Dry-point silicon nitride electric heating element and manufacturing method thereof

A silicon nitride electric and heating element technology, applied in the direction of heating element materials, etc., can solve the problems of poor corrosion resistance, low safety and reliability, and short service life, and achieve good wear resistance, excellent wear resistance, Good thermal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

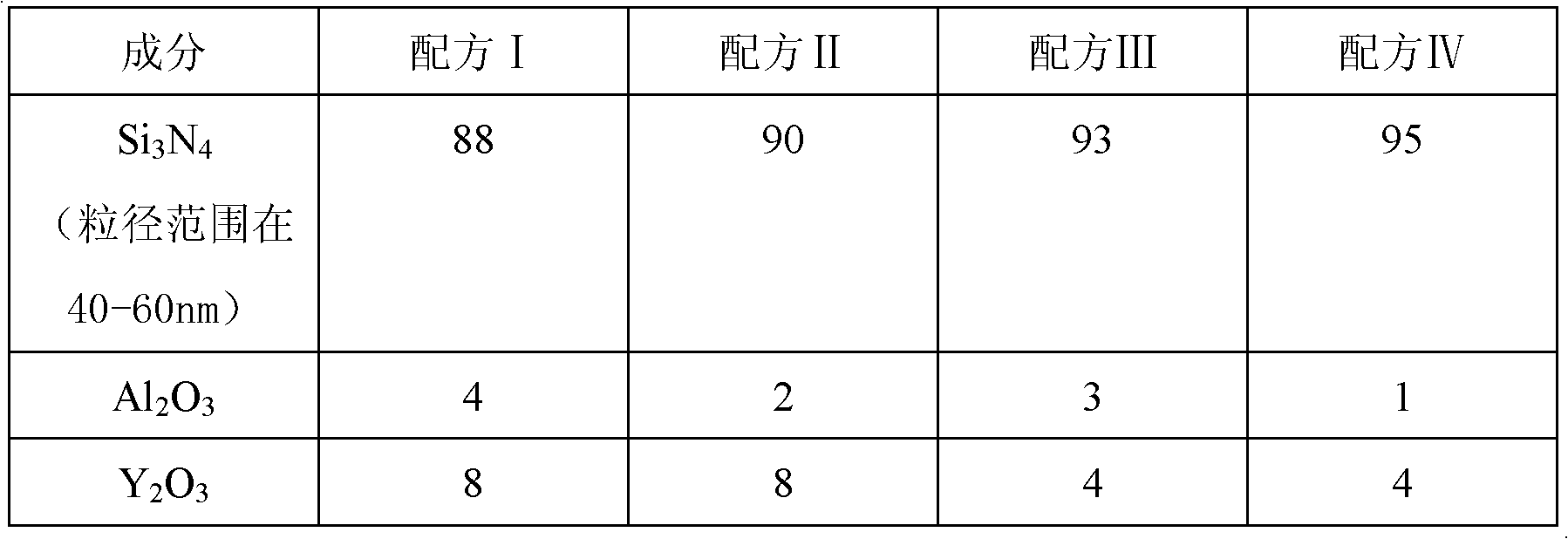

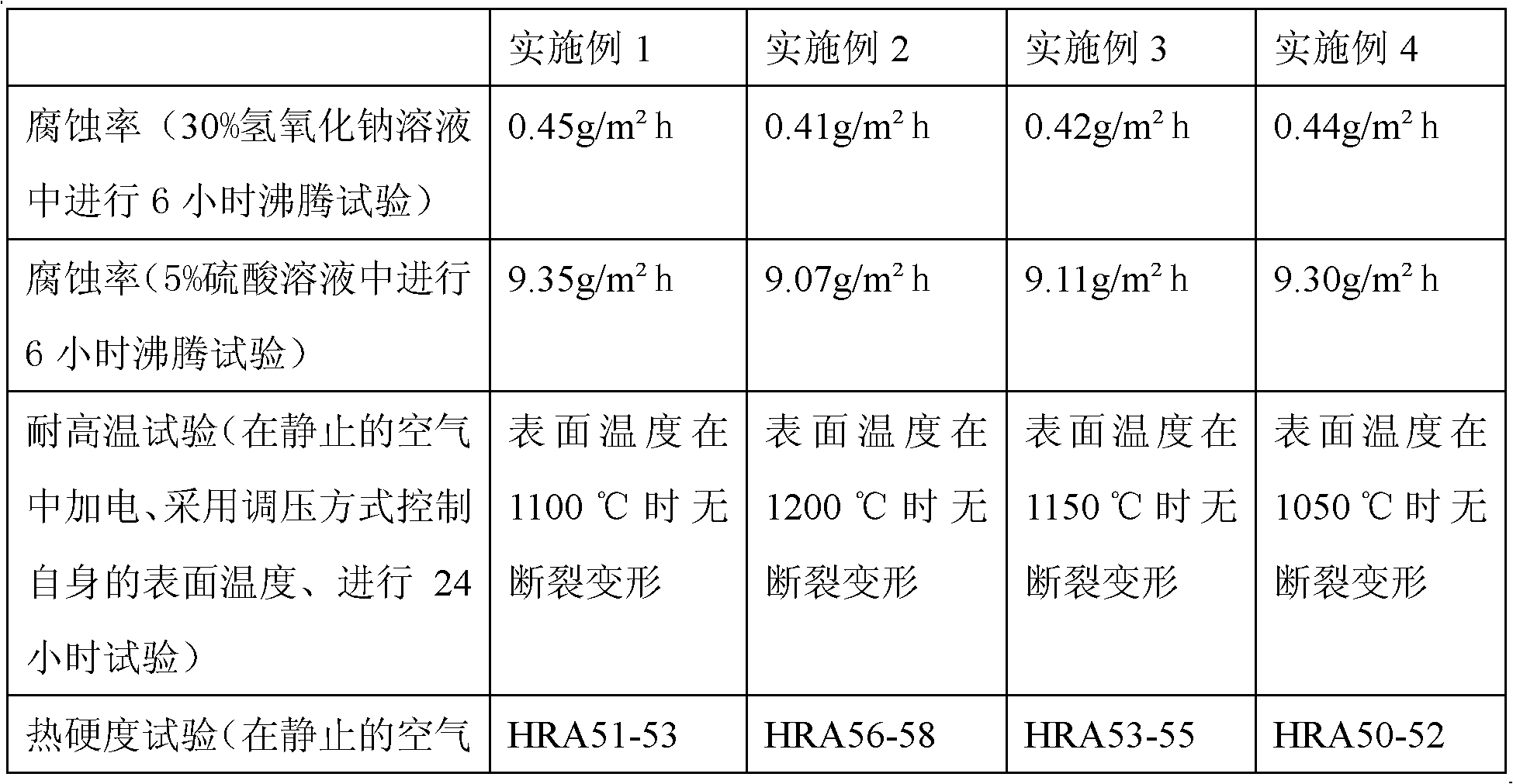

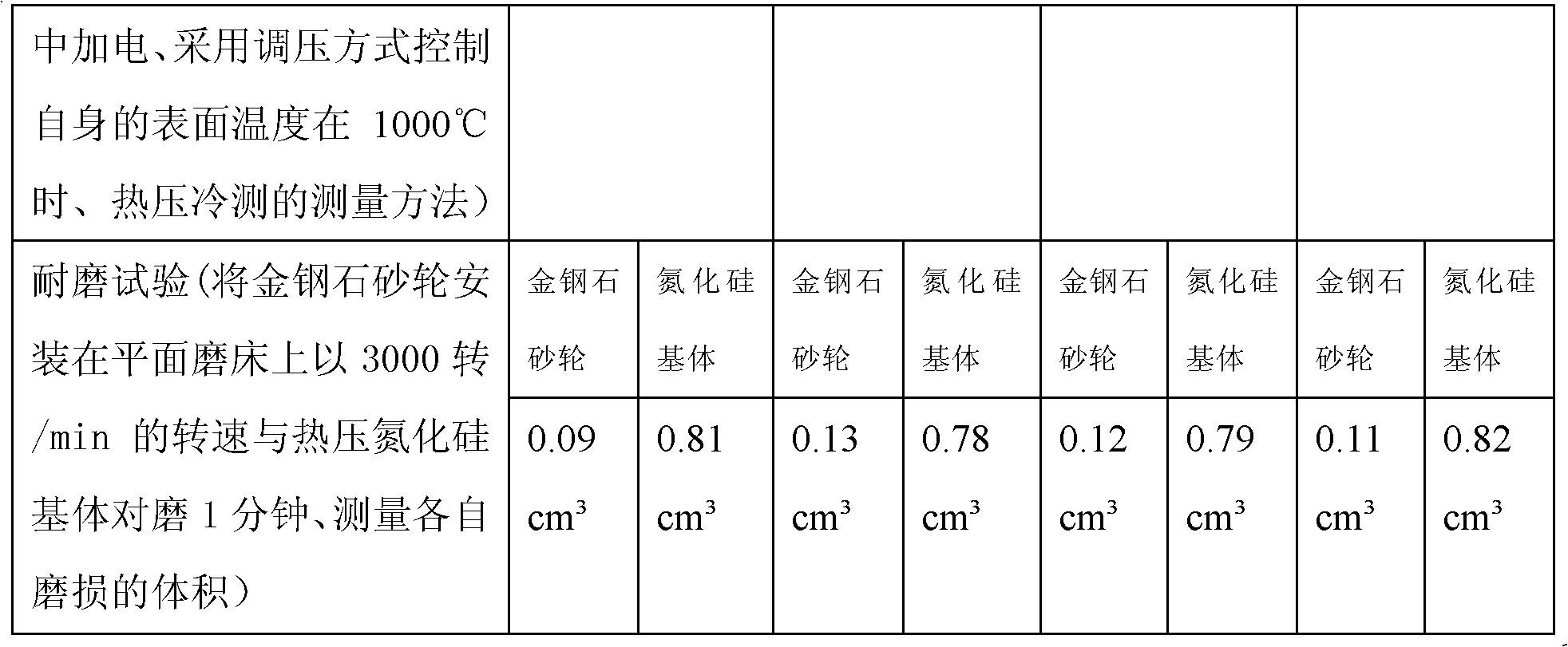

Embodiment 1

[0034] The sintering process of the biscuit prepared by formula I is as follows: heat the graphite mold at room temperature to 1015°C within 35 minutes, continue to heat up and start to pressurize, heat