Method and system for solving changes of exhaust gas recirculation (EGR) characteristic curves

A technology of characteristic curve and rate of change, applied in the field of solving the change of EGR characteristic curve, can solve the problems of inconsistent setting opening, deviation of EGR opening, fast aging speed, etc., and achieve the effect of eliminating adverse effects and improving exhaust gas recirculation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

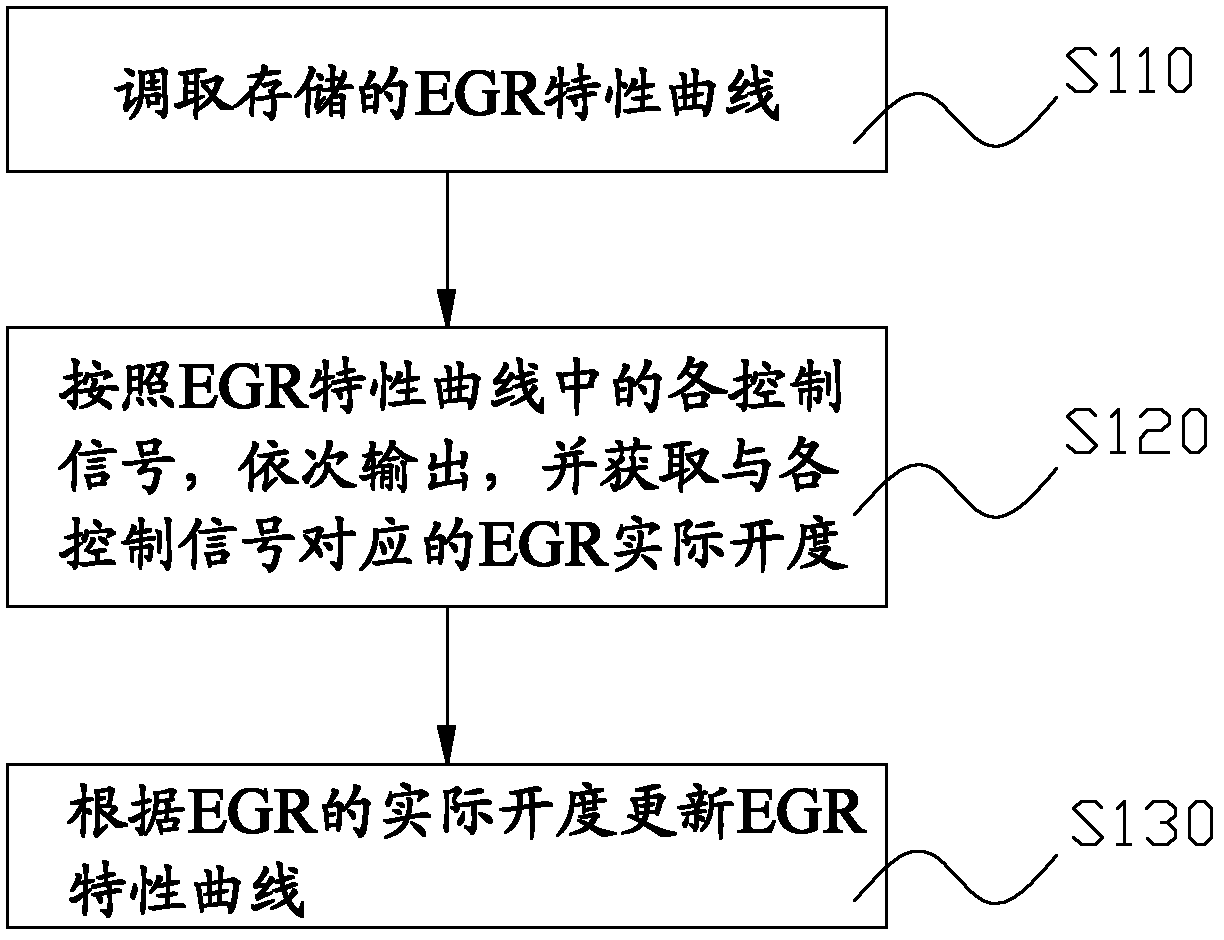

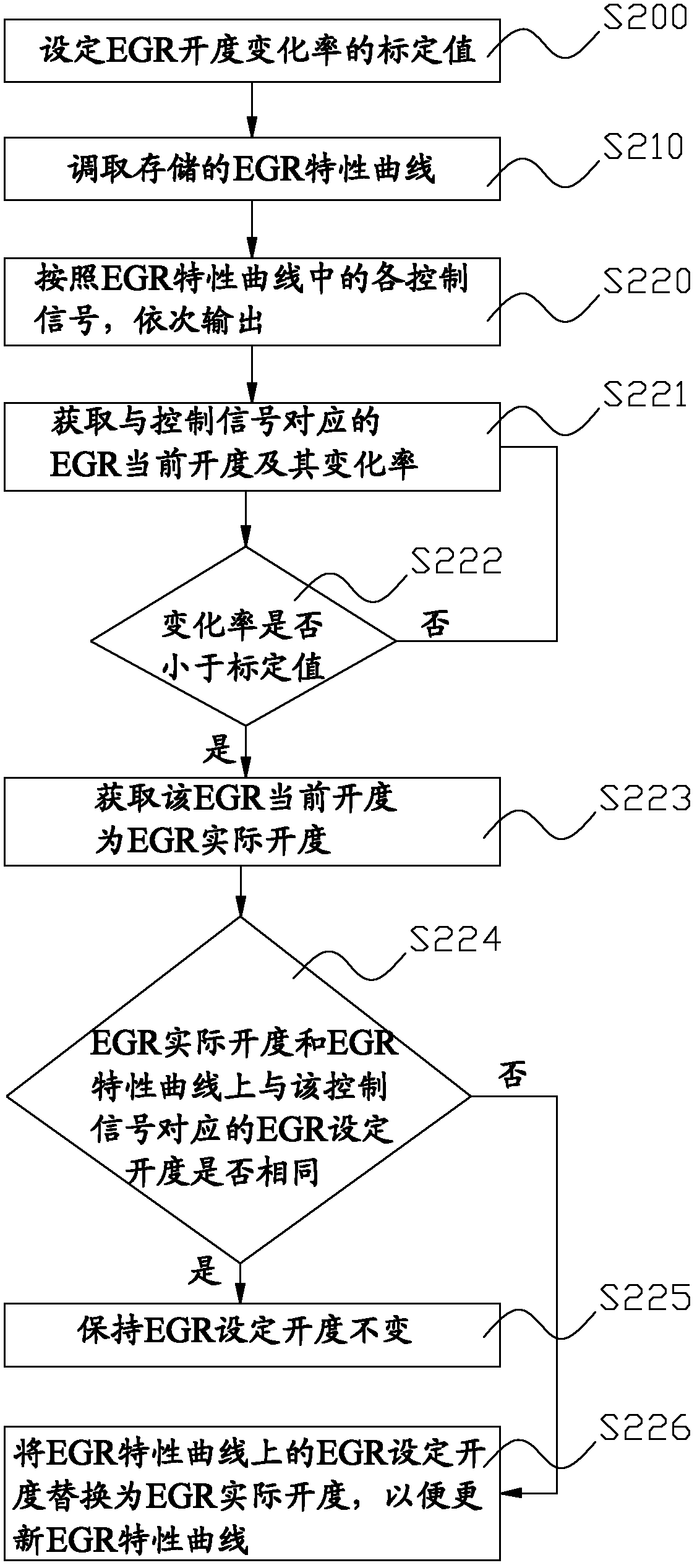

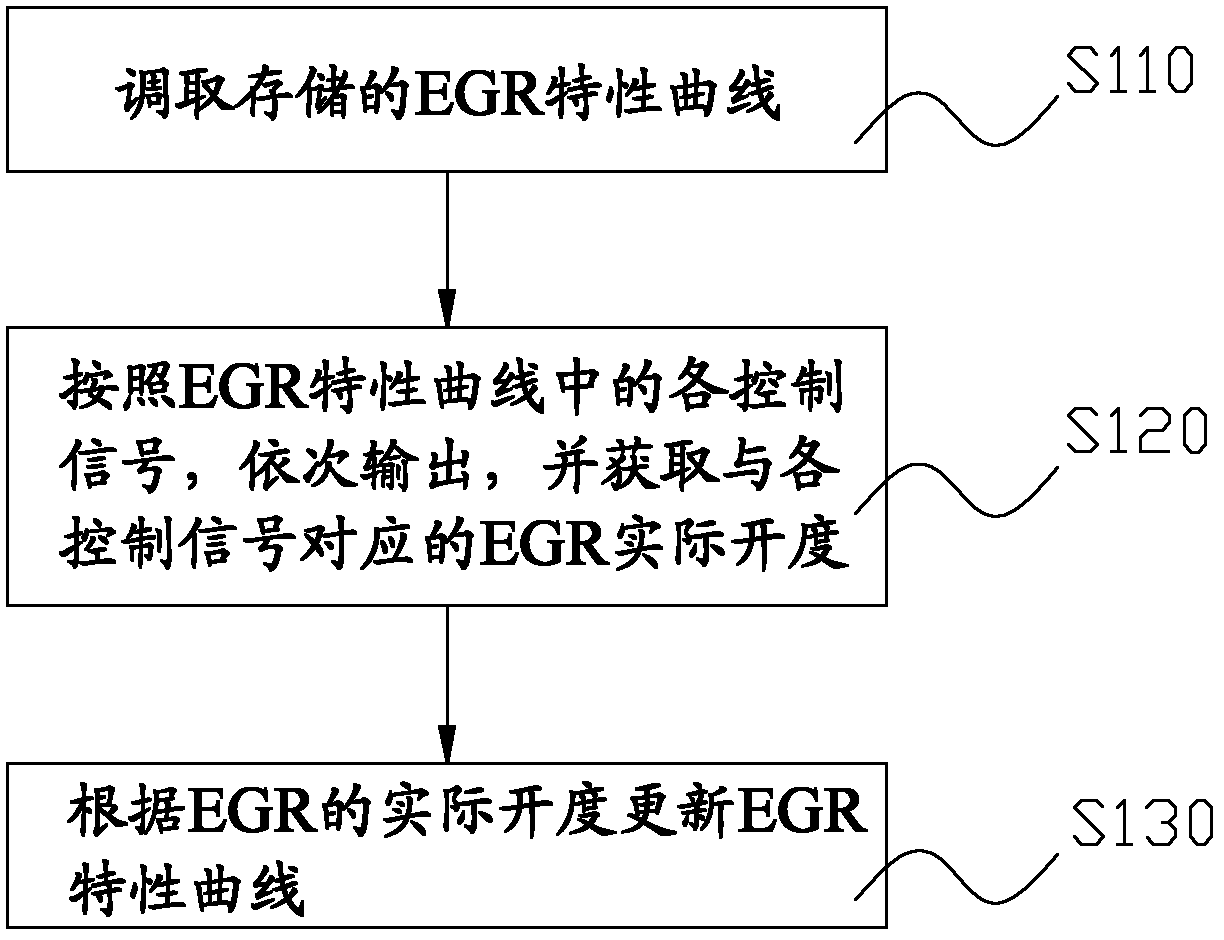

[0029] The core of the present invention is to provide a method and system for solving EGR characteristic curve changes, which can eliminate the influence of EGR curve changes on the EGR system work.

[0030] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. For ease of understanding and brevity of description, the method and system for solving EGR characteristic curve changes will be described below, and the beneficial effects will not be discussed repeatedly.

[0031] The system for solving the EGR characteristic curve change provided by the present invention mainly includes an EGR opening detection element, a test module and an update module. The main operation process of the system can be understood in conjunction with the following content.

[0032] Please refer to figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com