Multilayer ceramic electronic component

一种电子部件、陶瓷的技术,应用在外部电极的结构领域,达到姿态稳定的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

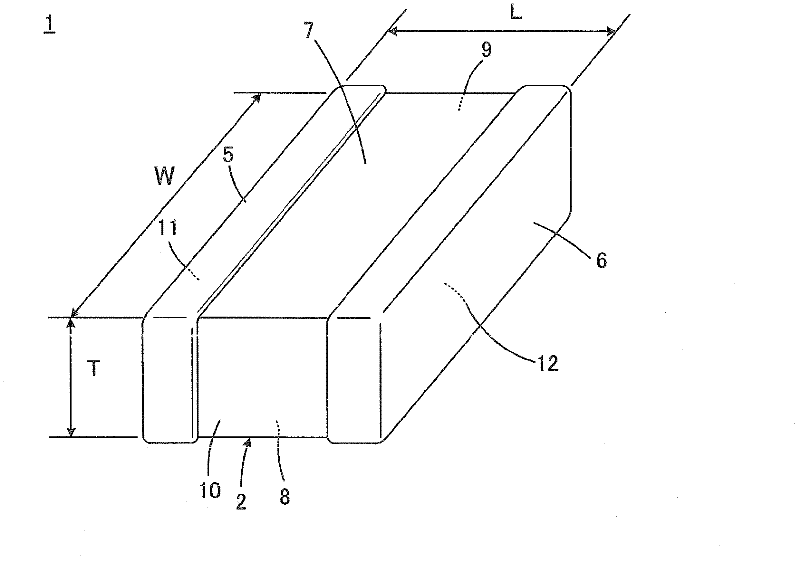

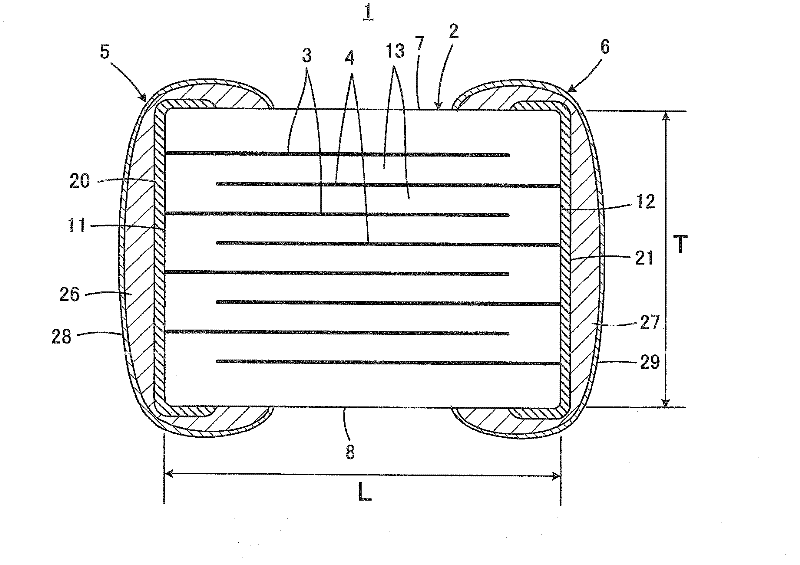

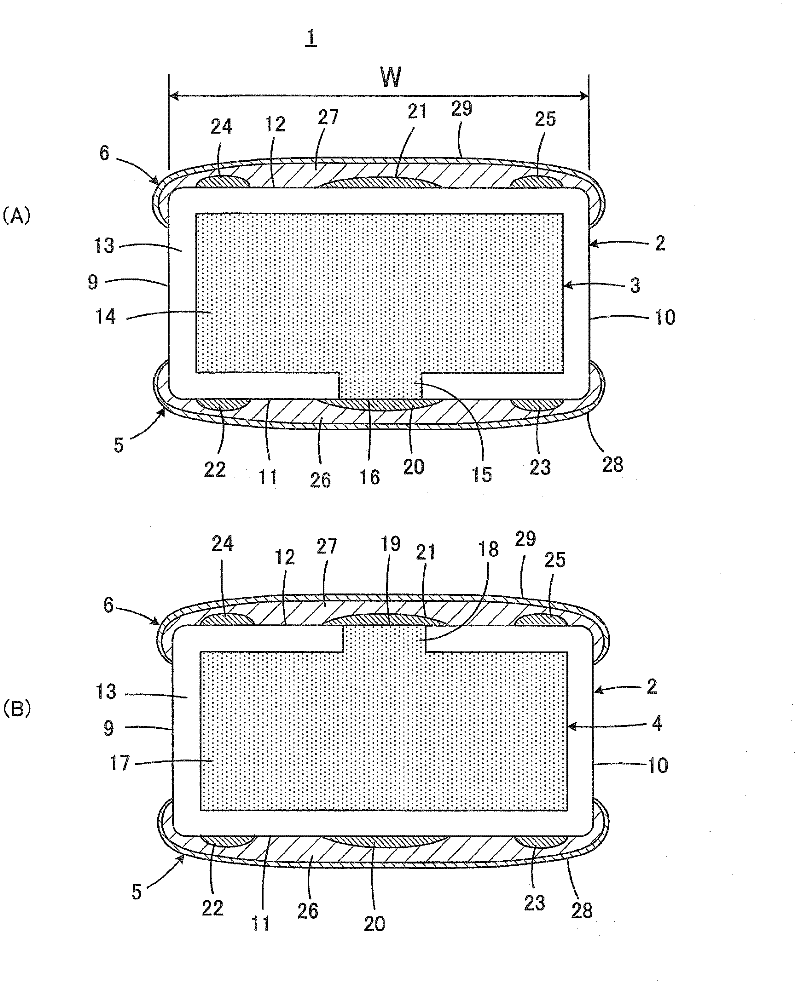

[0067] Figure 1 to Figure 6 It is a figure for demonstrating the 1st Embodiment of this invention. The multilayer ceramic capacitor 1 of the first embodiment is an ESR control type. Multilayer ceramic capacitor 1 includes a ceramic body 2 , internal electrodes 3 and 4 arranged inside ceramic body 2 , and external electrodes 5 and 6 arranged on the outer surface of ceramic body 2 . Hereinafter, the details of the structure of the multilayer ceramic capacitor 1 will be described for (1) the ceramic main body, (2) the internal electrodes, and (3) the external electrodes, and then (4) the manufacturing method will be described.

[0068] (1) Ceramic body

[0069] Such as Figure 1 to Figure 5 As shown, the ceramic main body 2 has a substantially cuboid shape having a pair of opposing main surfaces 7 and 8 , a pair of opposing side surfaces 9 and 10 , and a pair of opposing end surfaces 11 and 12 . Preferably, the ceramic body 2 has rounded corners and edges.

[0070] Such as ...

no. 2 Embodiment approach

[0137] The second embodiment of the present invention is as Figure 7 shown. Figure 7 for with image 3 (B) Corresponding plot. exist Figure 7 in, right with image 3 Components corresponding to the components shown in (B) are given the same reference signs, and overlapping descriptions are omitted.

