Fast positioning and corresponding method for machining features and machining operations

A technology of machining features and machining procedures, which is applied in the field of fast positioning and corresponding processing of machining features and machining operations of large parts, which can solve the problems of repetition of wrong operation simulation, affecting simulation, and increasing workload, etc. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

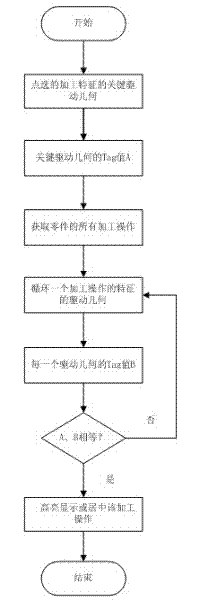

[0027] figure 1 It is a flow chart of the method for fast positioning and corresponding processing features and processing operations of the present invention, as shown in the figure, including the following steps:

[0028] Before finding an operation, it is necessary to clarify the type of operation and define the key driving geometry of each operation.

[0029] The principle of defining the key driving geometry of an operation is: 1) the core element among all driving elements of a certain operation; 2) the user is easy to click;

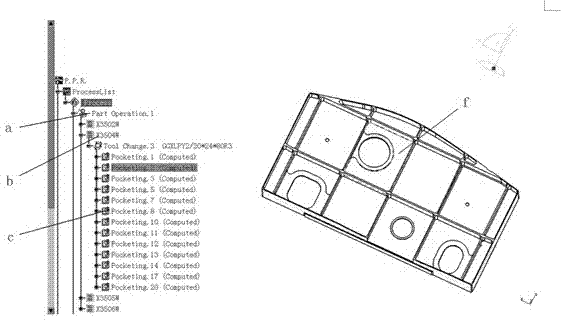

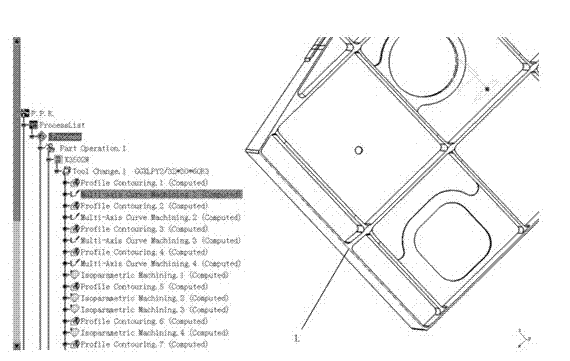

[0030] Before filtering the operation type, clarify the operation type used by each part of the part, so as to facilitate the determination of the operation type of the place that needs to be modified in the subsequent process, and filter and search according to the type. For example, the operations of the Pocketing type ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com