Wire clamper of butterfly ceramic bottle of power distribution room

A technology of distribution station area and clamping device, which is applied in the direction of electrical components, switchgear, etc., can solve the problems of poor manufacturing process and low safety level of down conductors, and achieve the effects of strong applicability, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

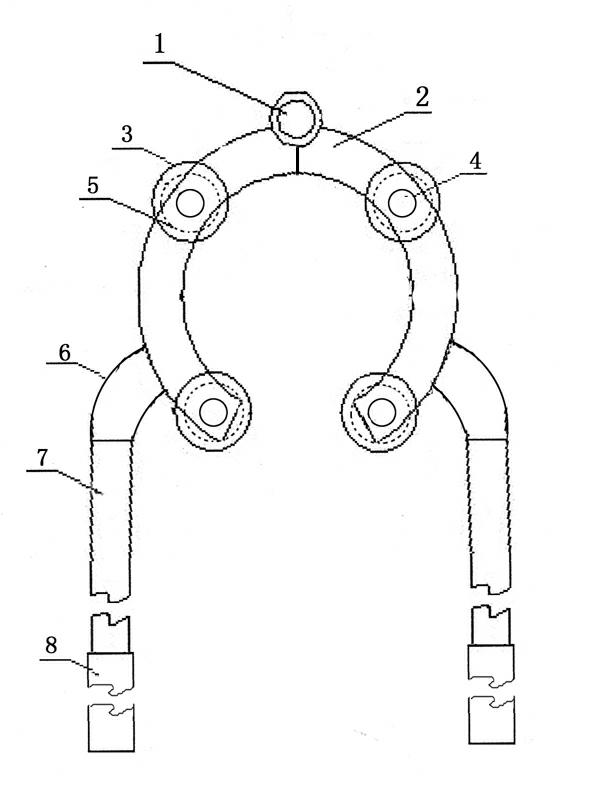

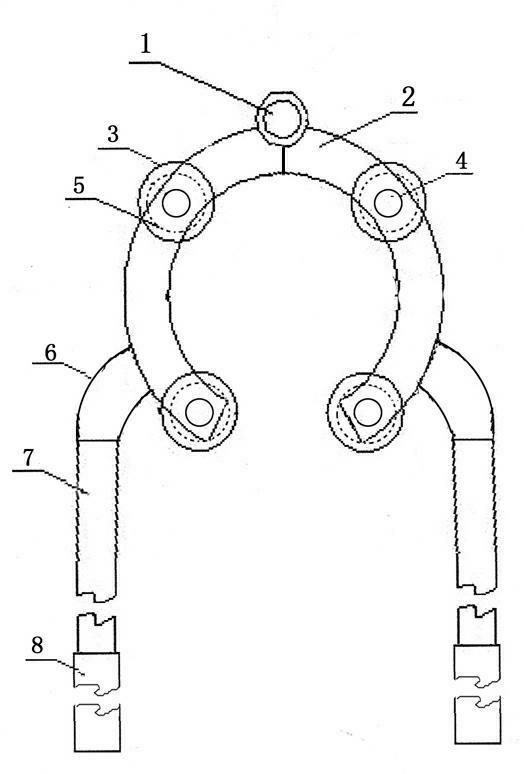

[0008] Implementation Referring to the accompanying drawings, the present invention includes a lever fulcrum rotating tube 1, an arc-shaped lever arm 2, a fixed pulley 3, an extended arm 7 and an insulating handle 8, one end of the arc-shaped lever arm 2 is sheathed on the lever fulcrum rotating tube 1, and the arc-shaped lever Arm 2 other ends are connected with lengthening force arm 7 and insulating handle 8 by elbow 6, set pulley 3 in arc lever arm 2, fixed pulley 3 side circumferences are provided with wire groove 5. The following is a set of relevant data of an embodiment of the present invention. The lever fulcrum rotating tube 1 is an aluminum alloy tube with a middle inner diameter of 20 mm and a thickness of 3 mm. The diameter of the inner and middle holes is 14 mm, the width of the arc arm 2 is 20 mm, the outer diameter of the fixed pulley 3 is 25 mm, the thickness of the aluminum alloy is 3 mm, and the maximum distance between the inner walls of the two arc lever...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com