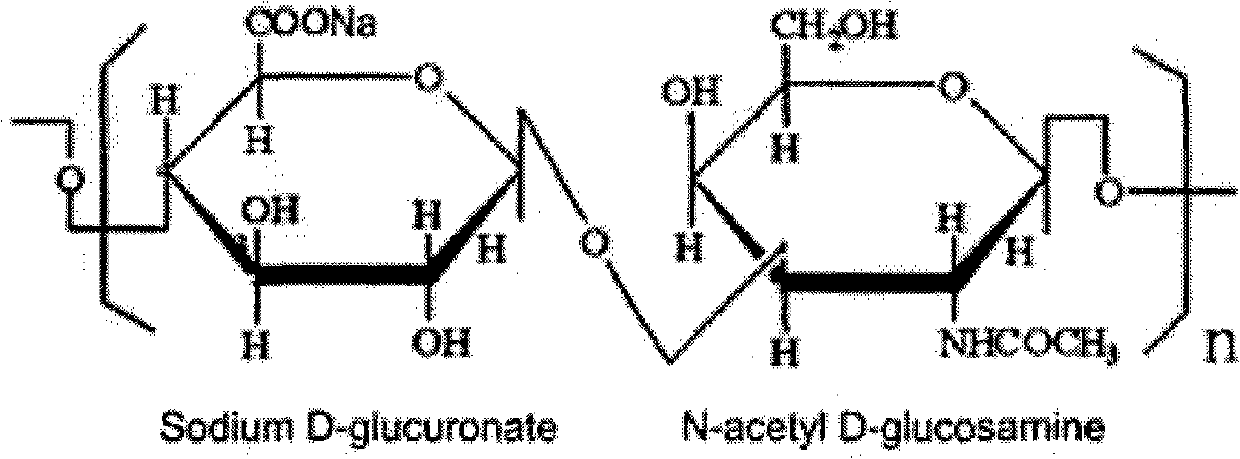

Method for preparing powdered sodium hyaluronate

A sodium hyaluronate, powdery technology, applied in the field of preparation of sodium hyaluronate, can solve the problems of increasing the risk of bacterial contamination of sterile sodium hyaluronate raw materials, time-consuming dripping, relatively high requirements, etc., to reduce Risk of bacterial contamination with sodium hyaluronate, shortening of dropping time, and effects of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