[0138] exist Figure 7 In the illustrated multilayer ceramic capacitor 1 a , the protrusions 22 a to 25 a are formed so as to be wound not only around the end faces 11 and 12 but at least around the side faces 9 and 10 . Although not shown in the figure, the protrusions 22 a to 25 a may be formed so as to be wound around the main surfaces 7 and 8 .

[0139] According to the above-mentioned structure, although the situation that moisture is more likely to infiltrate into the protrusions 22a to 25a is caused, even if the water infiltrates into the protrusions 22a to 25a, since there are no exposed ends 16 and 4 of the internal electrodes 3 and 4 below them. 19, so no serio...

no. 3 Embodiment approach

[0141] The third embodiment of the present invention is Figure 8 Indicated. Figure 8 for with Figure 4 corresponding figure. Figure 8 in, right with Figure 4 Elements corresponding to the elements shown are assigned the same reference signs, and redundant explanations are omitted.

[0142] exist Figure 8 In the illustrated ceramic body 2 , the first conductive portion 20 b and the protrusions 22 b and 23 b are formed only on the end surface 11 . about the Figure 8 The shown first conductive portion and protrusions on the end surface 12 which is the rear side of the ceramic main body 2 are formed only on the end surface 12, although not shown in the figure.

[0143] According to this configuration, the T direction of the external electrodes can be suppressed (refer to figure 1 as well as figure 2 ) on the thickness, so the thickness of the laminated ceramic electronic components can be reduced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| sintering temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com