Coal/shale adsorption capacity measuring device

A technology for measuring device and adsorption capacity, which is applied in the direction of measuring device, permeability/surface area analysis, suspension and porous material analysis, etc. It can solve the problem that the measured temperature and pressure do not conform to the temperature and pressure environment, and cannot reflect the adsorption of coal rock/shale ability, inability to obtain more accurate data and other issues, to achieve the effect of balanced temperature conduction and distribution, good temperature conduction and distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

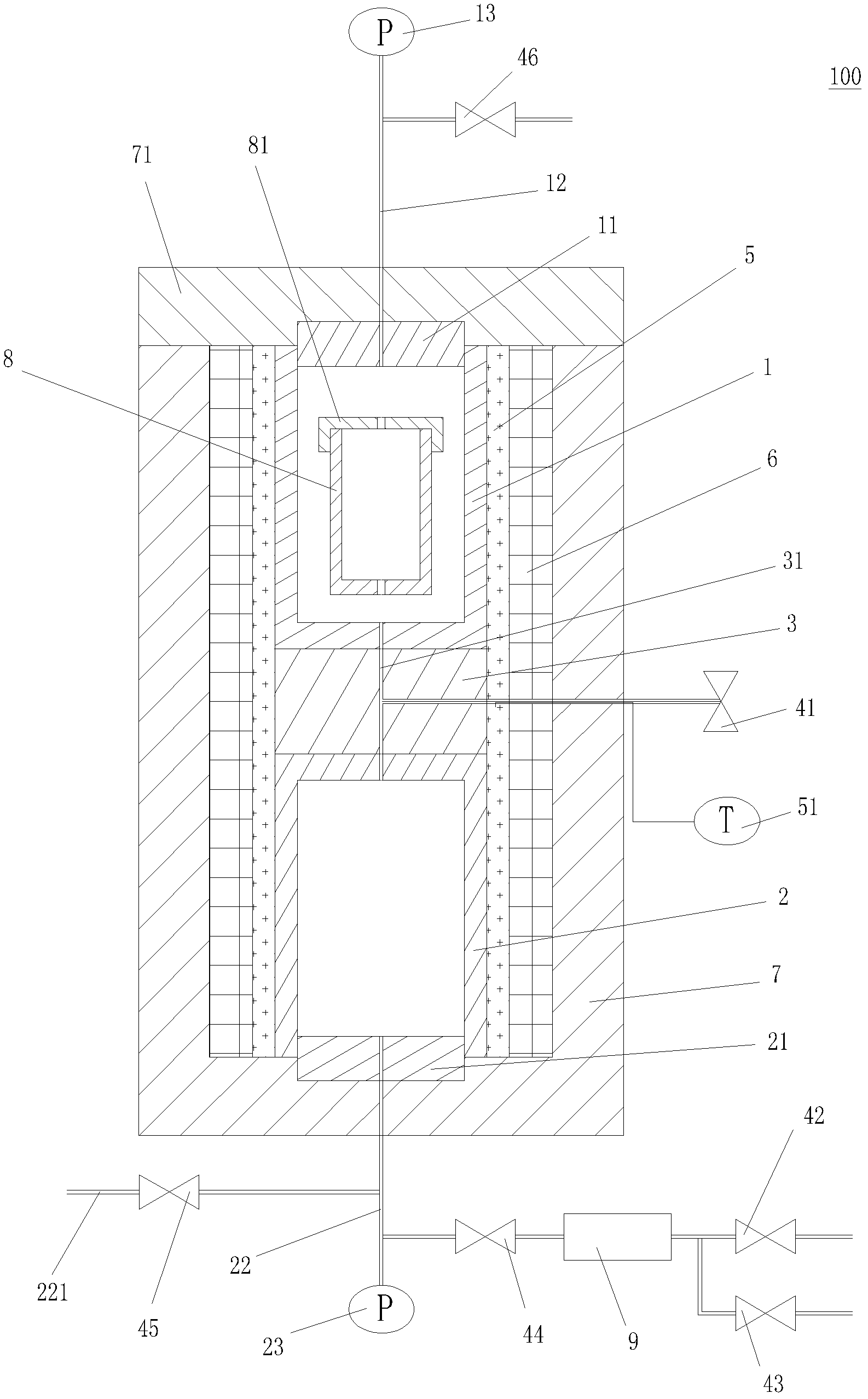

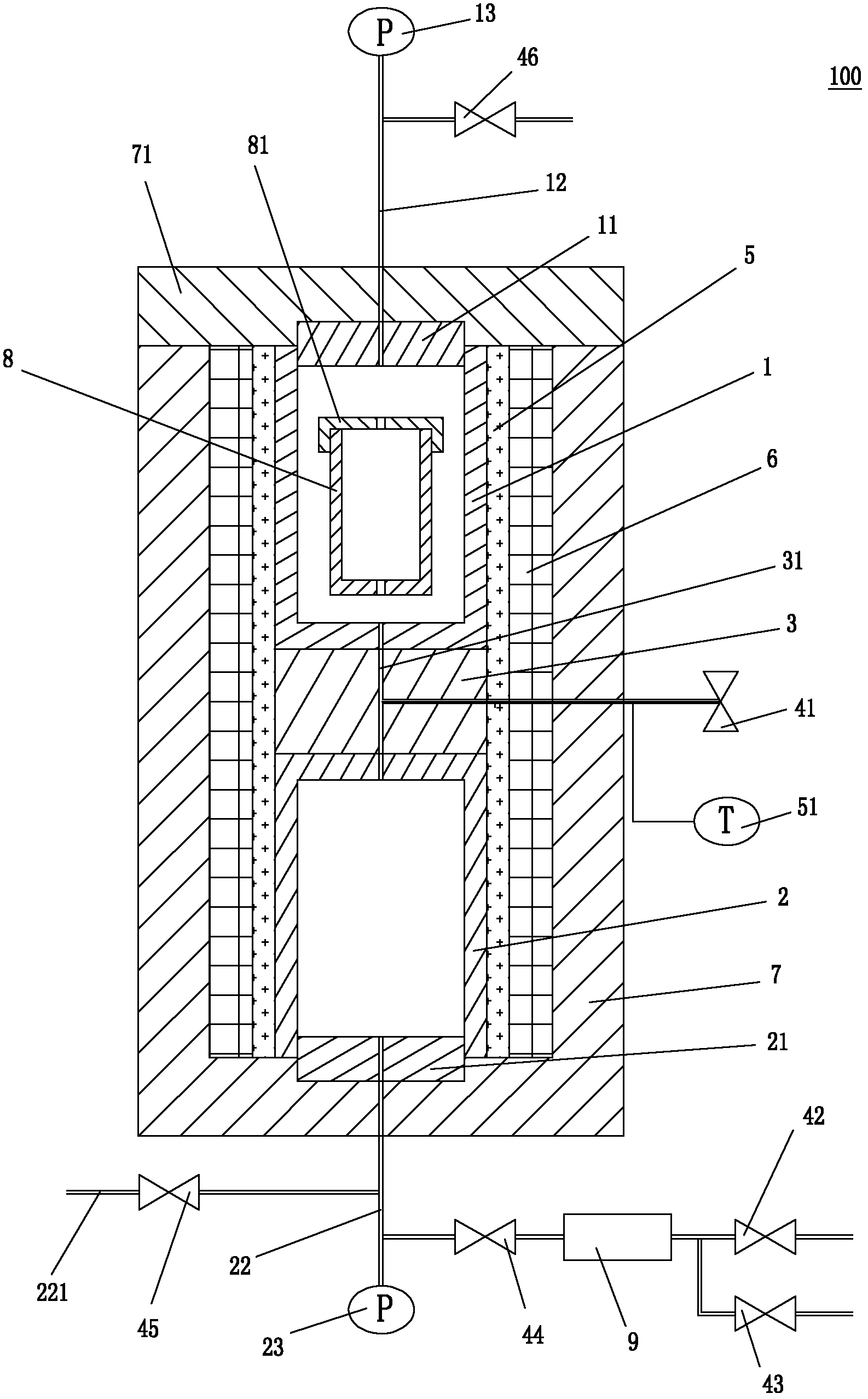

[0021] Such as figure 1 As shown, the present invention provides a coal / shale adsorption measurement device 100, the adsorption measurement device 100 includes an adsorption cylinder 1 and a reference cylinder 2 with the same diameter, the opening of the adsorption cylinder 1 is upward, and the opening of the reference cylinder 2 is towards Set up below, the cylinder bottoms of the adsorption cylinder 1 and the reference cylinder 2 are respectively fixed on the top surface and the bottom surface of a cylindrical steel block 3, the diameter of the cylindrical steel block 3 is the same as that of the adsorption cylinder 1 and the reference cylinder 2, The adsorption cylinder 1 and the reference cylinder 2 are connected by a connect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com