System and method for testing charge-discharge reliability of battery

A battery charging and battery discharging technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of expensive, cumbersome, and large error hardware equipment for testing batteries, and achieve the effect of fast testing speed and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

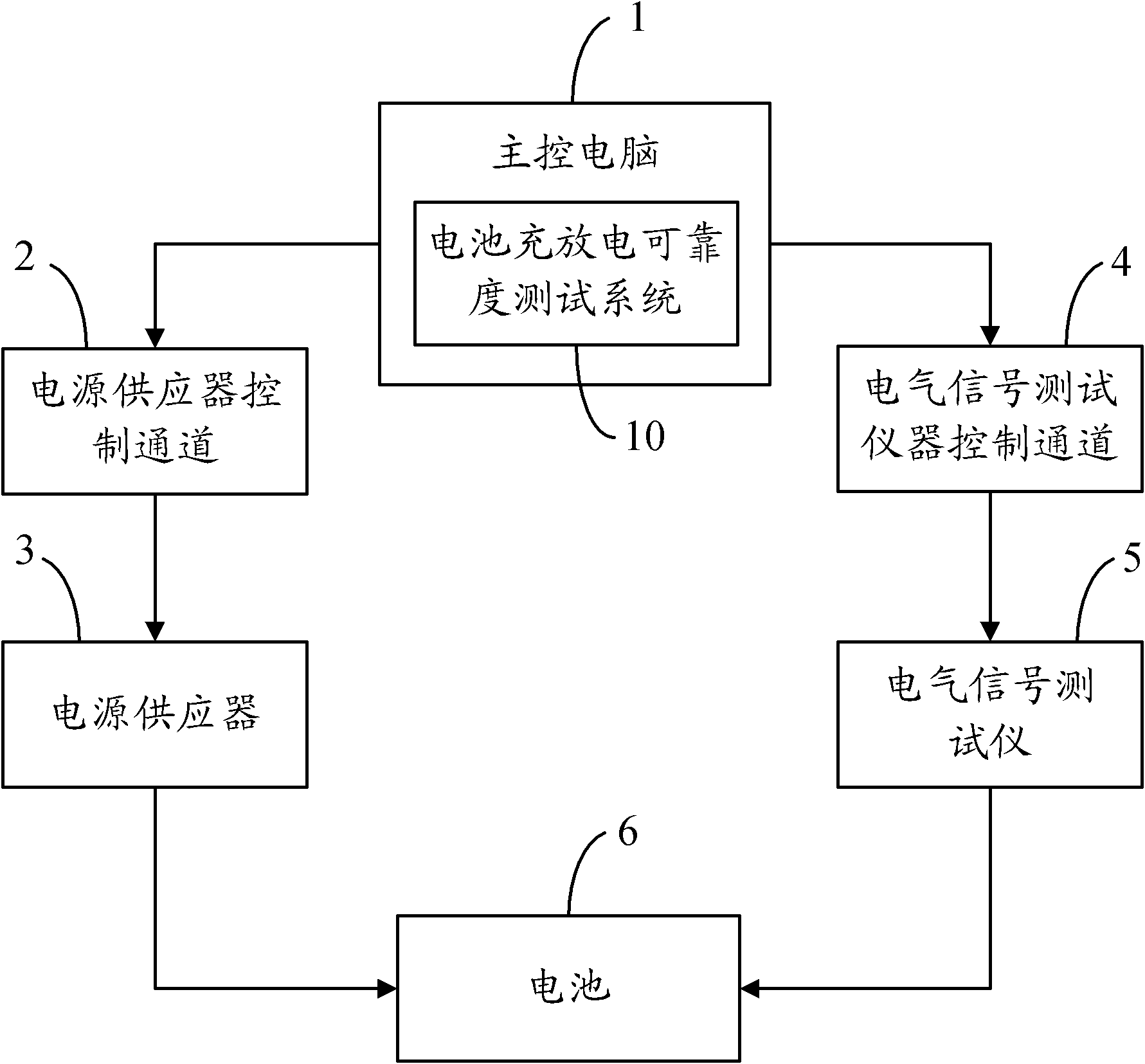

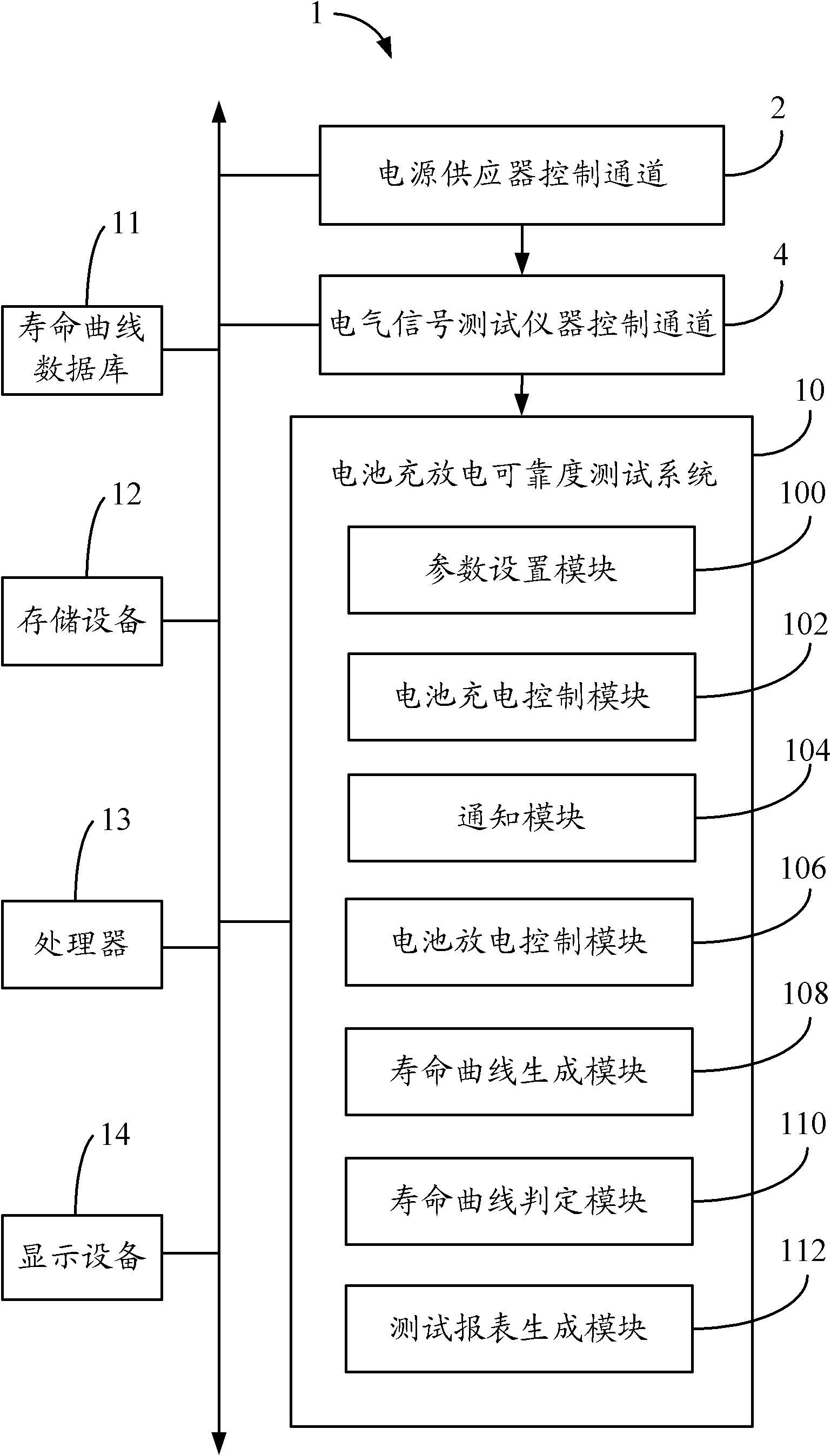

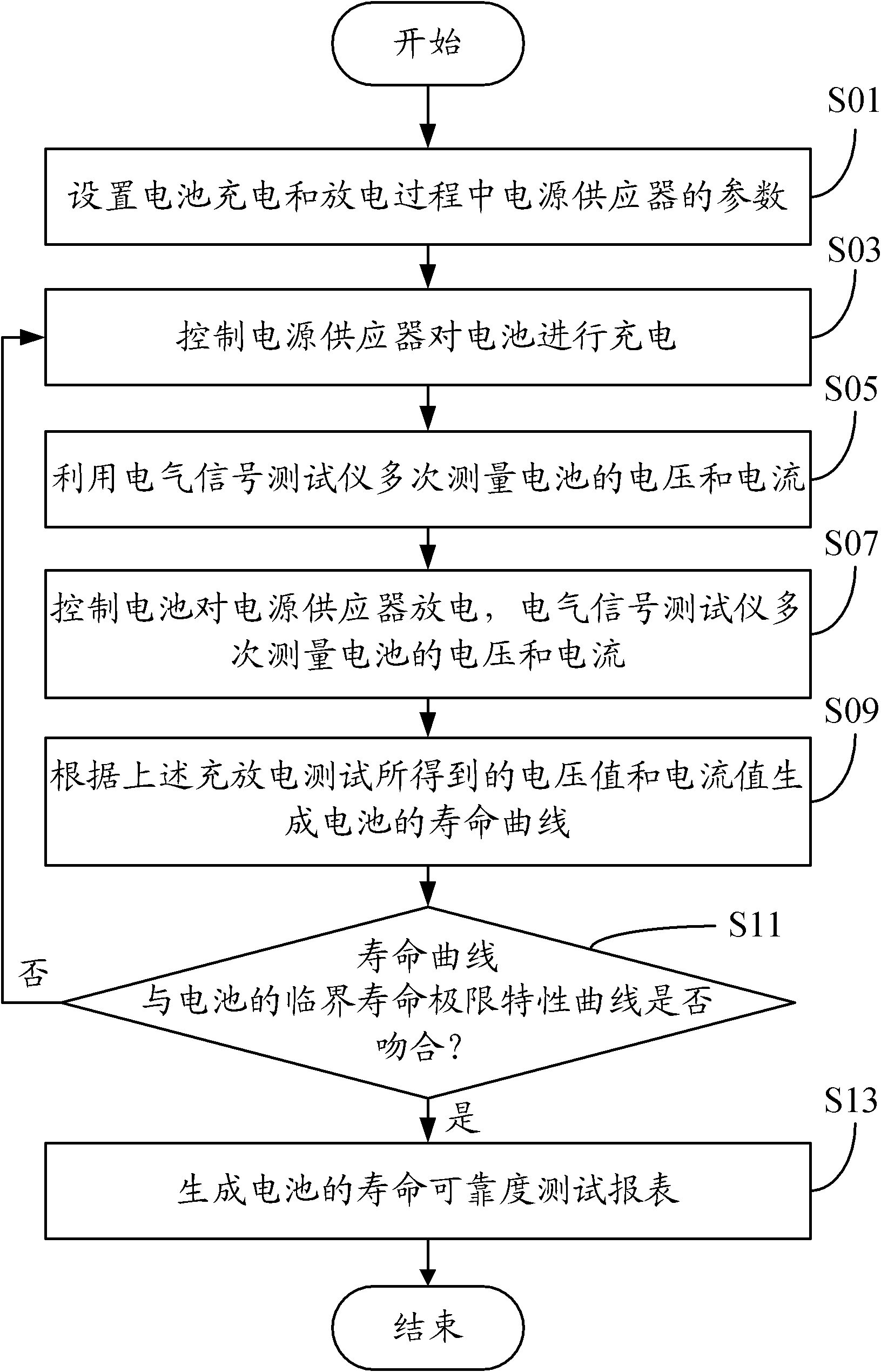

[0014] Such as figure 1 Shown is a schematic diagram of the operating environment of a preferred embodiment of the battery charging and discharging reliability testing system of the present invention. The battery charging and discharging reliability test system 10 runs in the main control computer 1 . The master computer 1 is connected to a power supply 3 through a power supply control channel 2, and is connected to an electrical signal tester 5 through an electrical signal tester control channel 4. The main control computer 1 controls the power supply 3 to charge and discharge the battery 6 through the battery charging and discharging reliability testing system 10, and measures the voltage and current of the charged and discharged battery 6 through the electrical signal tester 5, and The measured voltage and current values are stored in a lifetime curve database 11 . From the measured voltage value and current value, the reliability of charging and discharging of the batt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com