Method for forming circle food

A food forming and food technology, applied in the field of food forming, can solve the problems of production efficiency and output decline, prone to mechanical failure, complex structure, etc., and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

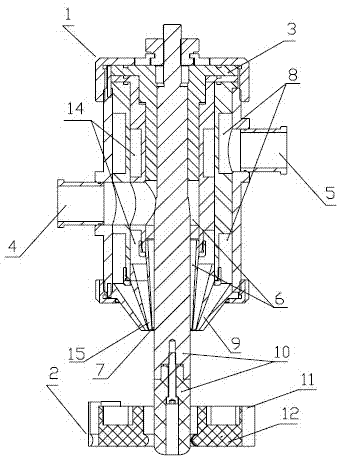

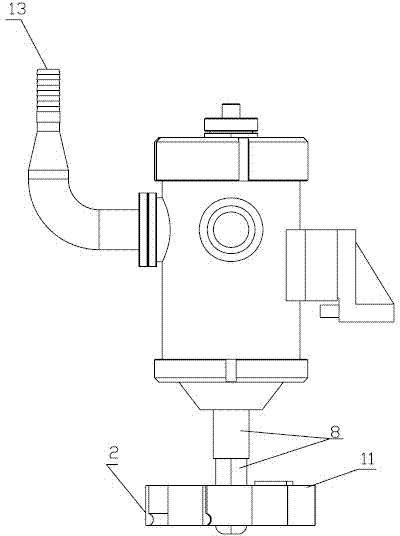

[0026] Ring food forming device includes a compound head and a cutting device, the cutting device is arranged under the compound head, the compound head includes an inner layer material inlet and an outer layer material inlet arranged on the body, and the inner layer material inlet passes through the inner material inlet in the compound head body. The layer material channel communicates with the inner layer material outlet at the bottom of the compound head body; the outer layer material inlet communicates with the outer layer material outlet at the bottom of the compound head body through the outer layer material channel in the compound head body.

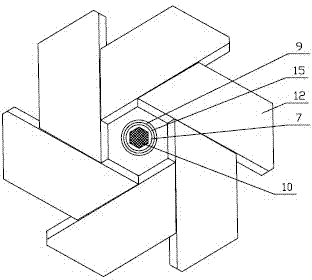

[0027] Both the material outlet of the inner layer and the material outlet of the outer layer are ring-shaped, and the material outlet of the inner layer is located inside the material outlet of the outer layer. The compound head body is provided with multi-square rods, and the multi-square rods pass through the bottom of the compo...

Embodiment 2

[0030] Ring food forming device includes a compound head and a cutting device, the cutting device is arranged under the compound head, the compound head includes an inner layer material inlet and an outer layer material inlet arranged on the body, and the inner layer material inlet passes through the inner material inlet in the compound head body. The layer material channel is connected with the inner layer material outlet at the bottom of the composite head body; the outer layer material inlet is connected with the outer layer material outlet at the bottom of the compound head body through the outer layer material channel in the compound head body; the inner layer material outlet is connected with the outer layer material outlet. The outlets are all ring-shaped, and the inner layer material outlet is located inside the outer layer material outlet; the compound head body is also provided with a middle layer material inlet, and the middle layer material inlet passes through the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com