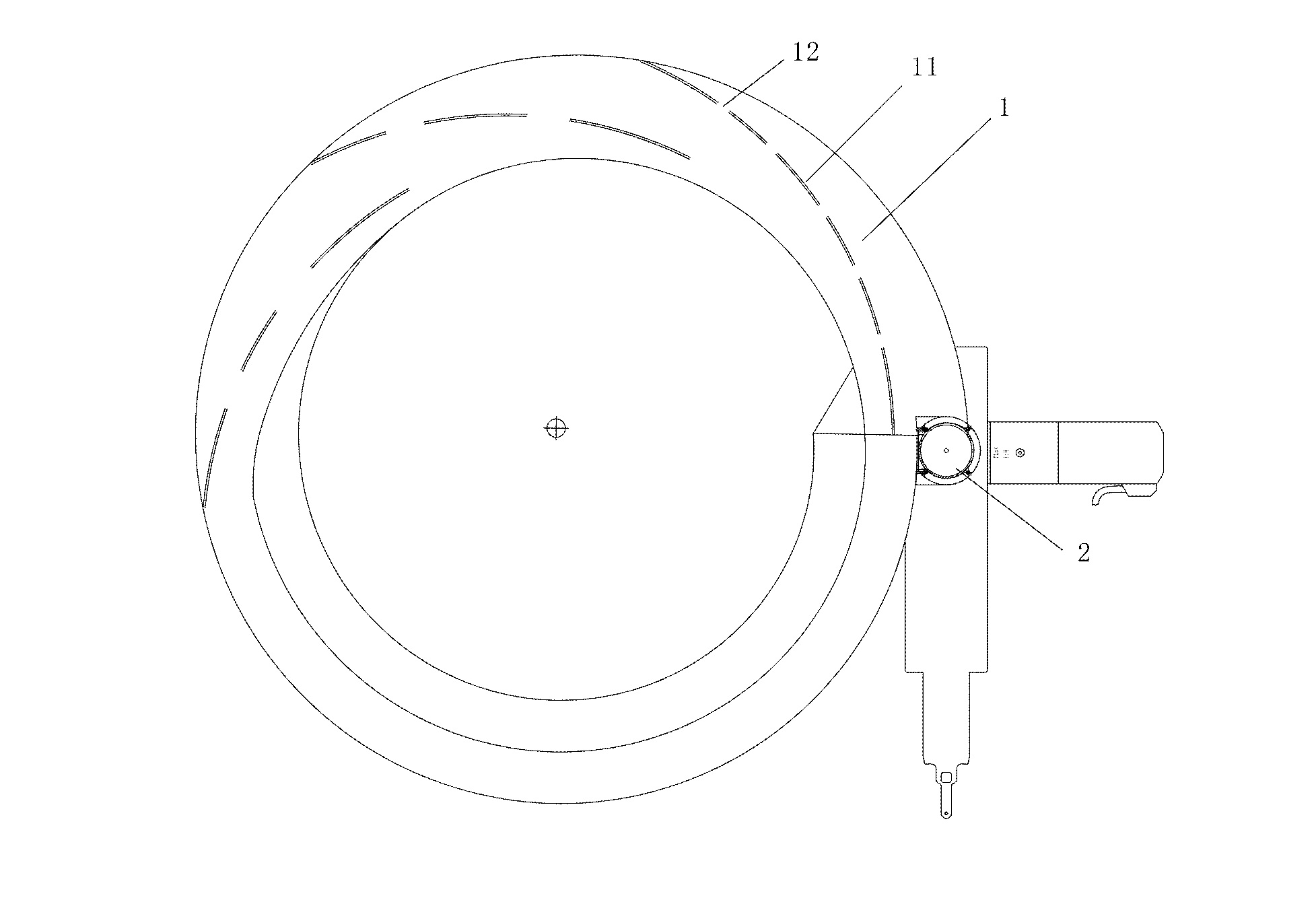

[0021] like Figure 1 to Figure 5 As shown, a kind of badminton feather piece automatic straightening and hair feeding device comprises a hair feeding hopper 1, a hair selection cylinder assembly 2, a hair feeding wheel assembly 3, a turning wheel assembly 4 and a hair sending assembly 6 connected in sequence. The bucket is provided with a plurality of centripetally deflected material baffles 11, and the material baffles 11 are provided with a plurality of pores 12. The basic structure of the wool feeding hopper 1 is a vibrating hopper in the prior art. Each step on the hopper faces outwards with a certain inclination. For centripetal deflection, each baffle plate 11 is provided with inlet pores 12. When the feathers vibrate in the hopper, they will move outward along the slope on the hopper. The inlet pores 12 can select the feathers moving forward to a certain extent. Make the flakes with hair stems ahead can continue to pass through the pores 12 and move forward, while the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com