Reflective sheet, liquid crystal module and liquid crystal display

A liquid crystal display and liquid crystal module technology, which is applied in the direction of reflectors, instruments, lighting and heating equipment, etc., can solve the problems of weight increase, liquid crystal module cost increase, and volume increase, so as to avoid arching, wrinkling, and screen Effect improvement and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

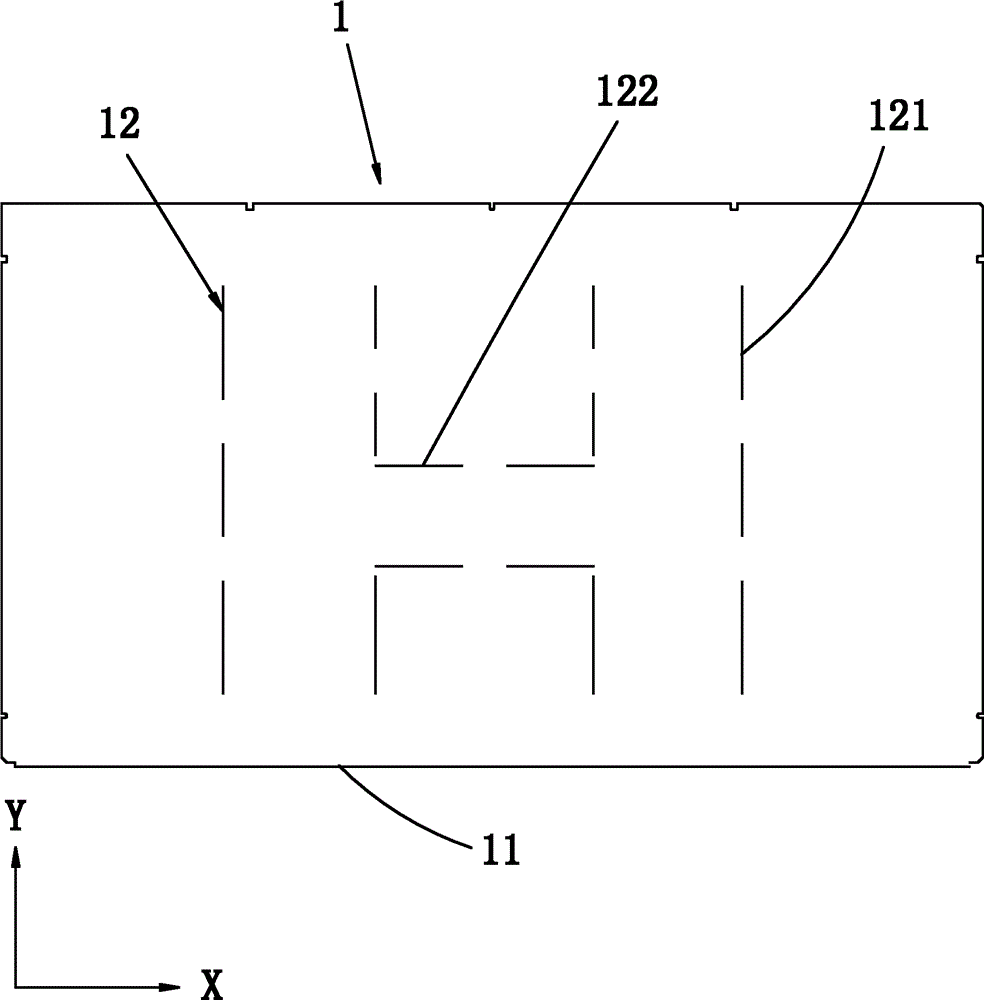

[0024] like figure 1 Shown is a preferred embodiment provided by the present invention.

[0025] The reflection sheet 1 provided in this embodiment is used in a liquid crystal module to reflect light emitted by a light source in the liquid crystal module. As shown in the figure, the X direction is defined as the horizontal direction of the plane of the reflective sheet 1 and the Y direction is defined as the vertical direction of the plane of the reflective sheet 1 .

