Coiler for trimmings of cold-rolling strip steel

A technology of cold-rolled strip steel and edge coiling, applied in metal rolling, metal rolling, manufacturing tools, etc., can solve the problems of complex structure of guiding mechanism, complex structure of recovery device, increase of manufacturing cost and difficulty of recovery device, etc. Achieve the effect of convenient use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

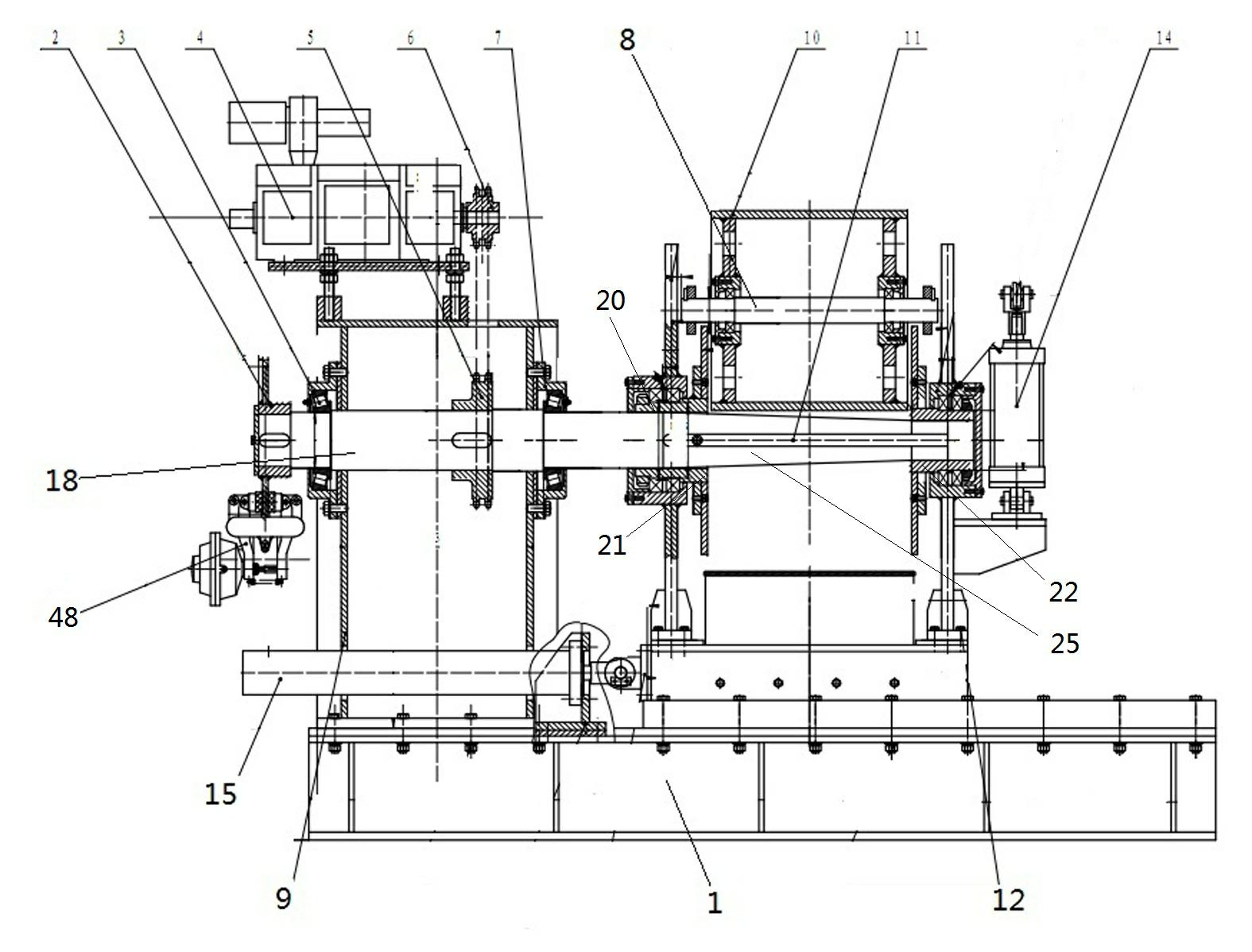

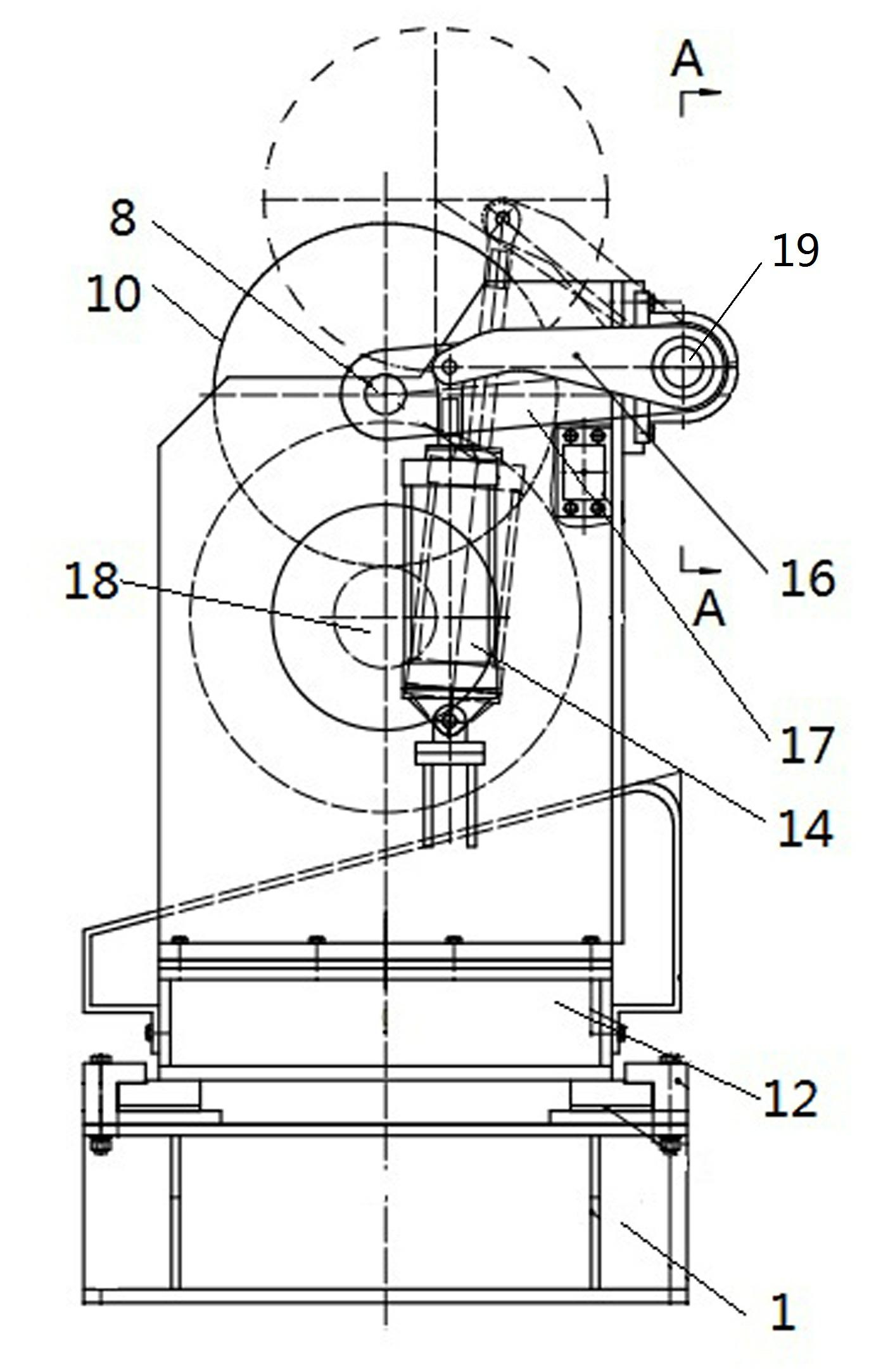

