Conductive elastic wave for loudspeaker

A loudspeaker and elastic wave technology, which is used in the fixing/tightening of sensors, electrical components, and diaphragms, can solve the problems of high cost, affecting the thickness and weight of elastic waves, and complicated production, so as to achieve low production costs and save energy. Effects that connect work and simplify the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

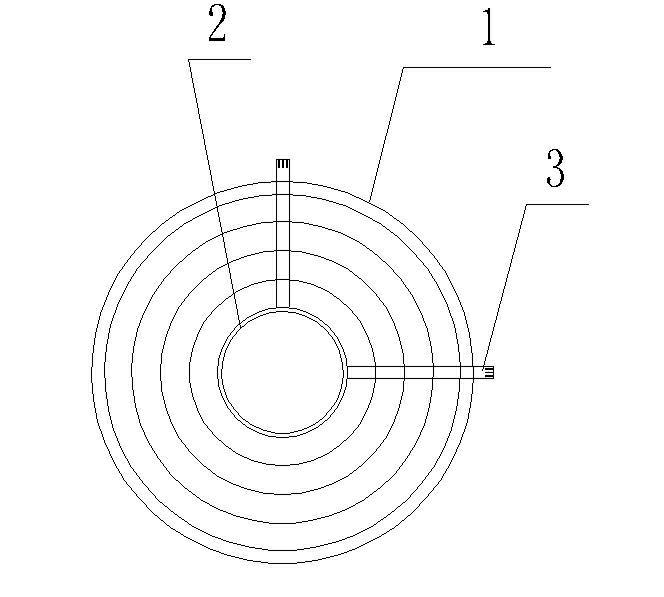

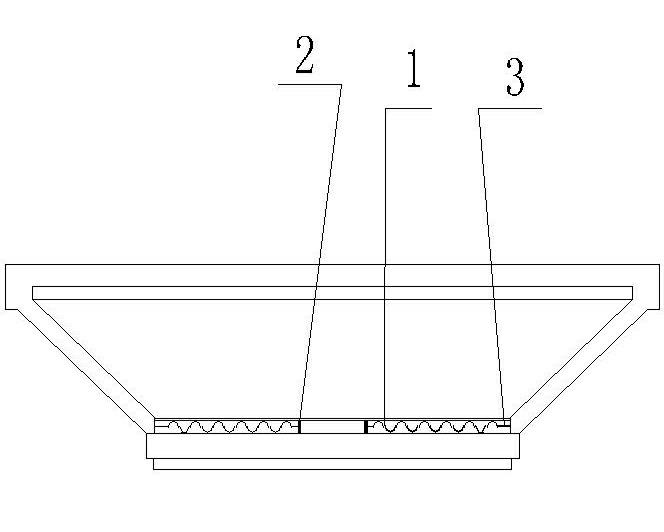

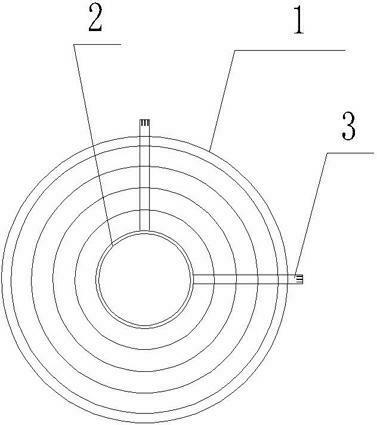

[0015] Such as figure 1 , figure 2 As shown, the loudspeaker of the present invention conducts elastic waves, which are horizontally arranged in the basin frame of the loudspeaker. It is composed of an elastic wave main body 1 corresponding to the central voice coil. There are crests and troughs and a voice coil 2. The surface of the main body of the elastic wave is covered with a strip-shaped FPC board 3 (flexible circuit board). One end of the FPC board 3 is connected to the voice coil, and the other end is provided with a connecting terminal. The outside of the spring body protrudes to connect to the power supply. The FPC board 3 and the elastic wave main body 1 are connected in an integral way by hot pressing. There are two FPC boards 3 arranged vertically on the elastic wave surface, that is, one on the right side and one on the upper side. The rated current of the connecting end of the FPC board is 0.5 ampere or 1 ampere, and conductive coatings arranged at intervals...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com