[0026] In order to uniformly reflect the light source, the reflector 1 in this embodiment is a planar body, on which there is a linear structure 12 that runs through the upper and lower end surfaces of the reflector 1, and the linear structure 12 can divide the reflector 1 into several interconnected The blocks together, that is, the linear structure 12 penetrates the upper and lower end surfaces of the reflective sheet 1 in the longitudinal direction, but in the plane direction, and does not penetrate the refl...

Embodiment 2

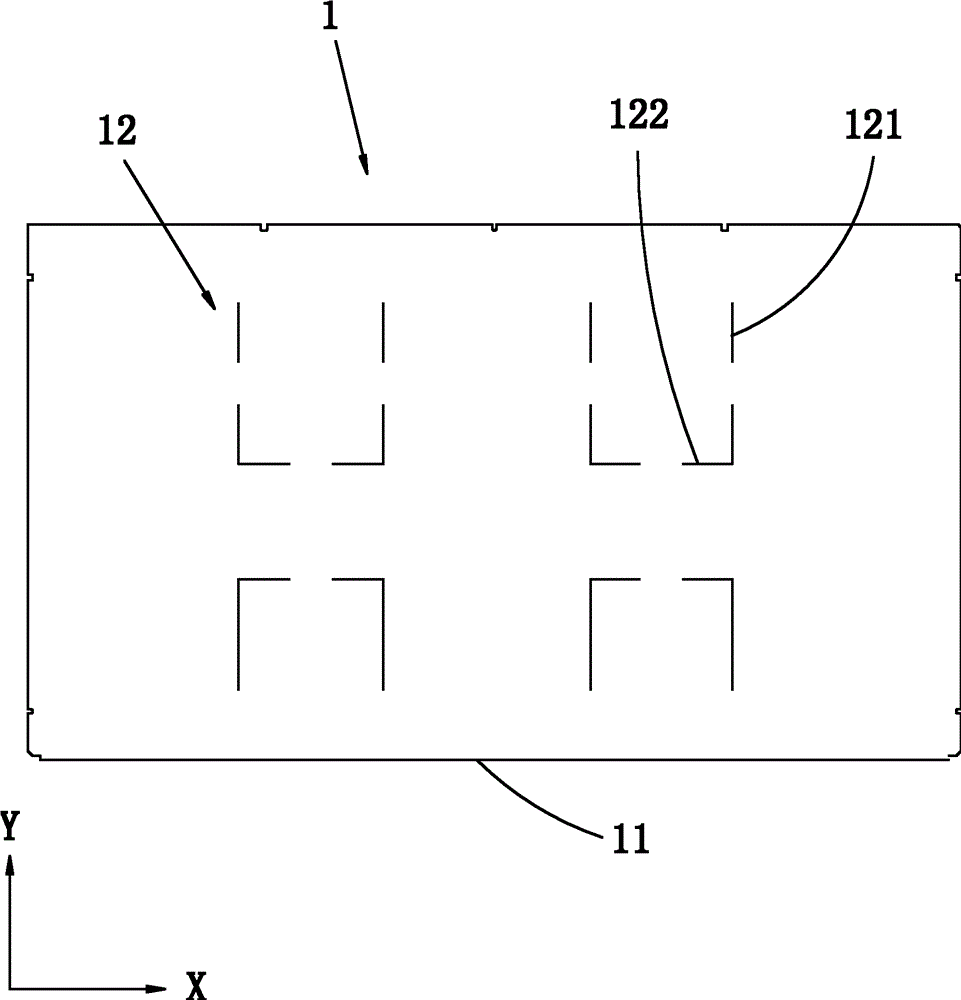

[0038] like figure 2 Shown is another preferred embodiment provided by the present invention.

[0039] The difference between this embodiment and Embodiment 1 is that the dotted lines in this embodiment include eight vertical dotted lines 121 and four horizontal dotted lines 122, wherein each horizontal dotted line 122 is respectively connected with two vertical dotted lines 121 to form an open body, In this way, the dotted line forms four openings, and these four openings are distributed symmetrically about the center of the reflection sheet 1 .

