Pelleter pole lug rubberizing method, rubberizing device and pelleter

A glue-applying device and film-making machine technology, which is applied to battery electrodes, electrical components, circuits, etc., can solve problems such as unstable product quality and glue-sticking, and achieve the effect of overcoming frequent breakdowns and shutdowns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

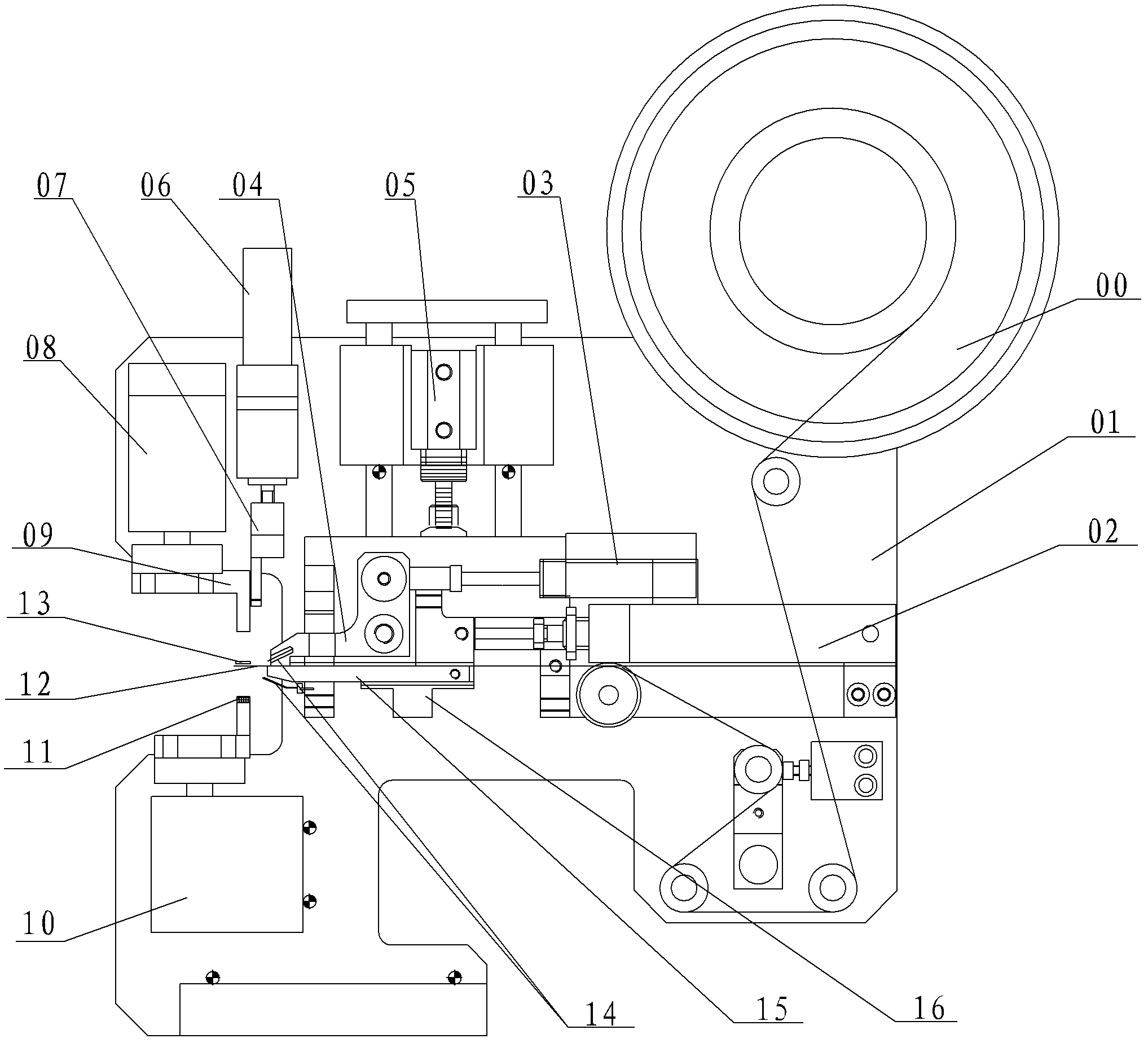

