Transmission mechanism of toilet paper packing machine

A technology of transmission mechanism and packaging machine, which is applied in the field of papermaking machinery and can solve problems such as restricting the production line capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

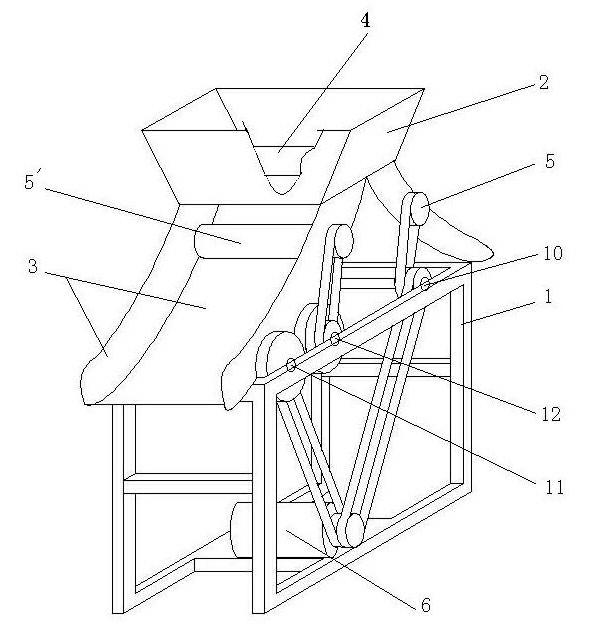

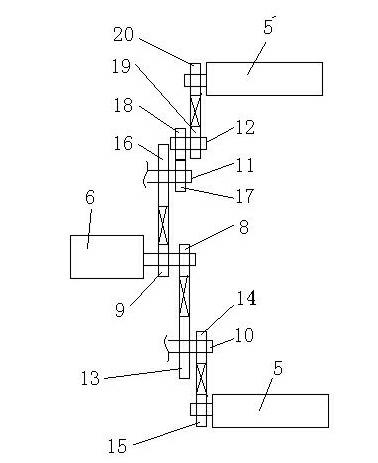

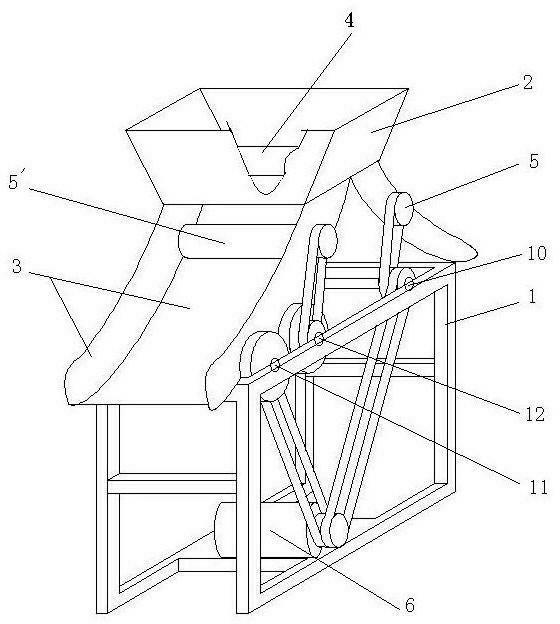

[0014] Such as figure 1 Shown, the present invention comprises frame 1, is arranged on the receiving hopper 2 on the frame 1, the feeding chute 3, the top of described feeding chute 3 is communicated with the feeding port of receiving hopper 2, and the bottom of the feeding port The lower sides extend in an arc;

[0015] It also includes the distribution roller 4 that is movably connected to the middle part of the lower material opening of the receiving hopper 2, and the feeding roller I5 and the feeding roller II5' that are rotatably connected to the feeding trough 3, and the feeding roller I5 and the feeding roller II5' are equipped with power devices 6.

[0016] The feeding rollers are arranged perpendicular to the feeding chute 3, and the distribution rollers 4 are arranged parallel to the feeding rollers. The line connecting the center of the same end of the distributing roller 4 and the feeding rollers 5, 5' in the feeding trough 3 on both sides below is in an isoscel...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap