Irregular cable

A cable and special-shaped technology, applied in the direction of cables, insulated cables, insulated conductors, etc., can solve the problems of unfavorable overhead laying, inconvenient construction, large outer diameter of optical cables, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings; Embodiment 1 to Embodiment 4 are typical embodiments of special-shaped cables of the present invention.

[0023]

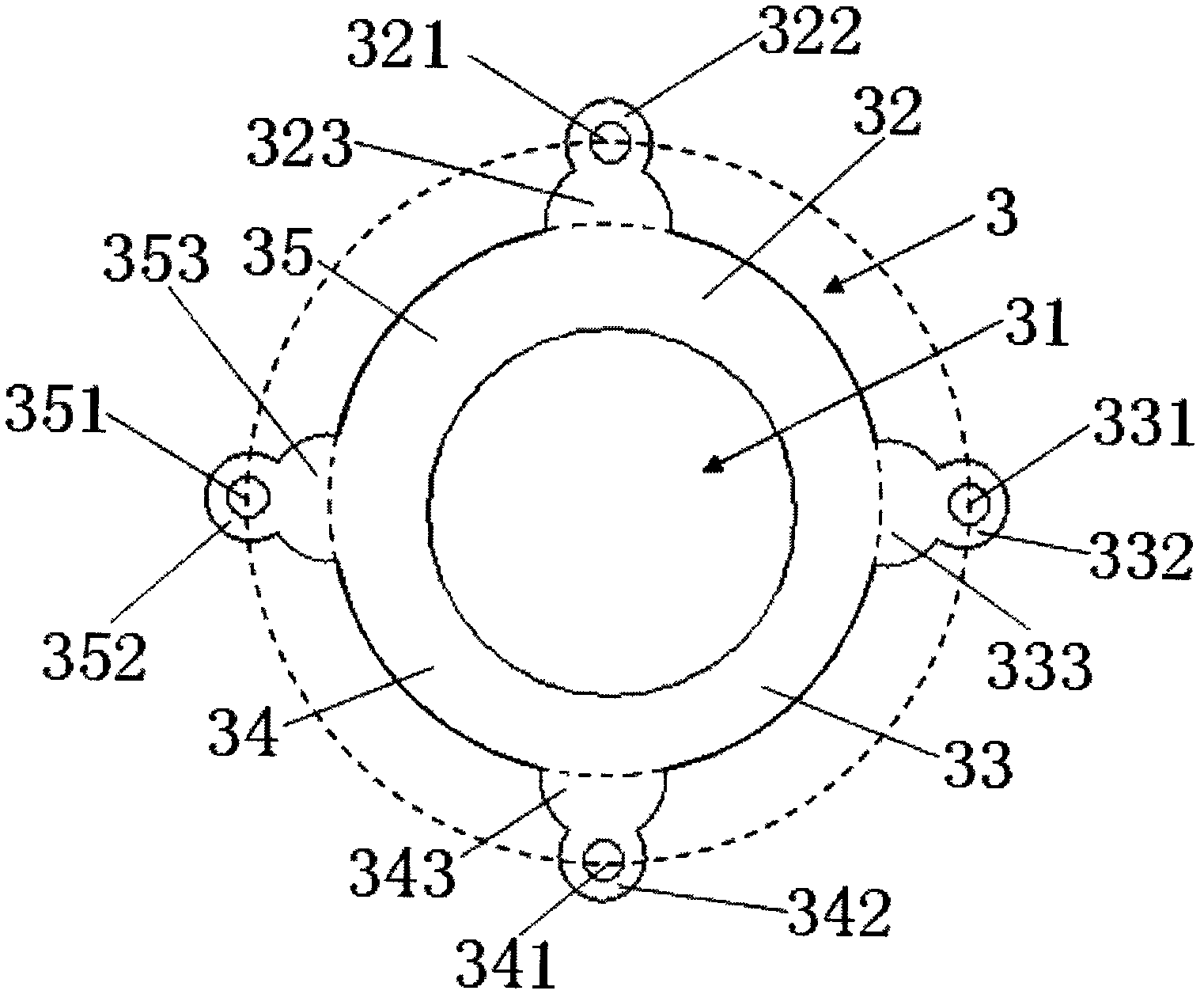

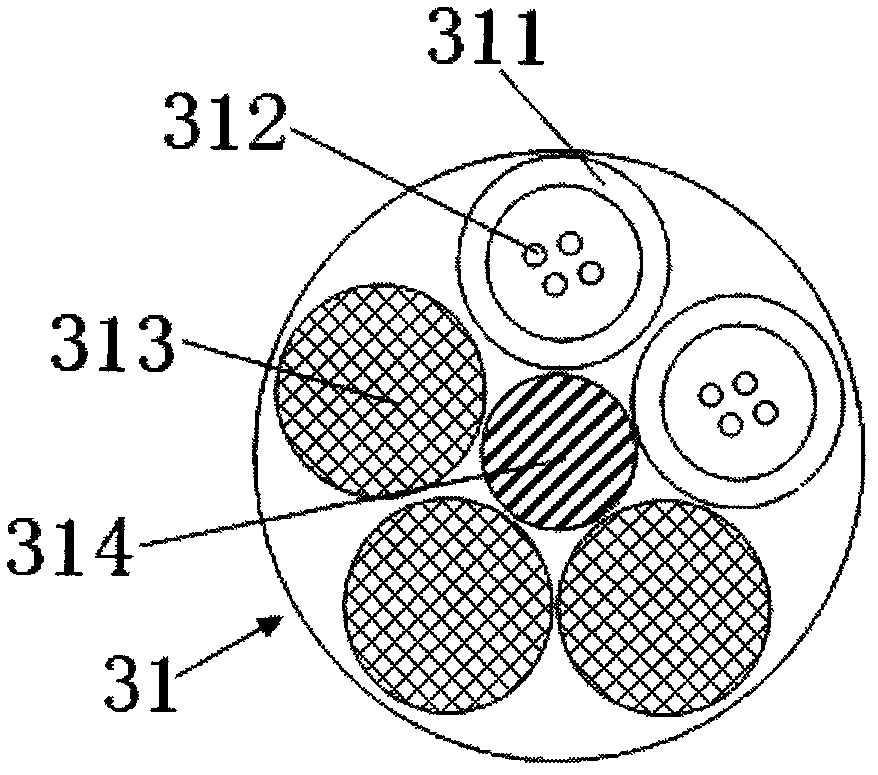

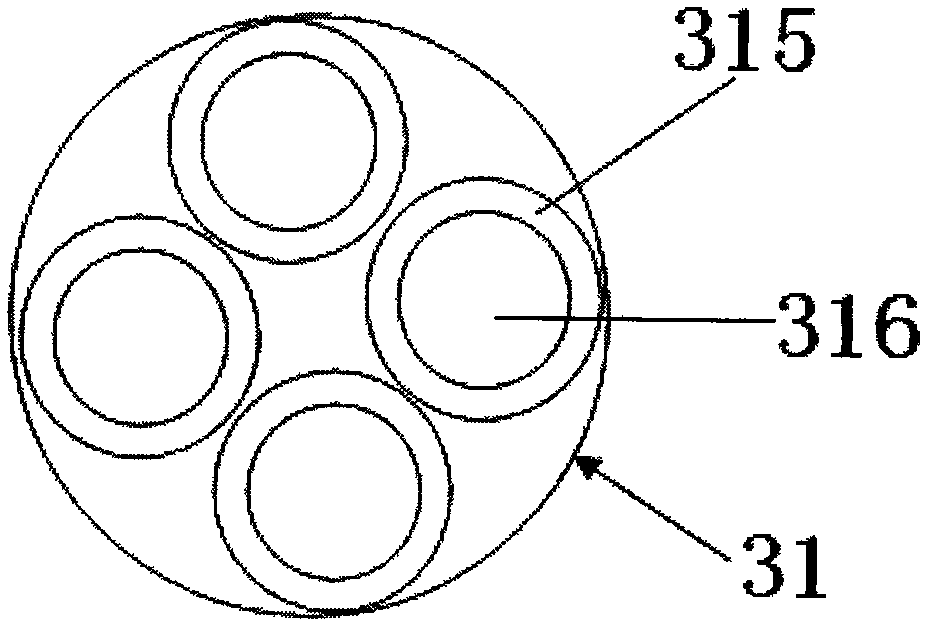

[0024] please see figure 1 and figure 2 , the special-shaped cable 3 is characterized in that it comprises a first special-shaped body, a second special-shaped body, a third special-shaped body, a fourth special-shaped body, a sheath, and a cable core 31; wherein, the first special-shaped body includes: a first reinforced Part 321, the first special-shaped member 322 covering the first reinforcement, the first connecting rib 323 connecting the first special-shaped member and the sheath; the second special-shaped body includes: the second reinforcement 331, covering the second reinforcement The second special-shaped member 332 of the piece, the second connecting rib 333 connecting the second special-shaped member and the sheath; the third speci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com