Method for determining and building bound water for crack-pore (hole) type reservoir core

A technology of bound water and rock core, applied in the preparation of test samples, analysis of suspensions and porous materials, measuring devices, etc., can solve the problem that the test results are not representative, the saturation of bound water cannot be accurately determined, and bound water meets the requirements Value and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The method for determining and establishing the irreducible water of the fracture-pore (cavity) type reservoir core includes the following steps in sequence:

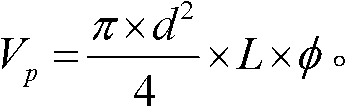

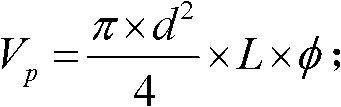

[0019] (1) Select the unfractured reservoir core, measure its diameter d and length L, and measure the porosity φ of the core 0 and permeability K 0 , as the porosity and permeability parameters of the bedrock;

[0020] (2) Formation water is prepared according to the analysis data of formation water samples on site, and simulated oil is prepared according to the viscosity ratio of formation oil and water;

[0021] (3) For gas reservoir cores, the cores are cleaned and evacuated to saturate the formation water, and the dry gas drives the water until no water comes out. The water saturation at this time is the irreducible water saturation S of the bedrock w0 ; For the reservoir core, after the core is cleaned and evacuated, the formation water is saturated, and the simulated oil flooding formation water is used....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com