Vacuum generator

A vacuum generator and vacuum technology, applied in machines/engines, non-displacement pumps, mechanical equipment, etc., can solve the problems of large volume, heavy weight, and high energy consumption, and achieve small volume, light weight, and environmental adaptability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] A vacuum generator provided by the present invention uses compressed air as power, utilizes Bernoulli's principle, takes away the air around the vacuum generating sleeve, and generates vacuum.

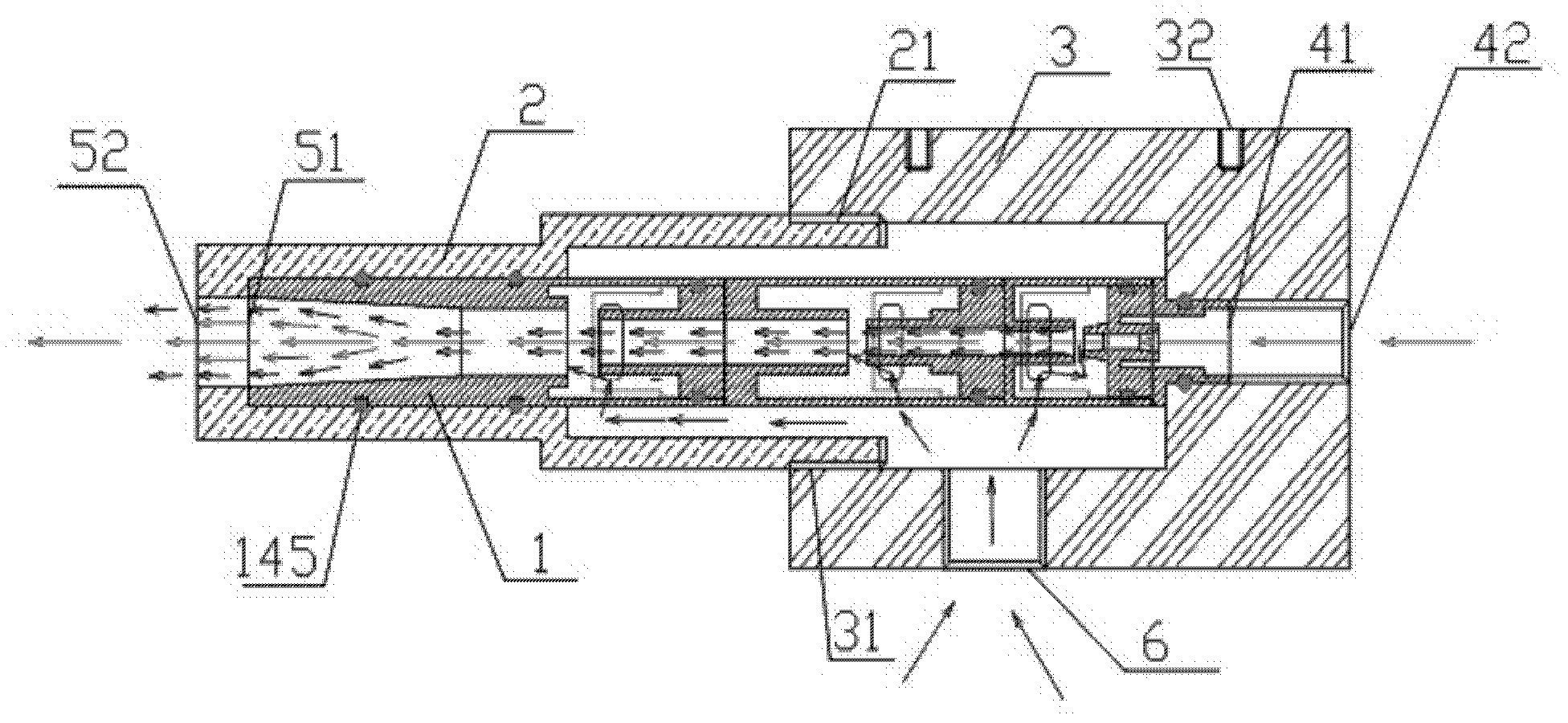

[0027] figure 1 It is a schematic cross-sectional view of a vacuum generator with a vacuum generating sleeve. like figure 1 As shown, the vacuum generator includes a vacuum generating sleeve 1 , a sleeve housing 2 and a vacuum generator base 3 .

