Kindle direct publishing (KDP) crystal micro-nano hygroscopic ultraprecision polishing method based on ultrasonic atomization moisture

An ultrasonic atomization and ultra-precision technology, applied in the field of ultra-precision polishing, can solve the problems of secondary damage on the surface of the processed crystal, and achieve the processing requirements of avoiding secondary deliquescence, avoiding secondary damage and ensuring high surface accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

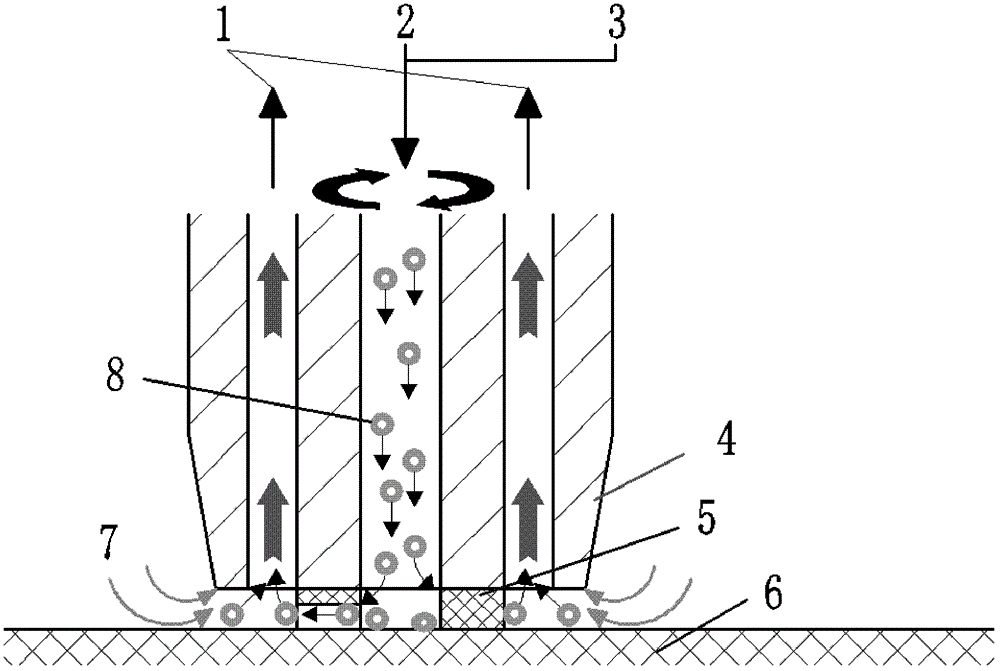

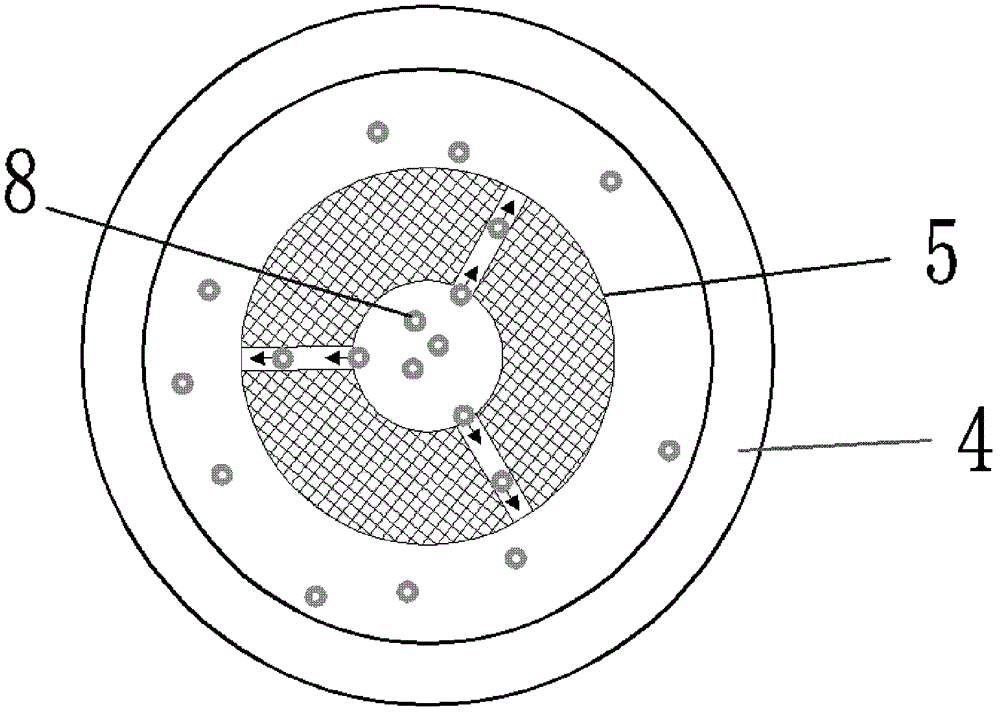

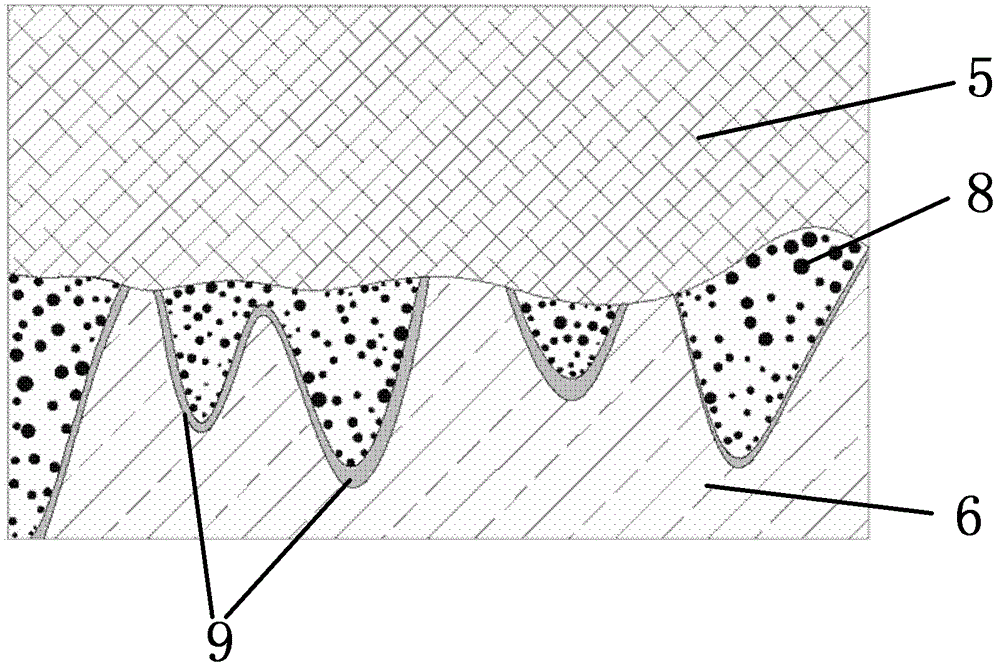

[0027]Example: The clean and dry gas 2 of the compressed air source is filtered through a precision filter with a filtration accuracy of 0.01 μm, free of impurities and dust; the ultrasonic water mist generator has an ultrasonic oscillation frequency of 2.4 MHz, and generates water mist 3, which is fully mixed with the clean air source The relative humidity of the mixed gas is detected by a hygrometer, and its relative humidity is controlled by adjusting the flow rate of clean gas and the amount of water mist generated; the relative humidity of the gas after mixing is controlled at 90%, and the flow rate is 10L / min; the polishing head 4 is pressed on the polished KDP crystal 6 on the surface; the mixed clean moist gas passes through the central hole on the polishing pad 5, and the liquid droplets 8 in the moist gas contact the polished crystal; the part of the crystal surface that is in contact with the moist gas undergoes micro deliquescence and forms on the crystal surface On...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com