Stranded cable outer-diameter control device for superconducting cable conductor for nuclear fusion device and control method

A technology of superconducting cables and control methods, applied in cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of superconducting wire breakage, superconducting strand coating falling off, uneven porosity, etc., to achieve a constant outer diameter Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1 Take PF5 superconducting cable as an example,

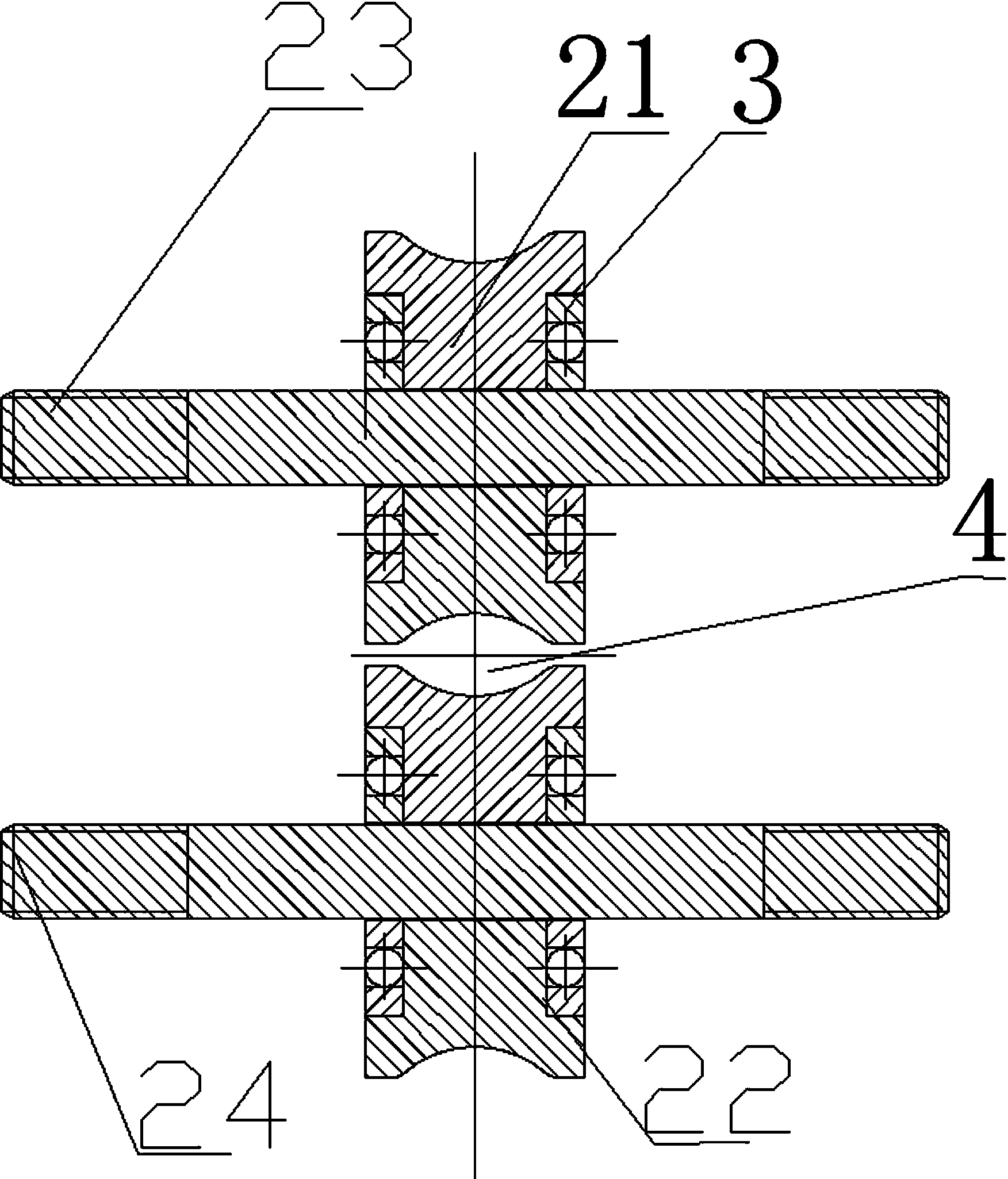

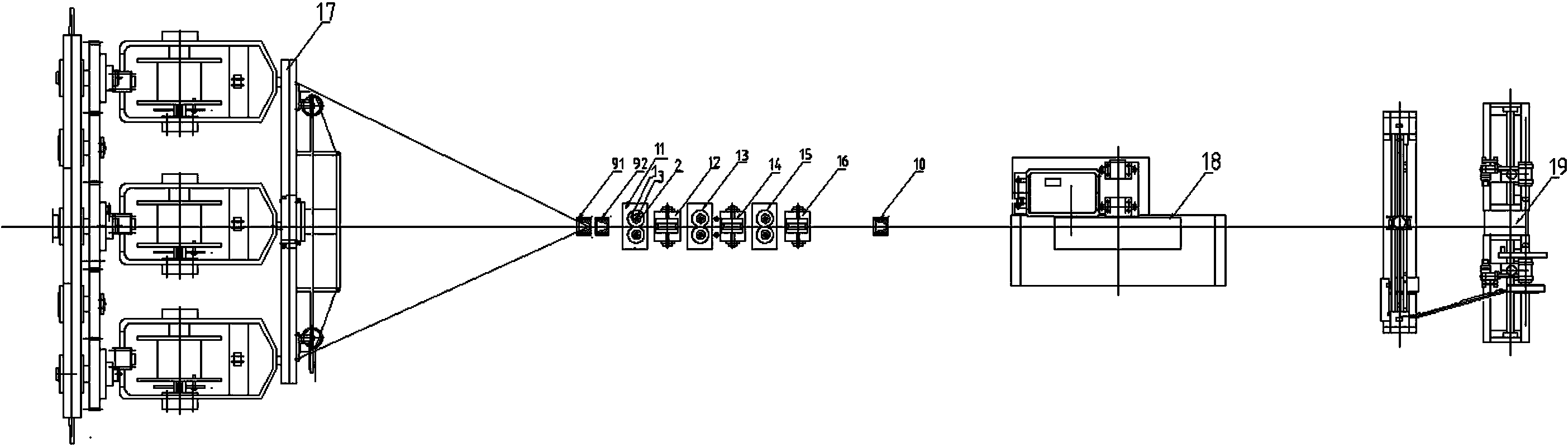

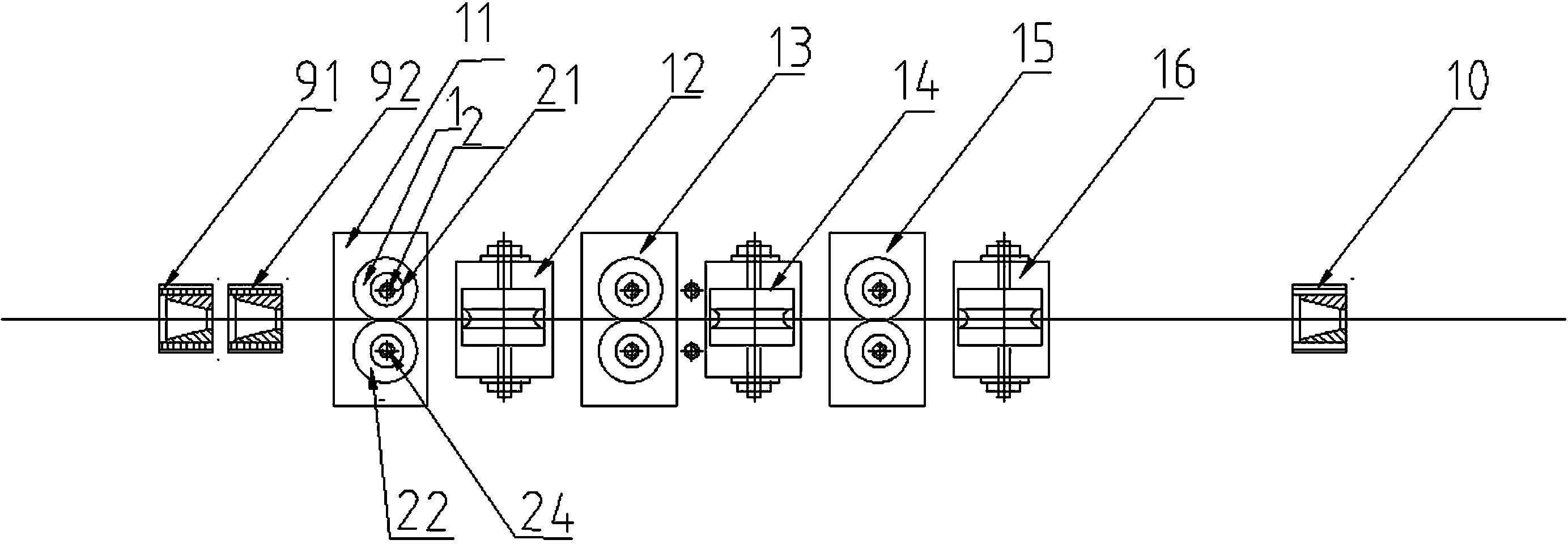

[0033] When the superconducting cable is stranded, the strands first pass from the sheave 17 to the first doubling die 91 with an aperture of 38.5 mm, and then pass through the second doubling die 92 with an aperture of 37.5 mm to be closed. The guide cable enters the first roller roller 11 with an aperture of 36.5 mm, the second roller roller 12 has an aperture of 36.3 mm, the third roller roller 13 has an aperture of 36.0 mm, the fourth roller roller 14 has an aperture of 35.8 mm, and the fifth roller The diameter of the roller 15 is 35.6 mm, and the diameter of the sixth roller 16 is 35.4 mm for rolling, so that the outer diameter of the superconducting cable reaches 35.4±0.4 mm. After six rollers for rolling, the surface of the roller is hardened and polished, so that the surface coating of the cable strand will not fall off or be damaged due to the uneven surface of the roller during rolling. After that, the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com