Caliper for bevel edge distance of membrane wall unit

A technology of unit bevel and membrane wall, which is applied in the field of measuring ruler, can solve the problems of inability to measure the center distance of the pipe and the length of the pipe, and achieve the effects of ensuring accuracy and operability, reasonable structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

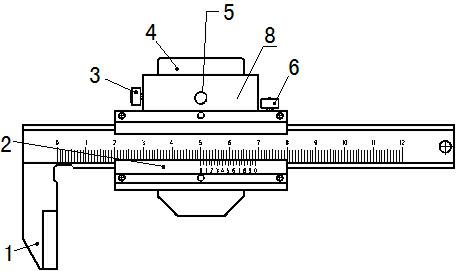

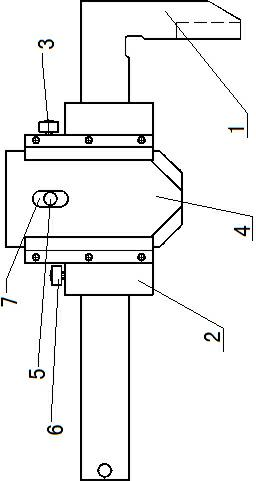

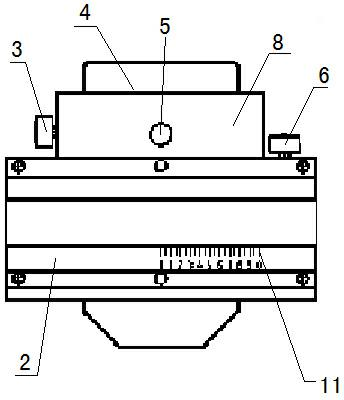

[0021] Embodiment 1: as figure 1 , 2 , 3, 4, 5, 6, and 7, a membrane-type wall unit bevel edge distance caliper includes a main ruler 1 with measuring claws, and a horizontal slide is movable on the ruler body of the main ruler 1 with measuring claws. Seat 2, the horizontal positioning screw 6 is installed on the horizontal sliding seat 2, and the longitudinal sliding seat 8 is fixedly installed on the rear side of the horizontal sliding seat 2. Longitudinal positioning screw 3. The described transverse sliding seat 2 is vertically connected with the longitudinal sliding seat 8 by welding, and a transverse chute 9 is provided on the transverse sliding seat 2. The seat 8 is provided with a longitudinal chute 10, and the longitudinal slide rule 4 is installed in the longitudinal chute 10. The longitudinal sliding seat 8 is provided with a positioning stop pin 5 , and the longitudinal slide rule 4 is provided with a positioning hole 7 cooperating with the positioning stop pin ...

Embodiment 2

[0024] Embodiment 2: as figure 1 , 2 , 3, 4, 5, 6, and 7, a membrane-type wall unit bevel edge distance caliper includes a main ruler 1 with measuring claws, and a horizontal slide is movable on the ruler body of the main ruler 1 with measuring claws. Seat 2, the horizontal positioning screw 6 is installed on the horizontal sliding seat 2, and the longitudinal sliding seat 8 is fixedly installed on the rear side of the horizontal sliding seat 2. Longitudinal positioning screw 3. The described transverse sliding seat 2 is vertically connected with the longitudinal sliding seat 8 by welding, and a transverse chute 9 is provided on the transverse sliding seat 2. The seat 8 is provided with a longitudinal chute 10, and the longitudinal slide rule 4 is installed in the longitudinal chute 10. The longitudinal sliding seat 8 is provided with a positioning stop pin 5 , and the longitudinal slide rule 4 is provided with a positioning hole 7 cooperating with the positioning stop pin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com