Ceramic solar hot water tile

A solar water heating and ceramic technology, applied in roof drainage, renewable energy integration, roofing using tile/slate tile, etc. problems, to achieve the effect of reducing the overall cost, reducing weight, and good overall decoration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

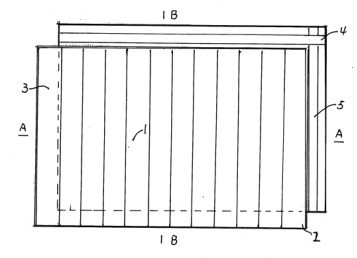

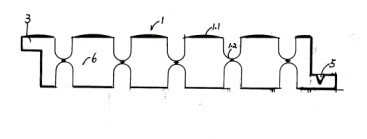

[0015] Embodiment 1: see Figure 1-3 , the ceramic solar water heating tile of the present invention is the same as the prior art. It is made of pottery clay and processed into grouting mud. Using ceramic mold injection molding, it is grouted once to form a hollow cube 1 with corrugated plates on the front and back, and the wave crest is 1.1 and The trough 1.2 (straight rainwater drainage groove) is opposite to each other ( figure 2 This structure is conducive to improving the structural strength of the ceramic hot water tile and reducing deformation during firing, and an air insulation layer is formed between the hot water tile and the roof), the hollow between the two wave plates is the water storage cavity 6, and the wave trough is 1.2 The two ends are slightly shallow, so that the water storage chambers formed by the wave crests are connected. On the sides of the hollow cube, along the upper and adjacent sides in the direction of the trough, the lower part of the thickne...

Embodiment 2

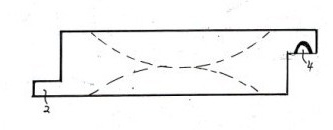

[0016] Example 2: see Figure 4 , as in Example 1, wherein heat-absorbing functional materials such as vanadium tailings or metal oxides are added to the ceramic mud to become ceramic mud with heat-absorbing function. There are two types of hot water tiles 7 and 8 for grouting molding, wherein 7 is a bottom tile structure, and the lower part of the thickness of the adjacent three sides of the peripheral side has a drainage groove 10 protruding outwards (only two sides are shown in the figure). The other side has an outwardly protruding covering edge (not shown in the figure) on the upper part of the thickness; Only two sides are shown), and the lower part of the thickness of the other side has a drainage groove protruding outward. The front of the hot water tile is a corrugated surface with drainage troughs 7.2 and 8.2 respectively, and the bottom surface is a flat bottom plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com