Device and method for detecting elevator guide rail perpendicularity based on visual measurement

A technology for elevator guide rails and detection devices, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of inaccurate center positions of light spots and inability to realize automation, and achieve the effects of convenient operation, fast calculation speed, and reduced errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the protection scope of the present invention should not be limited thereby.

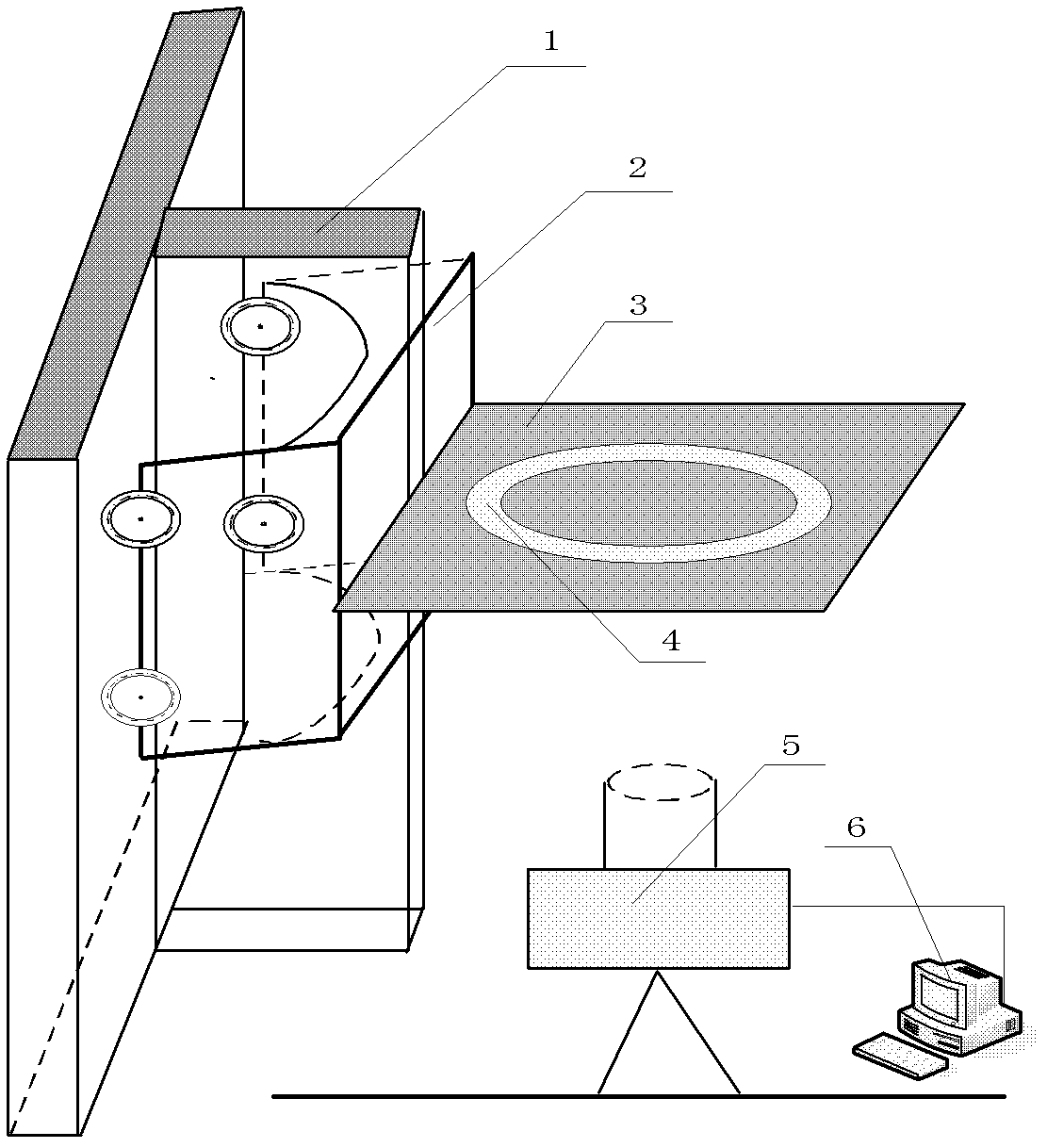

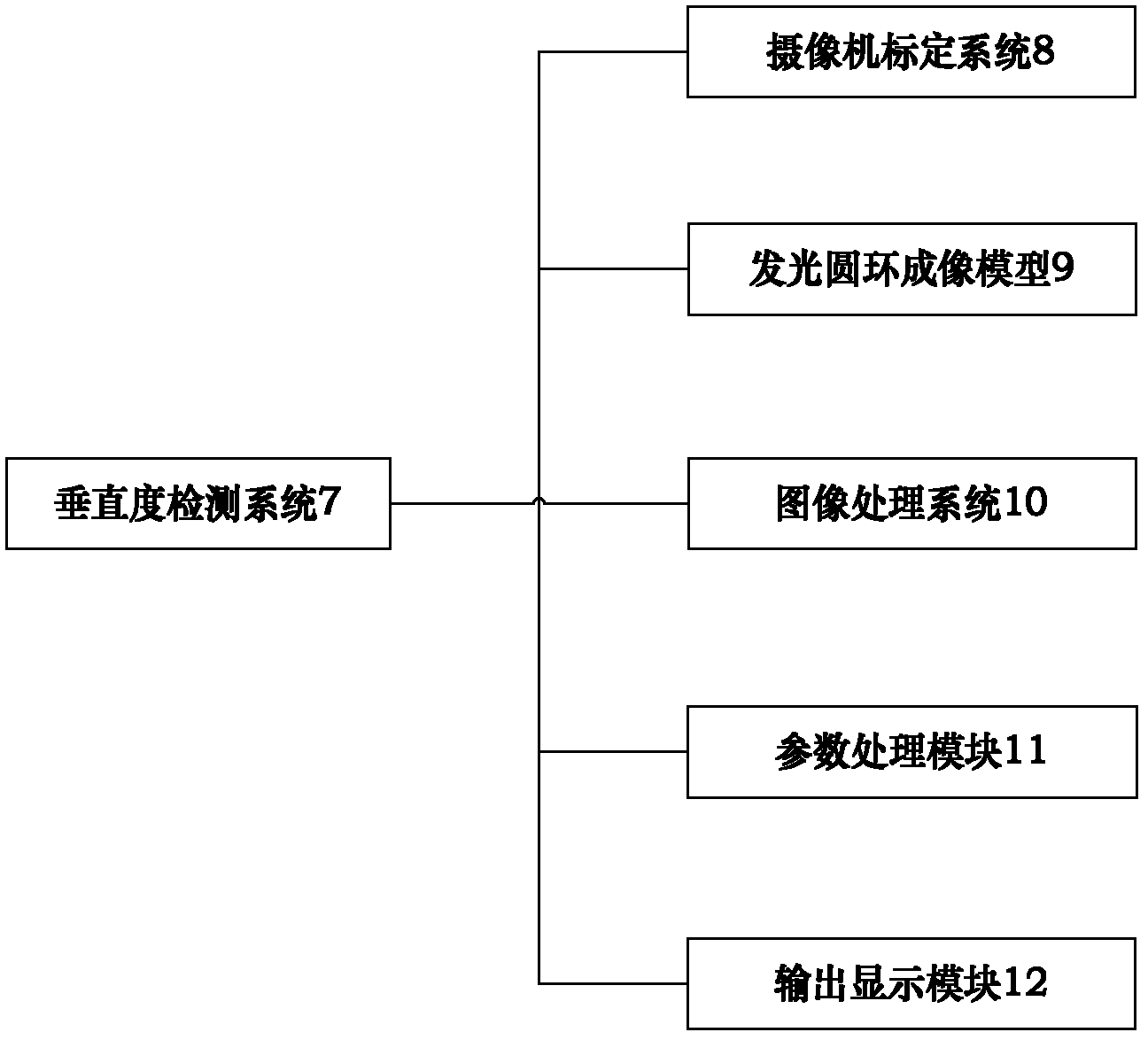

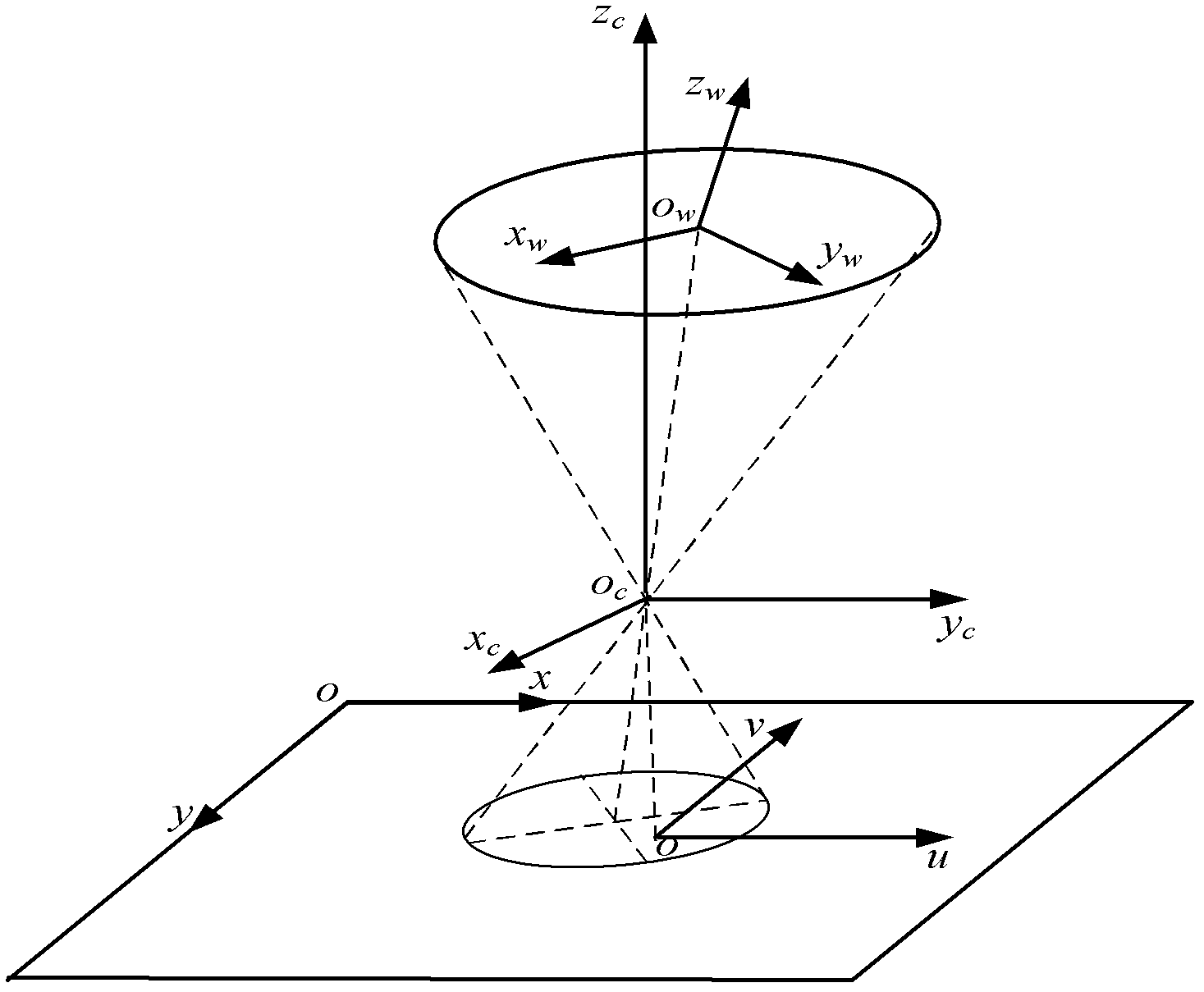

[0031] figure 1It is a structural schematic diagram of an elevator guide rail verticality detection device based on visual measurement in the present invention. It can be seen from the figure that a visual measurement-based elevator guide rail verticality detection device includes a verticality detection robot 2, an object stage 3, and a light-emitting ring 4 , video camera 5 and computer 6, described verticality detection robot 2 is vertical on the elevator guide rail to be tested, and described verticality detection robot 2 carries the light-emitting ring 4 on the loading platform 3 that is perpendicular to elevator guide rail 1 installation Running autonomously along the guide rail 1, the camera 5 is installed directly below the luminous ring 4, and the camera 5 is align...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com