Synthesizing method for 2-tricarbonyl(methylcyclopentadienyl)manganese

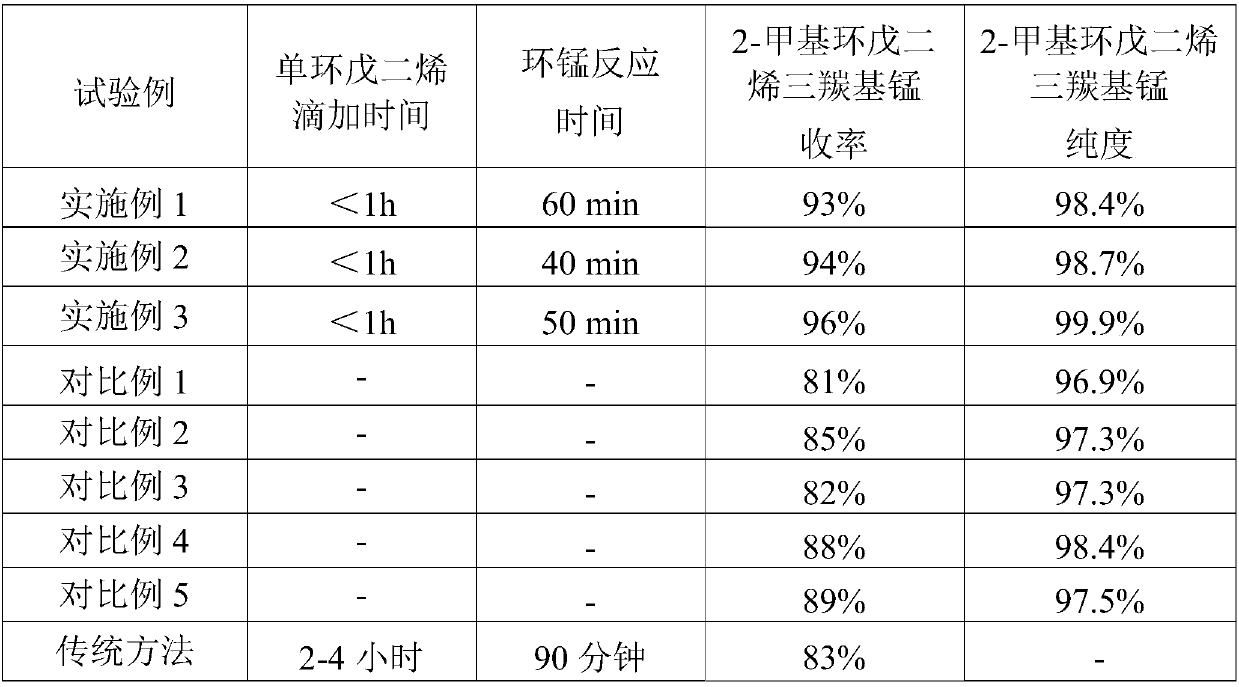

A kind of methylcyclopentadiene manganese tricarbonyl, synthetic method technology, applied in chemical instruments and methods, organic chemistry, metallocene and other directions, can solve the problems of limiting MMT production efficiency, low yield, long time consumption, etc. The effect of shortening the dropping time, improving the yield and purity, and shortening the reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A kind of synthetic method of 2-methylcyclopentadiene manganese tricarbonyl, comprises the following steps:

[0028] S1, cyclosodium reaction:

[0029] Use white oil to soak the metal sodium wire for 3-5 minutes; prepare a sodium ring kettle, add metal sodium wire to the sodium ring kettle, and then add an organic solvent, the organic solvent is made of tetrahydrofuran and dichloromethane with a volume ratio of 1:1.2 to 3.5 obtained, temperature controlled to 0-15°C for dehydration;

[0030] Then add an auxiliary agent of 0.5-1 times the mass of metal sodium wire to the ring sodium kettle, the auxiliary agent is made of zinc oxide powder, nano silicon dioxide and dry ice in a mass ratio of 10:4-7:3-5, the preferred mass The ratio is 10:5:4.

[0031] Then add monocyclopentadiene dropwise, the molar ratio of the metal sodium wire to monocyclopentadiene is 1:0.9-1.2, and the dropwise addition is completed within 1h, and the reaction temperature is controlled to be 45-53°...

Embodiment 1

[0038] A kind of synthetic method of 2-methylcyclopentadiene manganese tricarbonyl, comprises the following steps:

[0039] S1, cyclosodium reaction:

[0040] Use white oil to soak the metal sodium wire for 3 minutes; prepare a sodium ring kettle, add metal sodium wire to the sodium ring kettle, and then add an organic solvent. The organic solvent is made of tetrahydrofuran and dichloromethane with a volume ratio of 1:1.2, and the temperature is controlled. To 0-15 ℃ for dehydration treatment;

[0041] Then add an auxiliary agent of 0.5 times the mass of the metal sodium wire to the ring sodium kettle, and the auxiliary agent is made of zinc oxide powder, nano silicon dioxide and dry ice in a mass ratio of 10:4:3;

[0042] Then add monocyclopentadiene dropwise, the molar ratio of the metal sodium wire to monocyclopentadiene is 1:0.9, and the dropwise addition is completed within 1 hour, and the reaction temperature is controlled to be about 45°C after the dripping to obtain c...

Embodiment 2

[0049] A kind of synthetic method of 2-methylcyclopentadiene manganese tricarbonyl, comprises the following steps:

[0050] S1, cyclosodium reaction:

[0051] Use white oil to soak the metal sodium wire for 5 minutes; prepare a sodium ring kettle, add metal sodium wire to the sodium ring kettle, and then add an organic solvent. The organic solvent is made of tetrahydrofuran and dichloromethane with a volume ratio of 1:3.5, and the temperature is controlled. To 0-15 ℃ for dehydration treatment;

[0052] Then add an auxiliary agent of 1 times the mass of metal sodium wire to the ring sodium kettle, and the auxiliary agent is made of zinc oxide powder, nano silicon dioxide and dry ice in a mass ratio of 10:7:5;

[0053] Then add monocyclopentadiene dropwise, the molar ratio of the metal sodium wire to monocyclopentadiene is 1:1.2, and the dropwise addition is completed within 1 hour, and the reaction temperature is controlled to be about 53°C after the dripping to obtain cyclope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com