Backlight module and liquid crystal display device comprising same

A backlight module and backplane technology, which is applied to lighting devices, fixed lighting devices, components of lighting devices, etc., can solve the problems of long heat transfer paths, affecting the service life of components, and the service life of safe liquid crystal panels, avoiding the Stability, improve the stability and service life of components, and reduce the effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

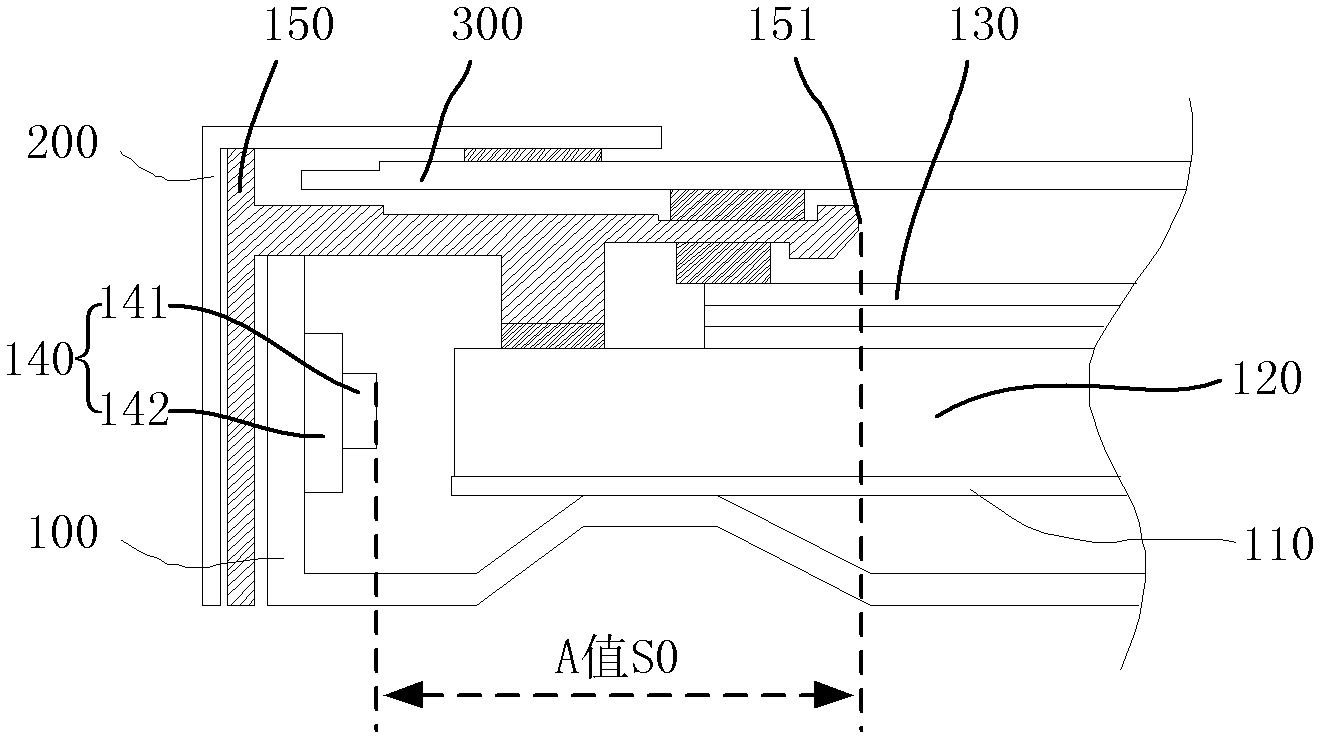

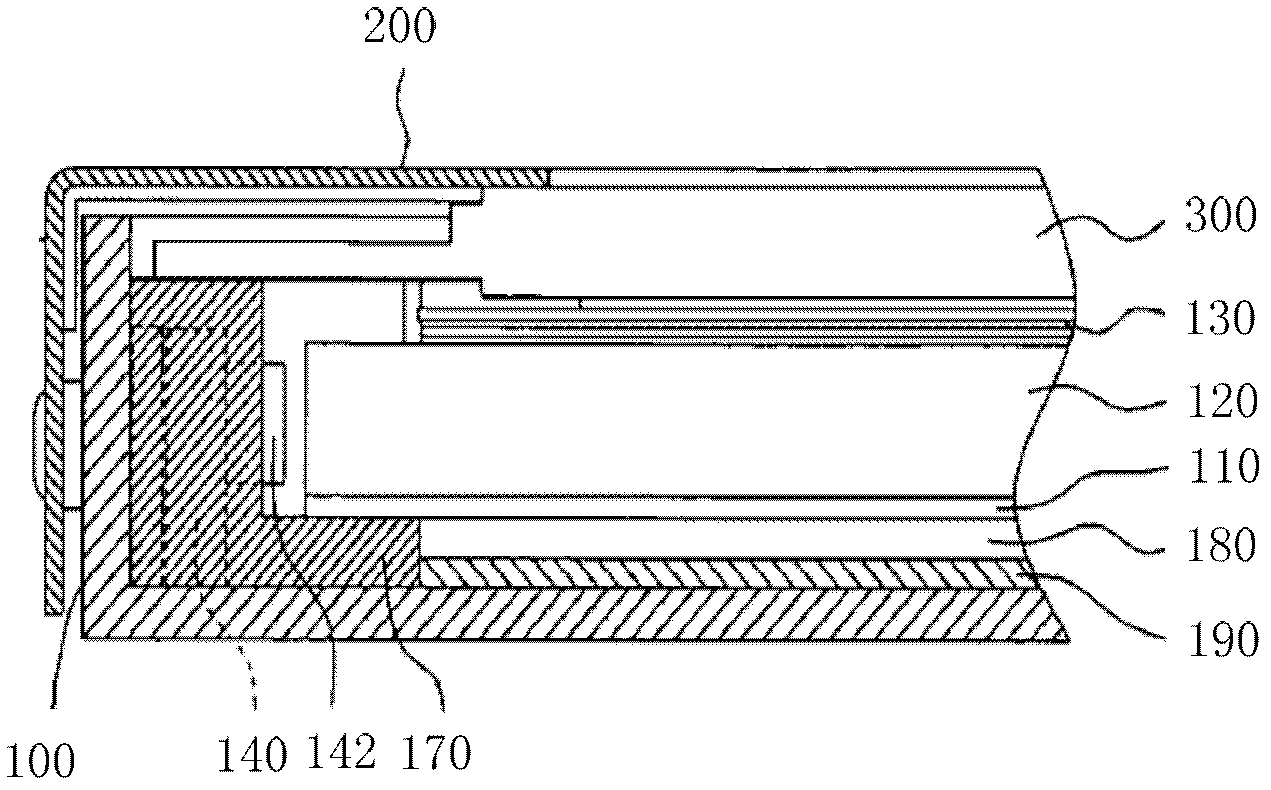

[0034] like image 3 Shown is Embodiment 1 of the present invention. As shown in the figure, the backlight module of the liquid crystal display device includes: a backplane 100, a reflector 110 placed on the backplane 100, placed on the reflector 110 and connected with The light guide plate 120 facing the light bar 140 , the plastic frame 150 and the outer frame 200 arranged outside the back plate 100 and pressed against the light guide plate 120 , the optical film 130 is arranged on the light-emitting surface of the light guide plate 120 , and the liquid crystal panel 300 is composed of Components such as the plastic frame 150 and the outer frame 200 are fixed above the backlight module; wherein, such as Figure 4 As shown, the light bar 140 is arranged on the side wall of the outer frame 200, and the back side of the PCB 142 of the light bar 140 is provided with heat dissipation fins 143, and the heat dissipation fins 143 are in contact with the air outside the outer frame 2...