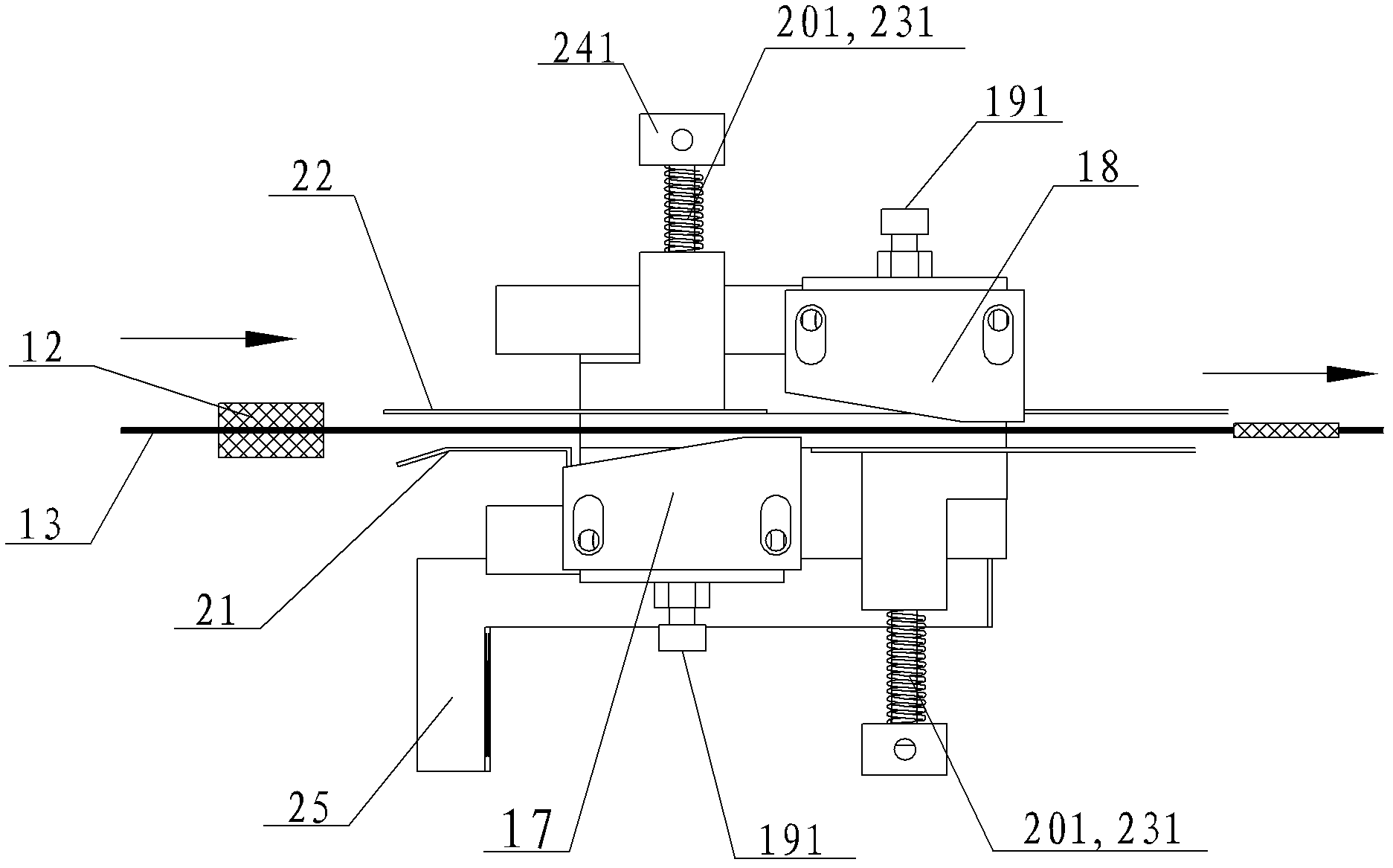

[0030] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

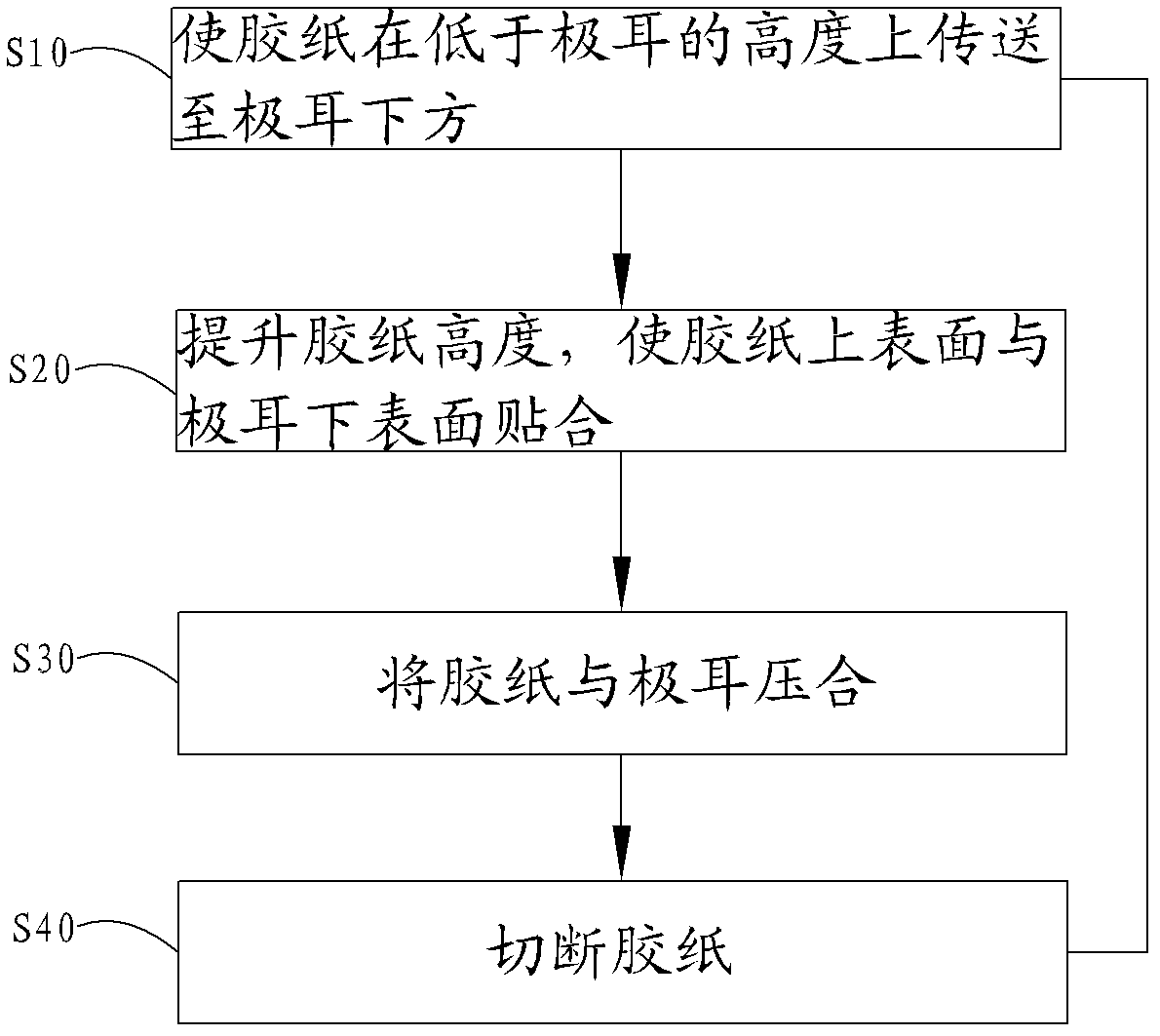

[0031] see figure 1 , the present invention at first proposes a method for pasting tabs of a tablet machine, comprising the steps of:

[0032] S10: conveying the tape to the bottom of the tab at a height lower than the tab, wherein the conveying direction of the tape intersects with the conveying direction of the tab;

[0033] S20: Raise the height of the tape so that the upper surface of the tape fits the lower surface of the tab;

[0034]S30: press the adhesive tape to the tab;

[0035] S40: Cut off the tape, and repeat S10-S40.

[0036] Wherein, the tape conveying direction is preferably perpendicular to the tab conveying direction, which facilitates the arrangement of the tab conveying device, the tape conveying device and the tape ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com