Bottom air admission type closed cooling tower

A closed cooling tower and cooling tower technology, applied in water shower coolers, direct contact heat exchangers, heat exchanger types, etc., can solve the problems of small air volume, uneven air distribution, and many fans in the central area. Achieve the effect of saving the cost of structural parts, saving engineering land, and evenly distributing air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Relevant present invention is for reaching above-mentioned purpose of use and effect and the technical means adopted, presents preferred feasible embodiment, and cooperates as shown in the accompanying drawings, detailed description is as follows:

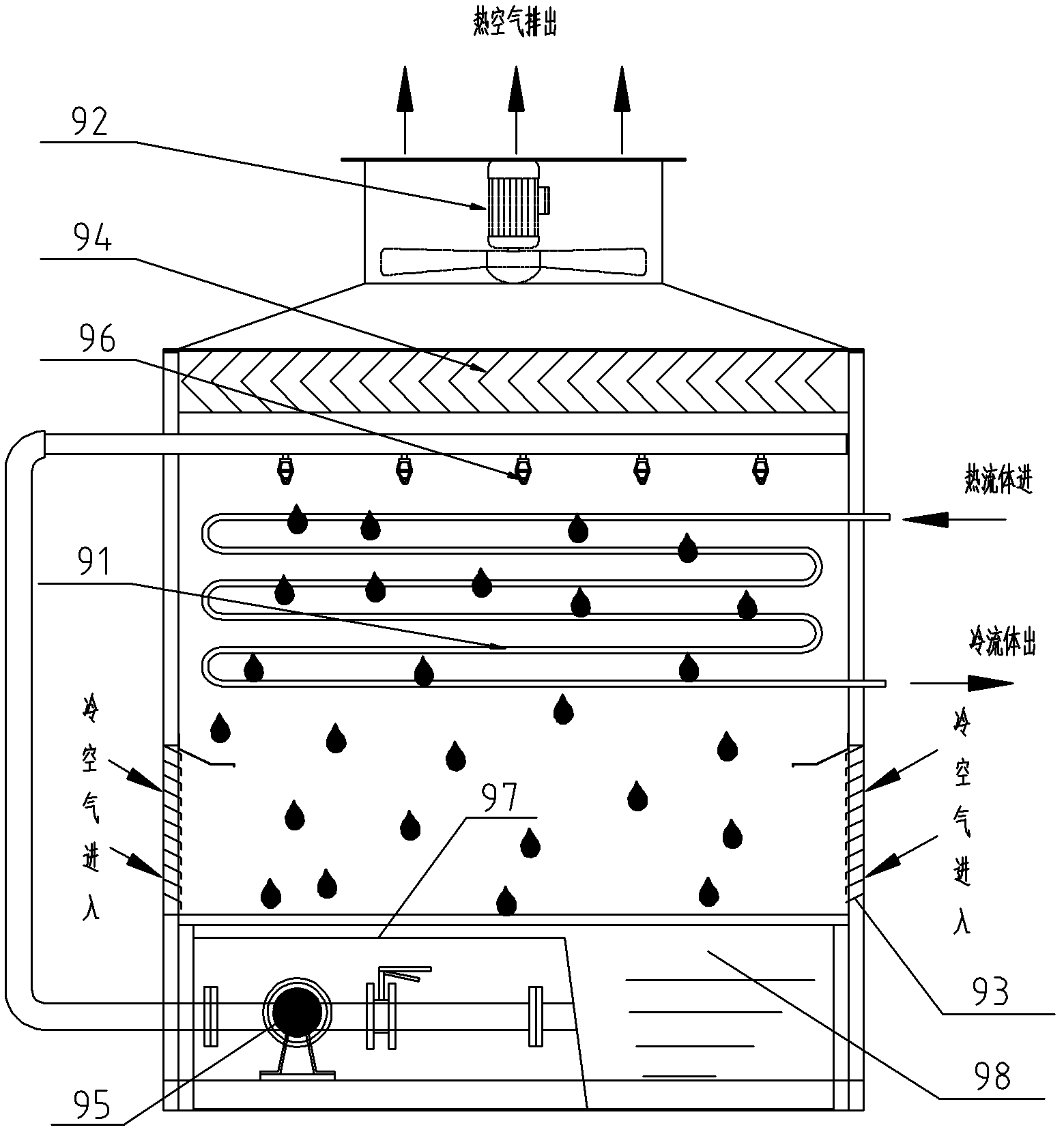

[0034] Such as Figure 4 and Figure 5 Shown, are respectively the sectional view and the side schematic diagram of the closed cooling tower of the present invention bottom air intake; The closed cooling tower of described bottom air intake comprises: blower fan 11, water eliminator 12, spray pipe 13, heat exchange tube Group 14, water guide louvers 15, wind-shielding plate 16, diversion tank 17, water tank 18 and spray pump 19. The fan 11 is arranged on the top of the closed cooling tower shell, the water collector 12 is arranged under the fan 11, the spray pipe 13 is arranged under the water collector 12, and the heat exchange Pipeline 14 is arranged on the below of spray pipe 13, and described water tank 18 is arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com