Flow induction noise isolating and muffling device

A noise reduction device and noise-inducing technology, applied in the direction of measuring ultrasonic/sonic/infrasonic waves, measuring devices, instruments, etc., can solve problems such as interference, frequency conversion, resonance, etc., and achieve the effects of small measurement interference, small size, and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

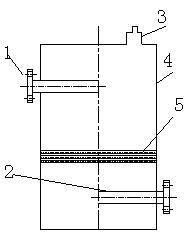

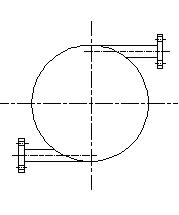

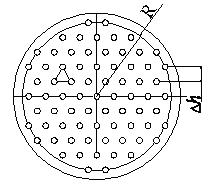

[0013] The test pump (15) runs to pump water out of the pool (13), and then flows into the pool (13) again after passing through the sound insulation and muffler tank (10), the turbine flow meter (11) and the gate valve (12). The air outlet (3) can adjust the height of the air column to avoid strong vibration of the system under a certain gas fraction. The inlet pipe (1) and the outlet pipe (2) are made into movable flange pipes. The holes of the multi-layer board (5) are uniformly distributed in a regular triangle in a circular area with a radius R, and the height h of the triangle is calculated from the number of holes. The holes between the two layers are staggered at an angle of 5-10°. The noise generated by the test pump (15) is separated from the noise generated by the turbine flowmeter (11) and the gate valve (12) by the sound insulation and anechoic tank (10), ensuring that the acoustic signal measured by the hydrophone (9) is the test generated by the pump (15).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com