Embodiment 2

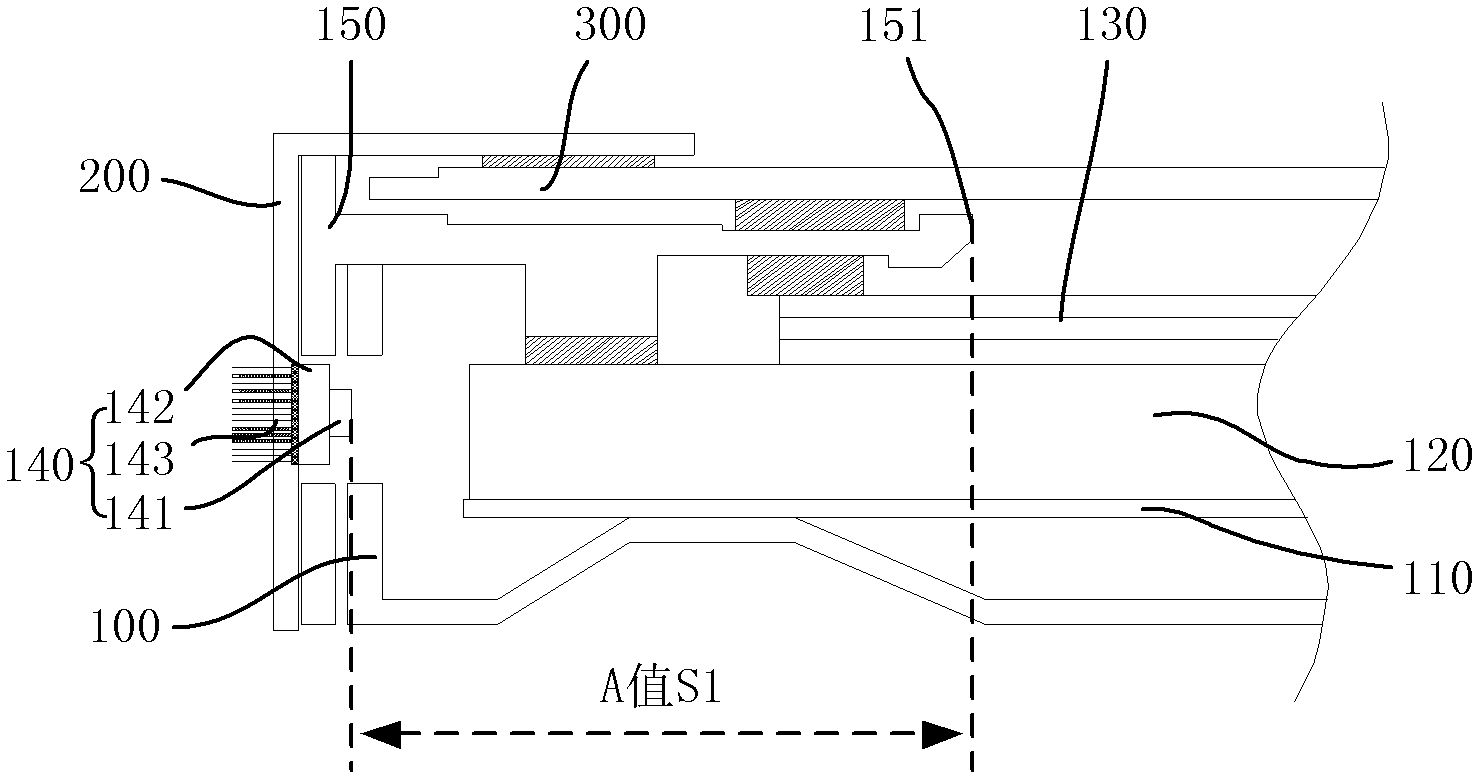

[0039] like Figure 5 Shown is the second embodiment of the present invention, which is different from the first embodiment, such as Image 6 As shown, in this example, the place where the light bar 140 on the outer frame 200 is installed is provided with a boss 210 extending toward the inside of the backlight module. Corresponding to the recess of the backlight module, the purpose of doing so is to facilitate positioning when the backlight module is assembled, and to improve the accuracy and efficiency of assembly. Simultaneously, the thickness setting of the protruding outer frame of the cooling fin 143 is equal to the depth of the boss 210 or less than the depth of the boss 210, so that the cooling fin 143 is completely submerged in the boss 210, ensuring that the cooling fin 143 and the air At the same time, it also prevents the cooling fins 143 from protruding from both sides of the outer frame 200, which will affect the flatness of the outer frame of the liquid crystal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com