Clamp and clamping method for large-diameter plane optical element

An optical element, large-diameter technology, used in optical surface grinders, manufacturing tools, grinding/polishing equipment, etc., to solve problems such as optical element damage or damage growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

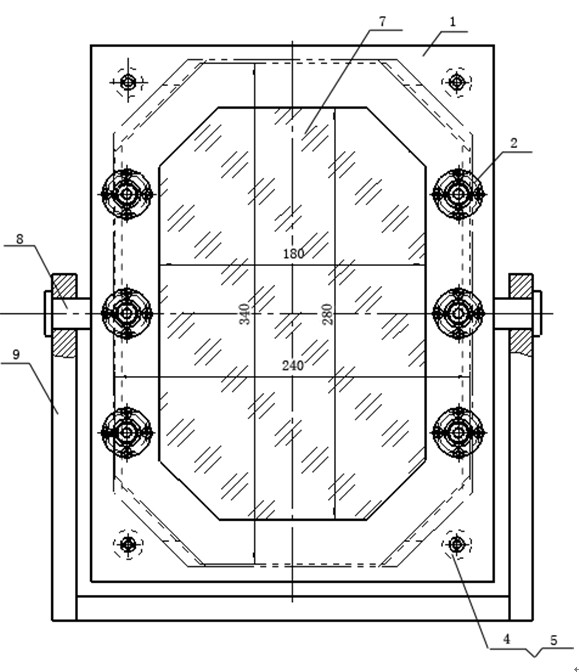

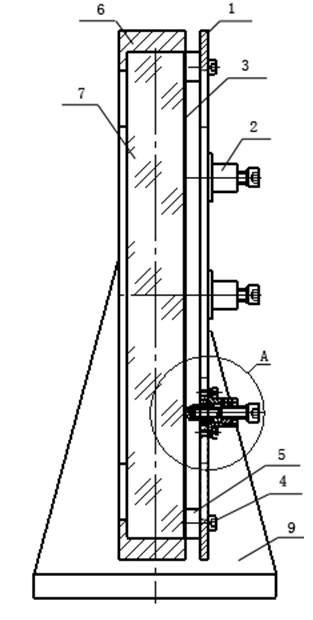

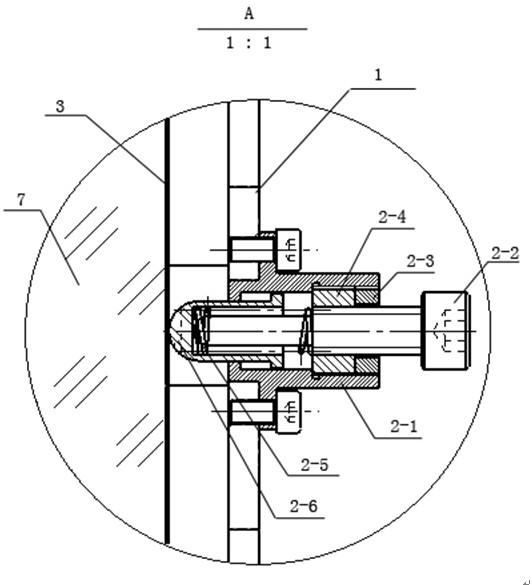

[0041] see first figure 1 , figure 1 It is a front view of the structure of the clamp for the large-diameter planar optical element of the present invention. It can be seen from the figure that the clamp for the large-diameter planar optical element of the present invention comprises a large-diameter planar optical element pressing plate 1, an elastic fulcrum 2, a deformed thin plate frame 3, an inner Hexagonal cylinder head screw 4, boss 5, picture frame 6, rotating shaft 8 and support 9, the positional relationship of above-mentioned elements is as follows:

[0042] The clamped large-diameter planar optical element 7 should leave a certain periphery outside the clear aperture for the described deformed thin plate frame 3 to be pasted. The shape of the perimeter is the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com