Biserial chain quadrangular riveting machine

A technology of riveting presses and chains, applied in the direction of metal chains, etc., can solve the problems of large shock and vibration, affecting the service life of the machine, hidden safety hazards, etc., and achieve the effects of prolonging the service life, maintaining profits and safety, and reducing the downtime rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

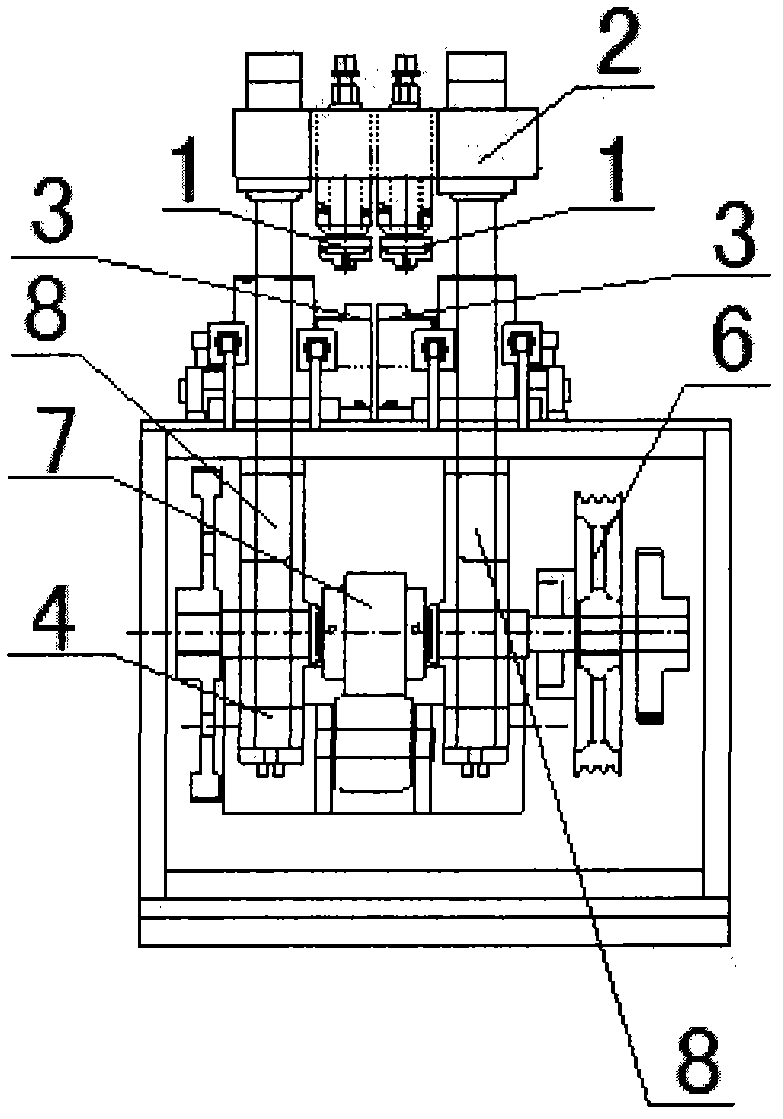

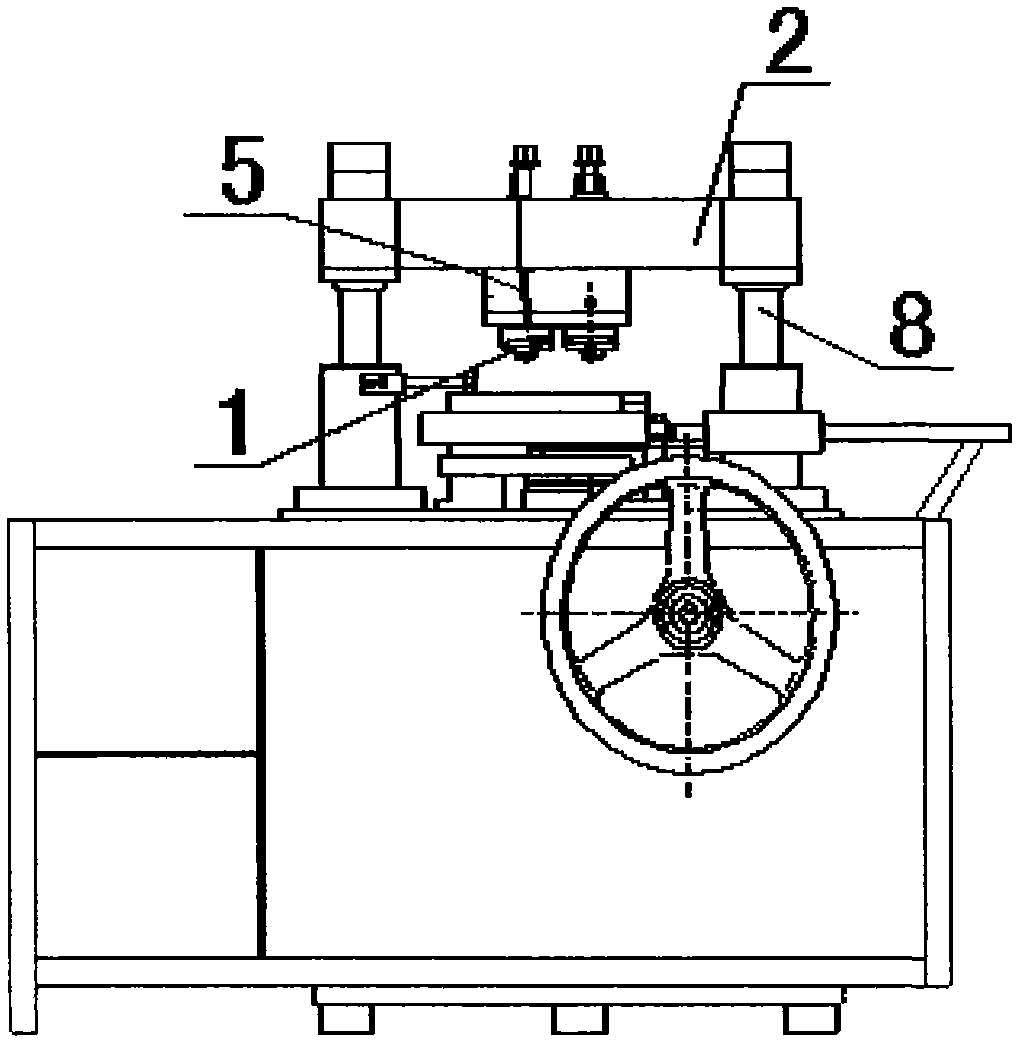

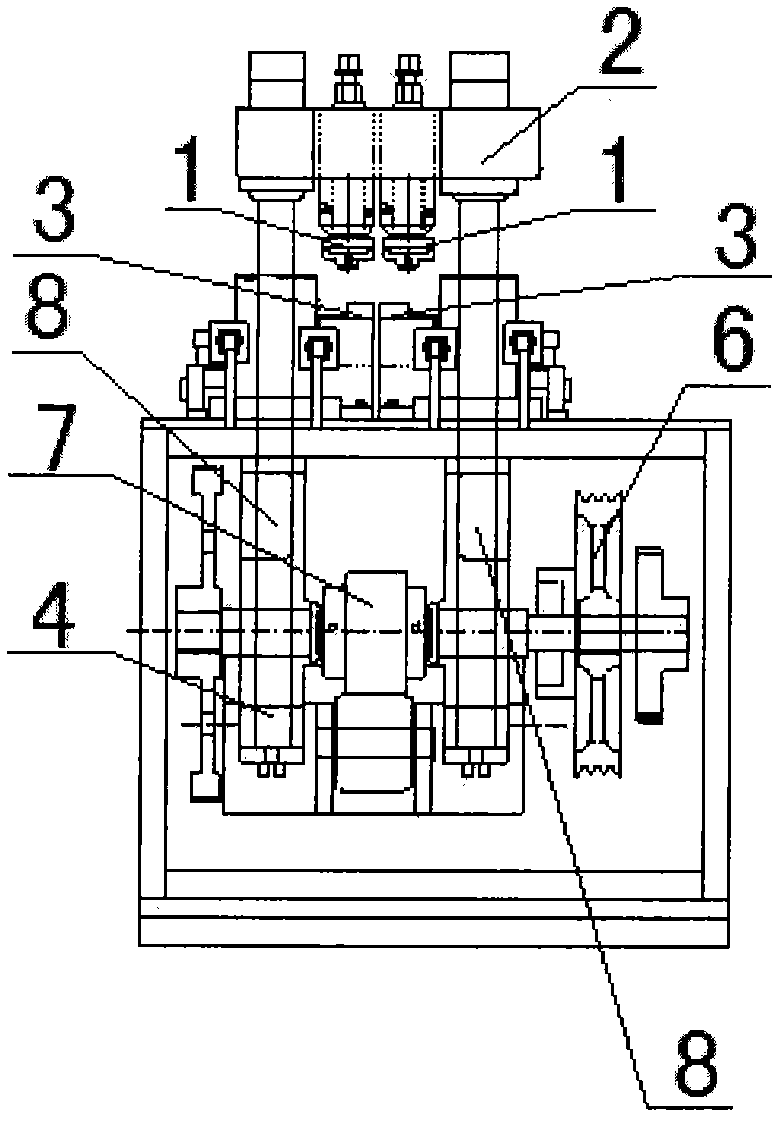

[0012] refer to Figure 1-Figure 2 , the double-row chain four-corner riveting press of the present embodiment includes a power unit, a supporting device, a stamping die, and a safety protection device. The riveting chain is placed in the stamping die, and the power unit is arranged under the working platform of the riveting press. The device cooperates with the stamping die by connecting the supporting device, and the supporting device is provided with a safety protection device 5 for its protection. Described power unit comprises motor, big pulley 6, camshaft 7, and the output end of motor is connected with big pulley 6, camshaft 7 by shaft. The support device includes an upper beam 2, a lower beam 4, and a column 8. The top of the column 8 is connected with the upper beam 2, and the bottom end thereof is connected with the lower beam 4. The safety protection device 5 is arranged on the upper beam 2. The stamping dies are arranged side by side in pairs, and the stamping die...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com