Phase change ink compositions and colorants for use in the same

A technology of phase change ink and composition, which is applied in ink, application, household appliances, etc., and can solve problems such as inability to use colorants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 and 2

[0052] Formulation of Phase Change Inks of Embodiments of the Invention

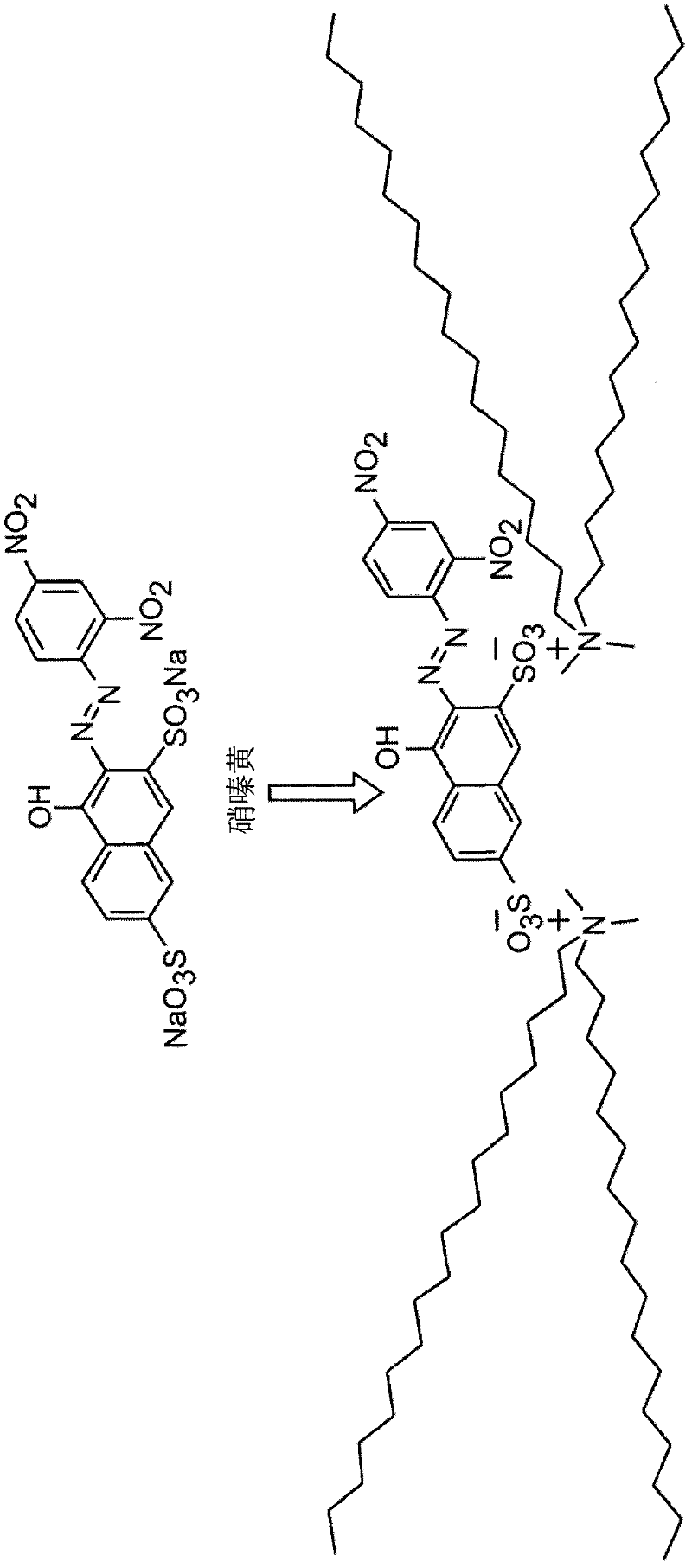

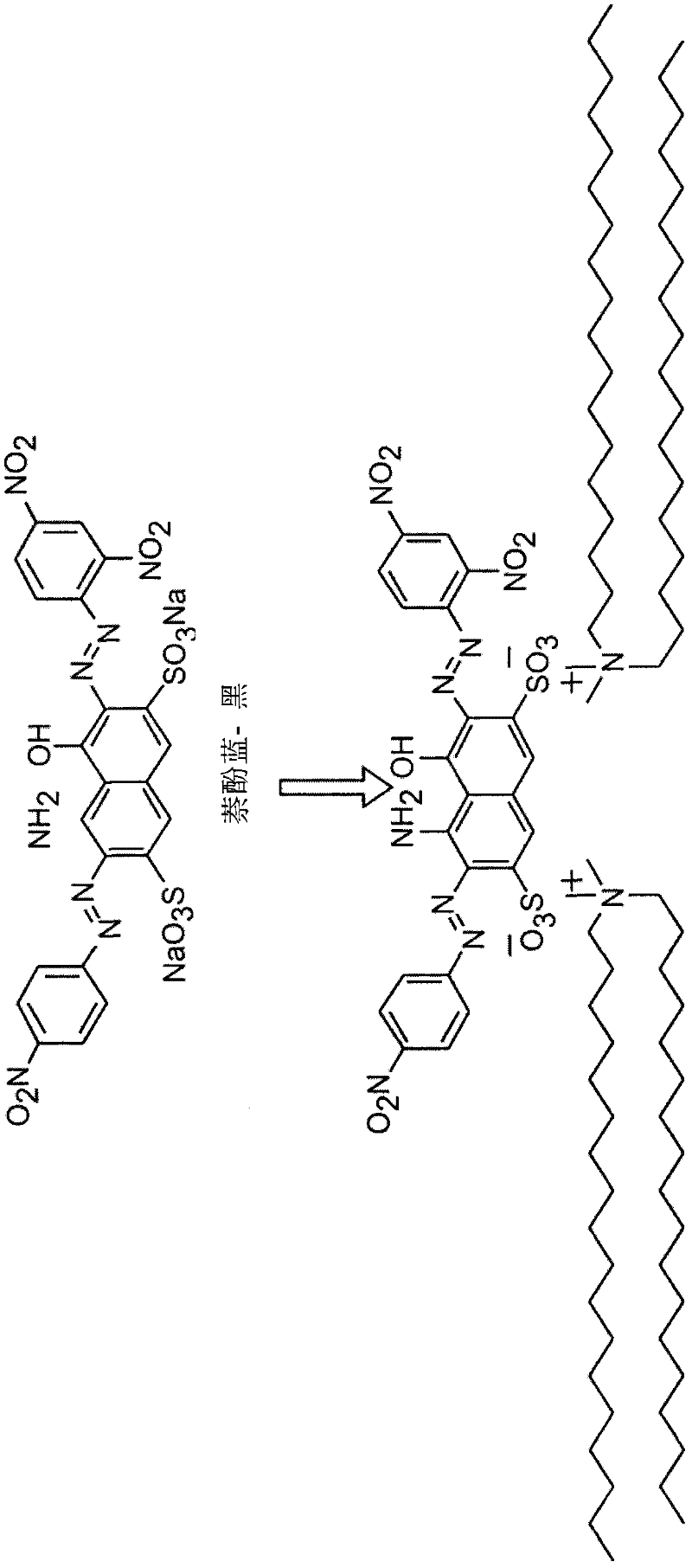

[0053] Colorants (naphthol blue-black, nitrazine yellow) and N,N-dimethyldioctadecyl bromide (N,N-dimethyldioctadecyl bromide) are commercially available from Sigma Aldrich. The modified naphthol blue-black and nitrazine yellow compounds can be obtained by combining a commercially available colorant with N, N-dimethylbis(octadecyl) bromide and colorant p-ammonium bromide 1: 2 ratio for the reaction to prepare. The reaction proceeded very rapidly in water at 80°C and the resulting insoluble compound was isolated by filtration using a glass frit.

Embodiment 1

[0055] Preparation of Phase Change Ink 1 Containing Modified Naphthol Blue-Black

[0056] In a 600ml beaker, add the following: 26.7g of KEMAMIDE S-180 (N-octadecyl octadecamide) (available from Crompton), 18.72g of triamide wax (as described in U.S. Patent No. 6860930 triamide), 80.69 g polyethylene wax (a polyethylene wax as described in U.S. Pat. and asymmetric molecular weight distribution skewed towards the high molecular weight end) (it can be obtained from Baker Petrolite), 18.72g KE-100 resin (available