the graphite mold to 1780°C again within 90 minutes, and accelerate at an even speed. Press to 29 砘, (single-layer firing 10 pieces) and keep it for 10 minutes, then cool the graphite mold to 1750°C within 5 minutes, raise it to 1760°C within 5 minutes and keep it for 35 minutes, turn off the machine and let it cool down naturally, and release the pressure.

Embodiment 2

[0036] The sintering process of the biscuit prepared by formula II is as follows: heat the graphite mold at room temperature to 1000°C within 40 minutes, continue to heat up and start to pressurize, heat the graphite mold to 1785°C again within 70 minutes, and accelerate at an even speed. Press to 29 砘, (single-layer firing 10 pieces) and keep it for 8 minutes, then cool the graphite mold to 1680°C within 5 minutes, raise it to 1760°C in 10 minutes and keep it for 40 minutes, turn off the machine and let it cool down naturally, and release the pressure.

Embodiment 3

[0038] The sintering process of the biscuit prepared by formula III is as follows: heat the graphite mold at room temperature to 1015°C within 30 minutes, continue to heat up and start to pressurize, heat the graphite mold to 1750°C again within 85 minutes, and accelerate at an even speed. Press to 29 砘, (single-layer firing 10 pieces) and keep it for 4 minutes, then cool the graphite mold to 1730°C within 5 minutes, raise it to 1760°C in 7 minutes and keep it for 20 minutes, turn off the machine and let it cool down naturally, and release the pressure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com