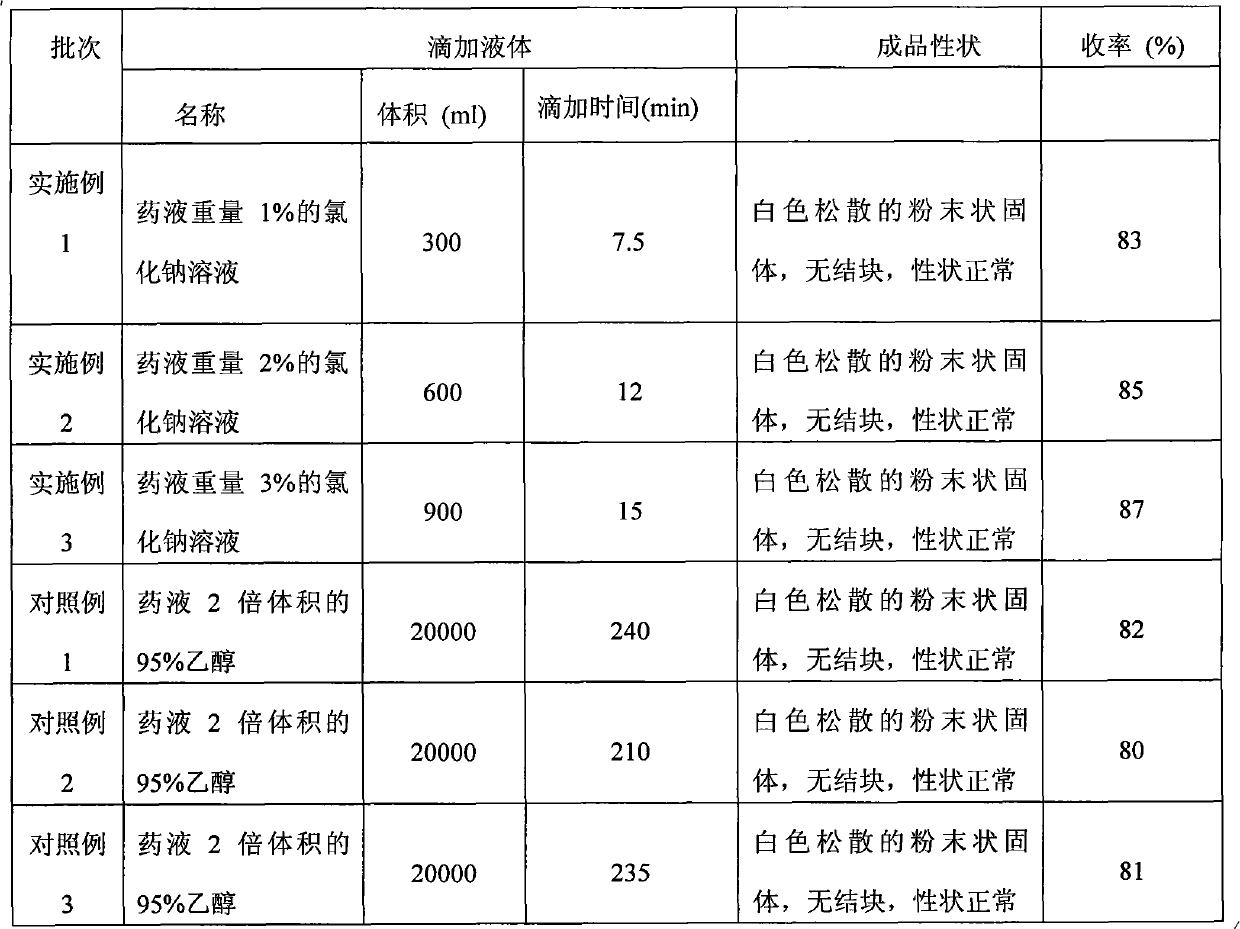

Embodiment 1

[0031] In the final alcohol precipitation step of sodium hyaluronate prepared by the cockscomb extraction method, 50 grams of the intermediate sodium hyaluronate prepared in the previous process was added into 10 L of water, stirred and dissolved to obtain a sodium hyaluronate solution. Take 20L of 95% ethanol, add it into the sodium hyaluronate solution under stirring state and mix well. Take 100 grams of sodium chloride and add 300 milliliters of water to dissolve it, and slowly add it dropwise to the above mixed solution at a speed of 40 ml / min. During this process, constant stirring is required. After the powdered sodium hyaluronate is alcohol-precipitated, extract it into a filter washing and drying machine. After filtering the mother liquor, add about 10L of 95% ethanol to stir and dehydrate it for 5 minutes, and repeat this three times. After the dehydration is completed, the powder is sucked dry, and dried under a vacuum pressure of 0.08MPa and a temperature of about 4...

Embodiment 2

[0033] In the final alcohol precipitation step of the sodium hyaluronate purification production process prepared by bacterial fermentation, 50 grams of the sodium hyaluronate intermediate product prepared in the previous process was added to 10 L of water, stirred and dissolved to obtain a sodium hyaluronate solution. Take 20L of 95% ethanol, add it into the sodium hyaluronate solution under stirring state and mix well. Take 200 grams of sodium chloride and add 600 milliliters of water to dissolve it, then slowly add it dropwise to the above mixed solution at a speed of 50 ml / min, and continuous stirring is required during this process. After the powdered sodium hyaluronate is alcohol-precipitated, extract it into a filter washing and drying machine. After filtering the mother liquor, add about 10L of 95% ethanol to stir and dehydrate it for 5 minutes, and repeat this three times. After the dehydration is completed, the powder is sucked dry, and dried under a vacuum pressure ...

Embodiment 3

[0035] In the final alcohol precipitation step of sodium hyaluronate prepared by the cockscomb extraction method, 50 grams of the intermediate sodium hyaluronate prepared in the previous process was added into 10 L of water, stirred and dissolved to obtain a sodium hyaluronate solution. Take 20L of 95% ethanol, add it into the sodium hyaluronate solution under stirring state and mix well. After taking 300 grams of sodium chloride and adding 900 milliliters of water to dissolve, slowly add it dropwise to the above mixed solution at a speed of 60 ml / min, and continuous stirring is required during this process. After the powdered sodium hyaluronate is alcohol-precipitated, extract it into a filter washing and drying machine. After filtering the mother liquor, add about 10L of 95% ethanol to stir and dehydrate it for 5 minutes, and repeat this three times. After the dehydration is completed, the powder is sucked dry, and dried under a vacuum pressure of 0.08MPa and a temperature o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com