from Arakawa company), 2.56g polyurethane resin (it is stearoyl isocyanate The adducts of three equivalents and glycerol-based ethanol (can be prepared according to the method described in example 4 of US Patent 6309453)), 0.2 parts of Naugard-445 (an antioxidant, it can be obtained from Crompton company) and 8g SOLSPERSE 17000 (available from Lubrizol).

[0057]The material was melted in an oven at a temperature of 120°C and then transferred to a Union Process 01 gri...

Embodiment 2

[0059] Formulation of Phase Change Ink 2 Containing Modified Nitrazine Yellow

[0060] In a 1000 ml beaker, add the following: 53.4 g of KEMAMIDE S-180 (N-octadecyl octadecamide) (available from Crompton), 37.44 g of triamide wax (as described in U.S. Patent No. 6,860,930) described triamide), 161.38 g polyethylene wax (a polyethylene wax as described in US Pat. Dispersion and asymmetric molecular weight distribution skewed towards the high molecular weight end) (it can be obtained from Baker Petrolite), 18.72g KE-100 resin (available from Arakawa company), 5.12g polyurethane resin (it is stearyl Three equivalents of isocyanates and glycerol-based ethanol (can be formulated according to the method described in Example 4 of U.S. Patent 6309453)), 0.2 parts of Naugard-445 (an antioxidant) (it can be obtained from Crompton Corporation) ) and 16 g SOLSPERSE 17000 (available from Lubrizol).

[0061] The material was melted in an oven at a temperature of 120°C and then transferred...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com