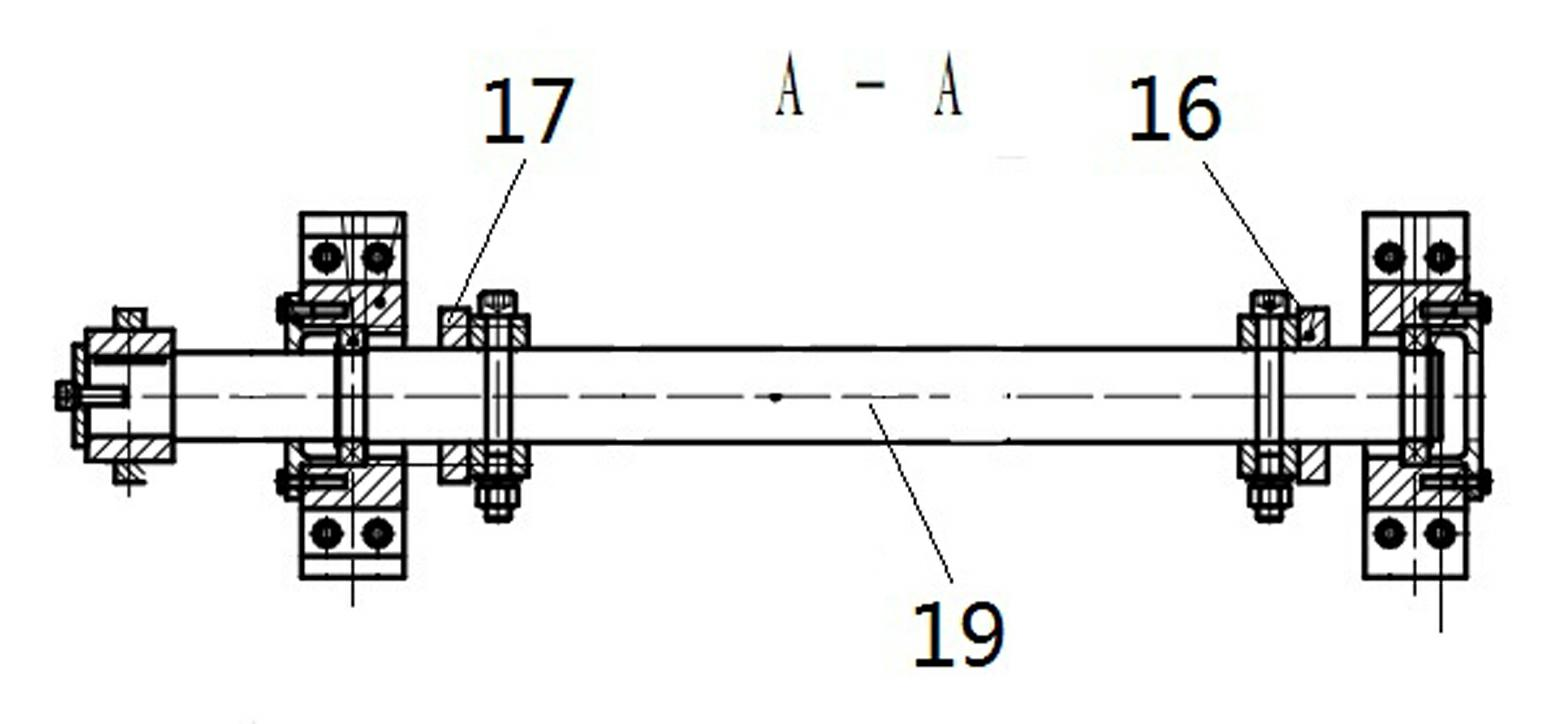

[0022] Examples of cold-rolled strip scrap coiler Figure 1~3 Shown: It includes a frame composed of a workbench 1, a fixed frame 12 and a movable frame 9. The fixed frame 12 is fixed on the workbench 1. The workbench 1 is provided with slide rails extending forward and backward in the guiding direction, and the movable frame 9 guides Sliding assembly and slide rail, between the movable frame 9 and the fixed frame 12, there is a loading oil cylinder 15 that is connected with the movable frame 9 and drives the movable frame 9 to reciprocate slide along the slide rail, and one end of the loading oil cylinder 15 is hingedly connected with the movable frame 9 , and the other end is hingedly connected with the fixed frame 12. The rotation of the axial limit on the movable frame 9 is equipped with a reclaiming shaft 18 whose axis of rotation extends along the front-to-back direction. The input section, the movable frame 9 is also provided with the drive motor 4 that is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com