Blocking method suitable for drilling blasting and tool for same

A technology of tools and blastholes, which is applied in the field of plugging methods and tools used in the method, can solve the problems of affecting the health of construction workers on site, not reaching the air interval charge, time-consuming and high cost of plugging, and improving blasting efficiency. Effectiveness, good sealing performance, and the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] At first introduce the technical scheme of the present invention:

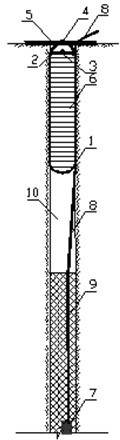

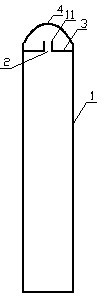

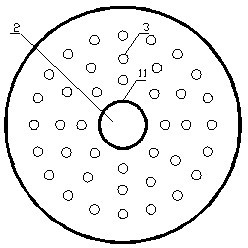

[0025] 1. According to the diameter of the blasthole to be blocked and the length of the blocked section, select the model of the customized cylindrical waterproof canvas water bag 1. The diameter of the canvas water bag 1 is 1-2cm larger than the diameter of the blasthole, and the length is 10cm longer than the blocked section. .

[0026] 2. Put the canvas water bag 1 into the blasthole after the charge of the blast hole is finished, the load-bearing belt 4 on the upper part of the canvas water bag 1 is supported on a load-bearing rod 5, the load-bearing rod 5 spans the hole of the blast hole, and the load-bearing rod 5 The end is more than 10cm away from the edge of the hole.

[0027] 3. Fill the canvas water bag 1 with water through the water injection hole 2 at the upper end of the canvas water bag 1. After the canvas water bag 1 is filled with water, tighten the water injection hole to seal the ca...

specific Embodiment approach

[0034] A mine adopts blasting mining, the drilling depth is 20m, the hole diameter is 200mm, the length of the blocking section is 3.0m, and the air interval is used for charging. The specific implementation of this technology is as follows:

[0035] (1) After the explosives are installed in the air-spaced charging section in the hole, the detonating index connected with the detonating bomb is drawn out of the hole.

[0036] (2) Put the custom-made waterproof canvas water bag 1 with a diameter of 210 mm and a length of 3.1 m into the hole, take a log load-bearing rod 5 with a diameter of 8 cm, pass through the load-bearing belt 4 on the upper part of the canvas water bag 1, and then place the log Across the blasthole orifice, the log ends shall have a minimum distance of 15 cm from the edge of the hole.

[0037] (3) Fill the canvas water bag 1 with water through the water injection hole 2 at the upper end of the waterproof canvas water bag 1 until the canvas water bag 1 is fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com