[0040] Specifically, the four opening-shaped bodies are distributed in two rows, and the openings of the opening-shaped bodies in each row have the same opening orientation, and the openings of the opening-shaped bodies in different rows face away from each other.

Embodiment 3

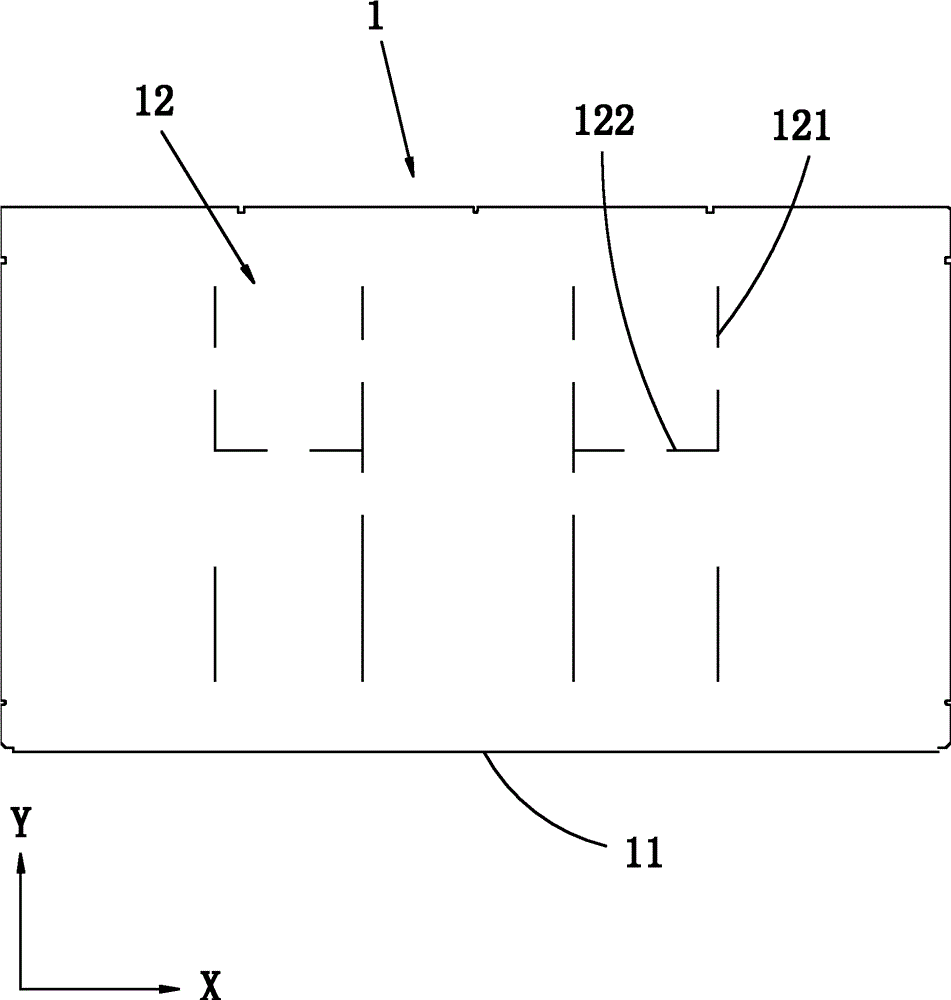

[0042] like image 3 Shown is another preferred embodiment provided by the present invention.

[0043] The difference between this embodiment and Embodiment 1 is that the dotted lines in this embodiment include two horizontal dotted lines 122 and eight vertical dotted lines 121, wherein each horizontal dotted line 122 is respectively connected with two vertical dotted lines 121 to form an open body, In this way, the dotted lines of the reflective sheet 1 form four vertical dotted lines 121 and two openings, which are symmetrically distributed on the reflective sheet 1 with respect to the center of the reflective sheet 1 .

[0044] Specifically, the openings of the two opening-shaped bodies have the same orientation and are arranged side by side, a vertical dotted line 121 on the opening-shaped body extends downward, and the other four vertical dotted lines 121 are arranged side by side and arranged below the two opening-shaped bodies.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com