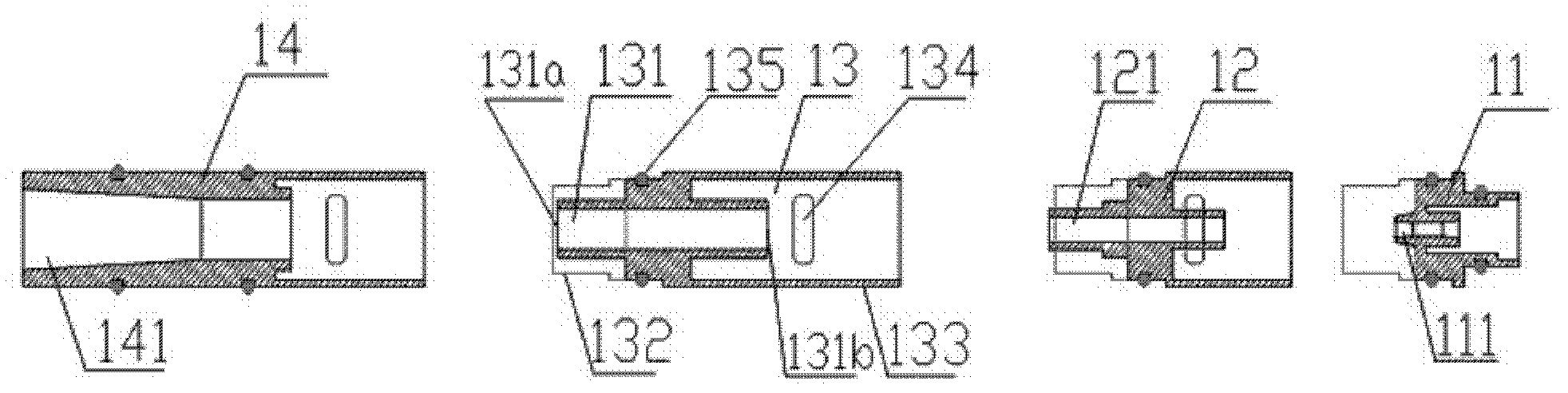

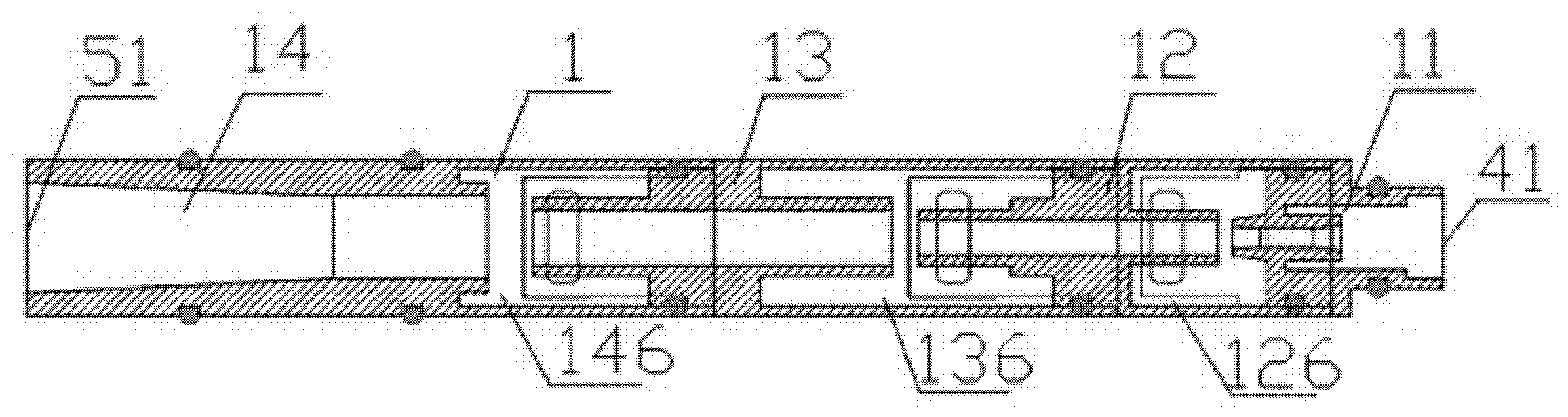

[0028] figure 2 It is a sectional disassembled view of several vacuum generating sleeve parts of the present invention. The vacuum generating sleeve of the present invention is made up of one or more sleeve parts, such as figure 2 The illustrated vacuum generating sleeve includes sleeve parts 11-14, but the number of sleeve parts is not limited thereto. The center position of each sleeve part has a nozzle 111, 121, 131 and 141 (hereinafter represented by 111-141) with different diameters, and the nozzle 111-141 is a through hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com