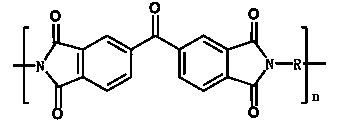

Polyimide and preparation process thereof

A technology of polyimide and mixture, which is applied in the field of chemical polymer material preparation, can solve the problems of time-consuming and energy consumption, and achieve the effects of improving production efficiency, considerable economic value, and shortening the dropping time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

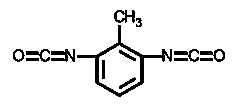

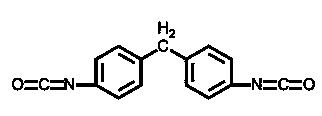

[0031] Add 80.5 g of benzophenone tetracarboxylic dianhydride (BTDI) to 250 ml of N,N'-dimethylformamide (DMF), add 0.075 g of NaOH, and dissolve in 0.2 ml of water. Mechanical stirring, nitrogen protection, heating at 80 °C to dissolve, after dissolution, add two diisocyanates at one time - a mixture of 4,4`-diphenylmethane diisocyanate (MDI) and toluene diisocyanate (TDI) (The molar ratio of TDI to MDI was 4:1) 37.88 g, reacted for 1 hour, and the temperature was controlled at 80°C. Next, 9.47 g of the diisocyanate mixture was added dropwise to the reaction system for 1 hour, and the temperature was controlled at 80°C. The reaction was carried out for 1 hour after the completion of the dropwise addition. The mixture was poured into acetone to wash off the solvent. The reduced viscosity test result is about 0.8 (NMP is the solvent, C=0.005g / ml).

Embodiment 2

[0033] 161g of benzophenone tetraacid dianhydride (BTDI) was added to 500ml of N,N'-dimethylacetamide (DMAc), 0.15g of NaOH was added, and dissolved in 0.4ml of water. Mechanical stirring, nitrogen protection, heating at 120 ° C to dissolve, after dissolution, two diisocyanates - 4,4`-diphenylmethane diisocyanate (MDI) and toluene diisocyanate (TDI) mixture ( The molar ratio of TDI to MDI was 4:1) 66.29 g, the reaction was performed for 45 minutes, and the temperature was controlled at 120 °C. 28.41 g of the diisocyanate mixture was added dropwise to the reaction system, the dropwise addition time was 1 hour, and the temperature was controlled at 120°C. The reaction was carried out for 2 hours after the completion of the dropwise addition. After the reaction was stopped, the mixture was poured into acetone to wash off the solvent. The reduced viscosity test result is about 0.8 (NMP is the solvent, C=0.005g / ml).

Embodiment 3

[0035] 322g of benzophenone tetraacid dianhydride (BTDI) was added to 500ml of N,N'-dimethylacetamide (DMAc), 0.3g of NaOH was added, and dissolved in 0.8ml of water. Mechanical stirring, nitrogen protection, heating at 60 °C to dissolve, after dissolution, two diisocyanates - 4,4`-diphenylmethane diisocyanate (MDI) and toluene diisocyanate (TDI) mixture ( The molar ratio of TDI to MDI was 4:1) 151.52 g, the reaction was performed for 1 hour, and the temperature was controlled at 60 °C. 37.88 g of the diisocyanate mixture was added dropwise to the reaction system, the dropwise addition time was 1 hour, and the temperature was controlled at 60°C. The reaction was carried out for 1.5 hours after the completion of the dropwise addition. After the reaction was stopped, the mixture was poured into acetone to wash off the solvent. The reduced viscosity test result is about 0.8 (NMP is the solvent, C=0.005g / ml).

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com