Particle filter and method for the purification of an exhaust-gas flow

A particulate filter and exhaust valve technology, which is applied to the electronic control of exhaust treatment devices, exhaust devices, exhaust treatment, etc., can solve problems such as damage to exhaust system parts and adverse effects on engine performance, and achieve extended time , Improve the effect of emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

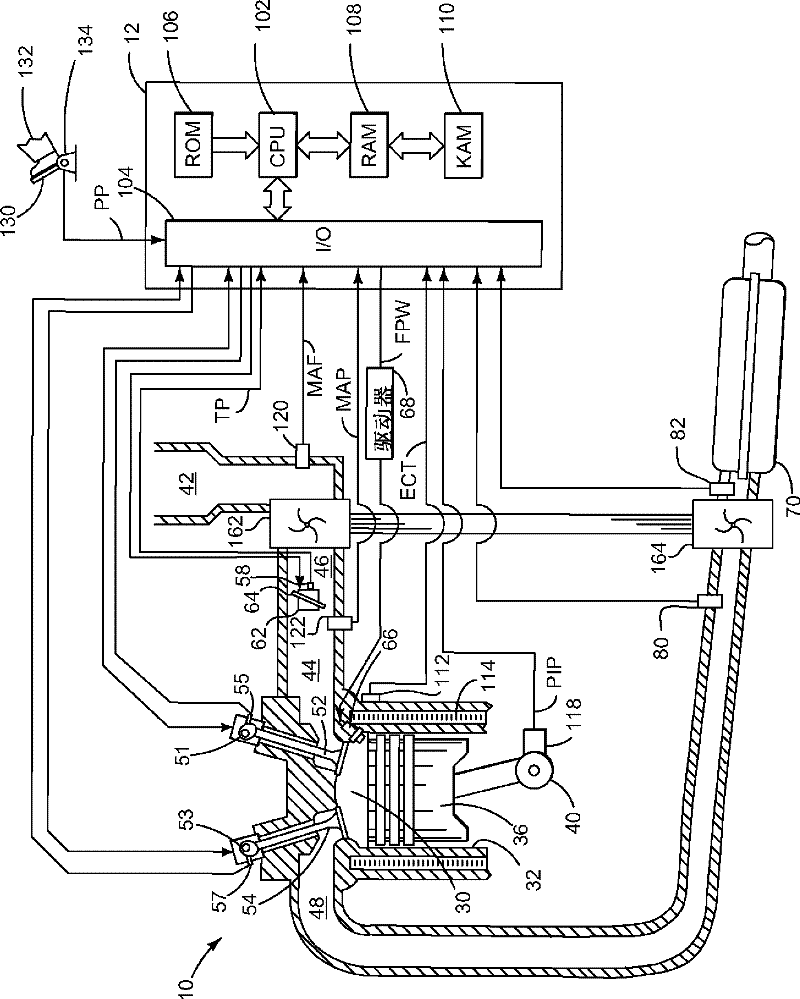

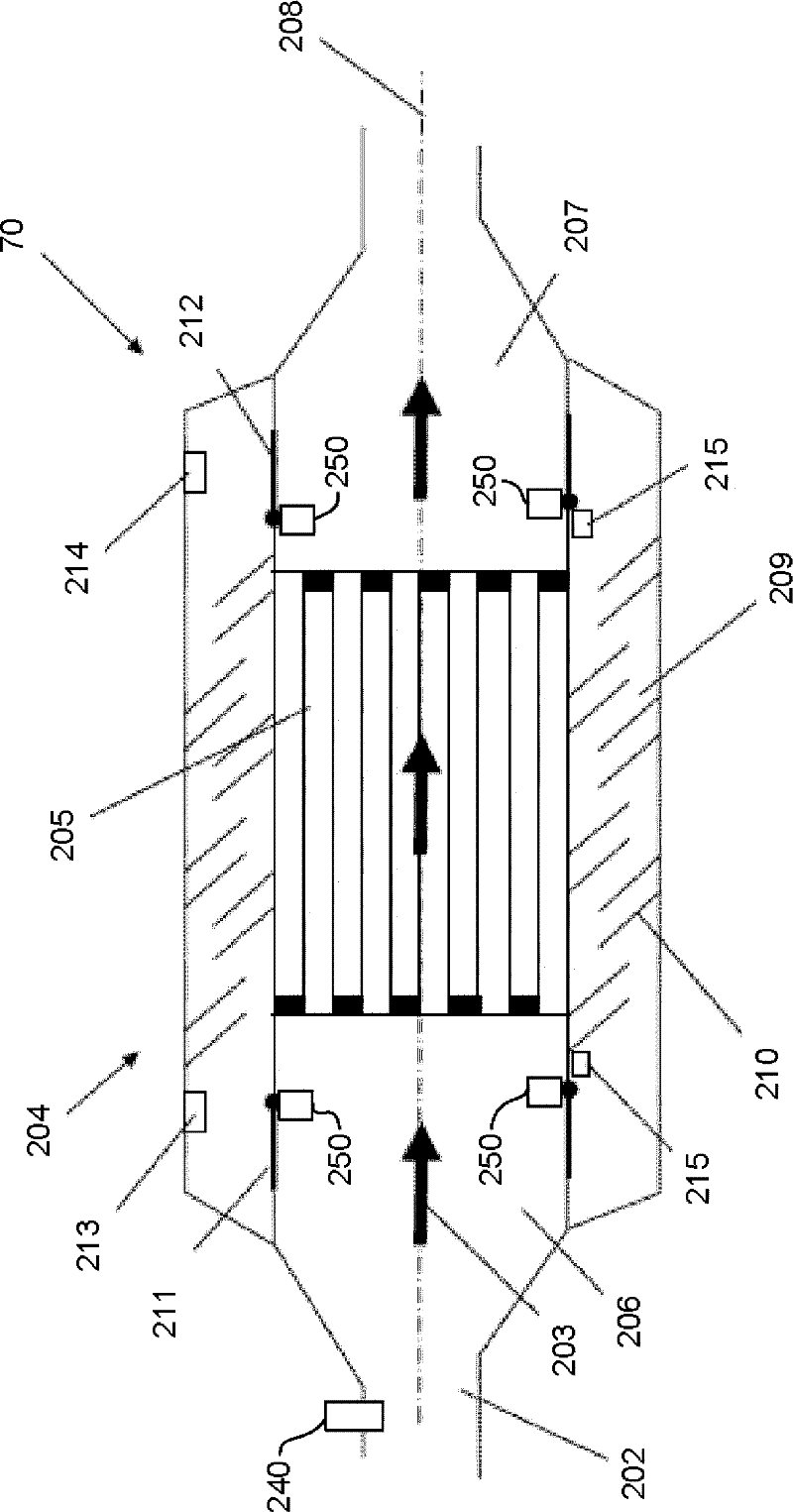

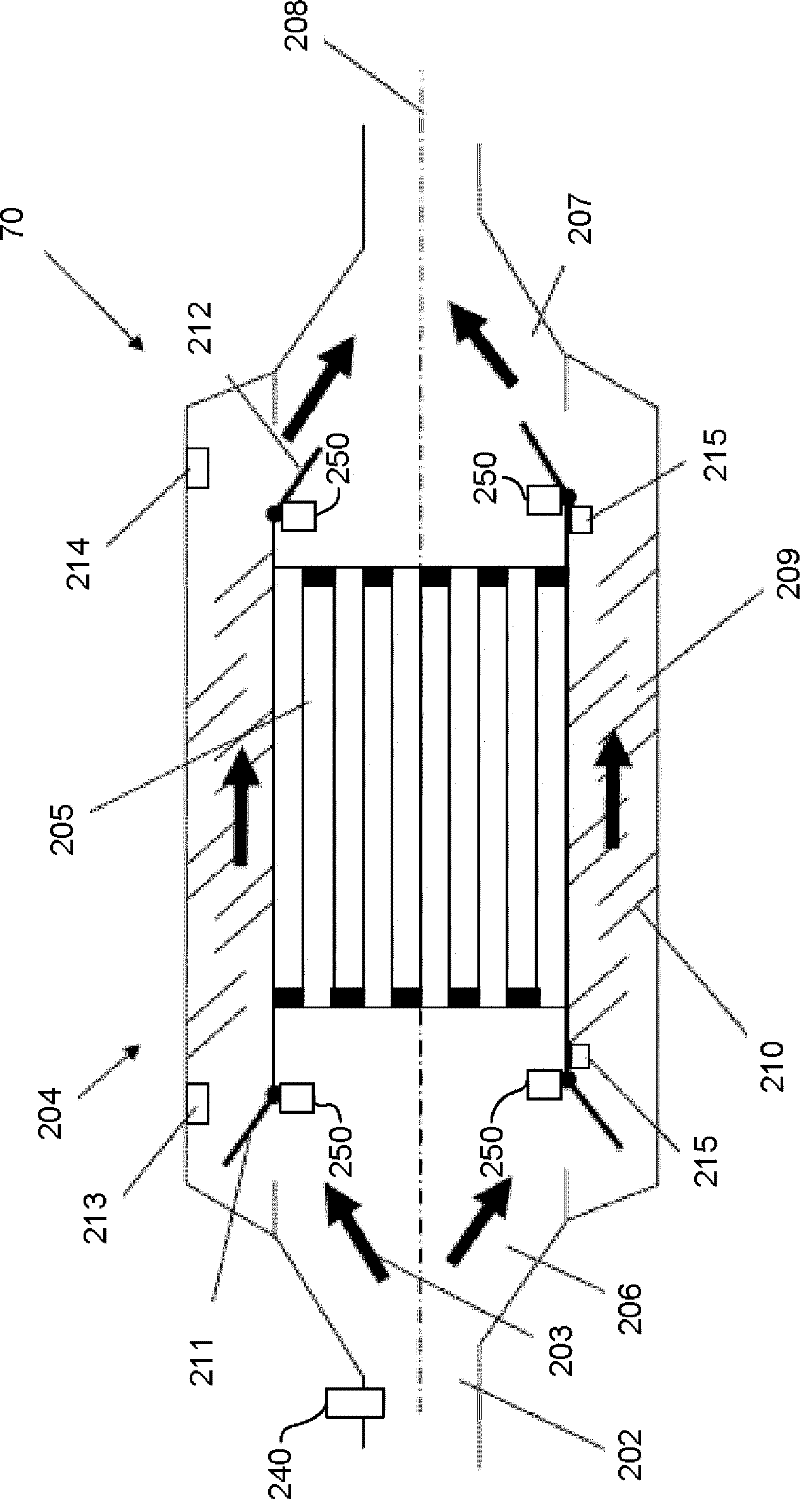

[0018] The invention relates to the operation of an engine directing exhaust gas to a particulate filter. In a non-limiting example, the figure 1 Engine configuration shown. figure 2 and image 3 Provides a detailed view of the two particulate filters and the exhaust routing system that directs the exhaust gas through the two particulate filters. Such as figure 2 As shown, exhaust gas may substantially only flow through the first particulate filter when the stored particulate matter in the first particulate filter is less than a threshold amount. Such as image 3 As shown, exhaust may flow through the second particulate filter when particulate matter stored in the first particulate filter is greater than a threshold amount. Figure 4 A method is provided for operating an engine and purifying engine exhaust via first and second particulate filters.

[0019] refer to figure 1 , an internal combustion engine 10 comprising a plurality of cylinders controlled by an electro...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap