Arc-striking method for plasma torches

A plasma torch and plasma technology, applied in the field of plasma torch arc ignition, can solve problems such as difficulty in arc ignition, achieve the effects of wide application range, prolong service life, increase safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

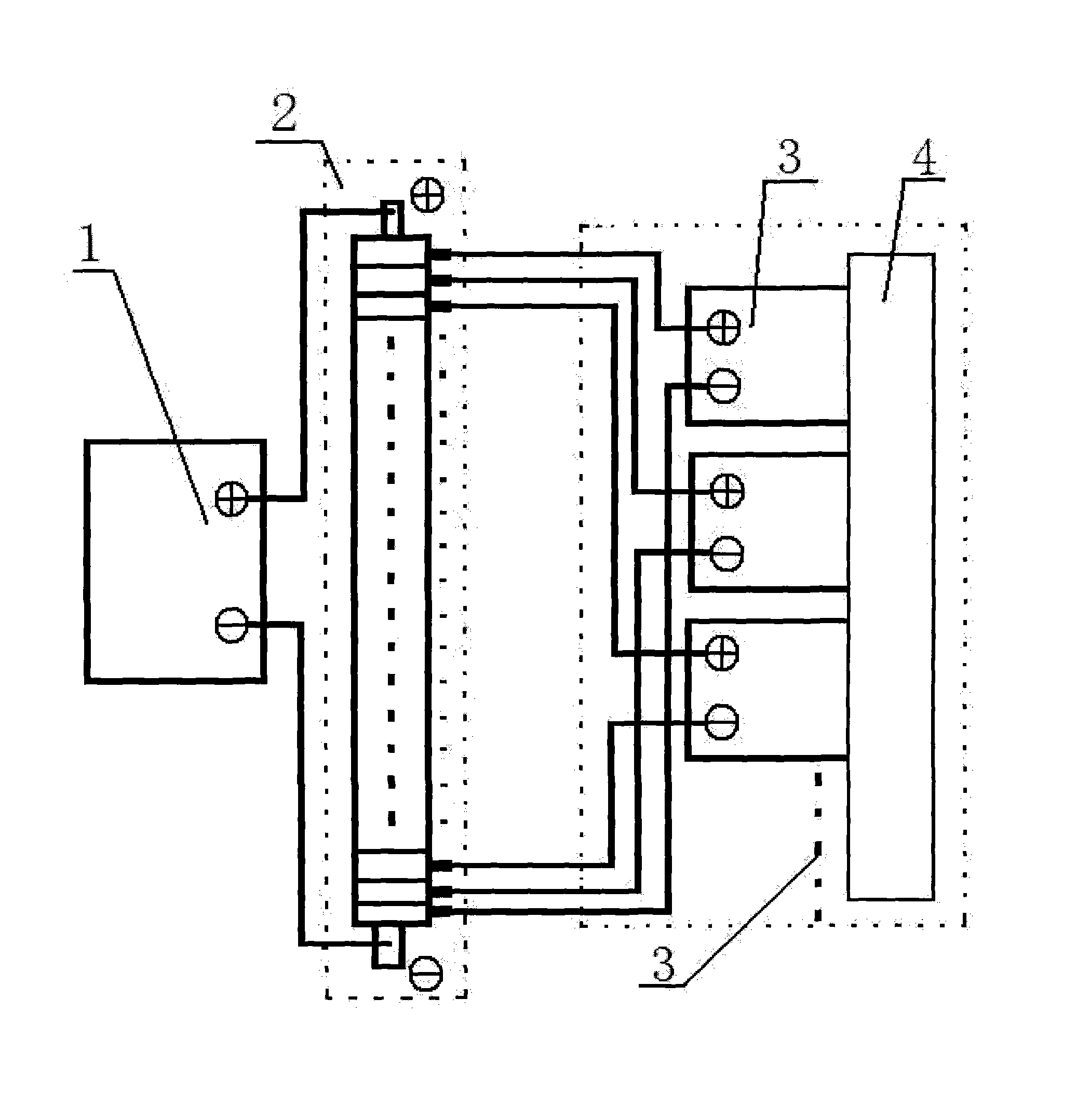

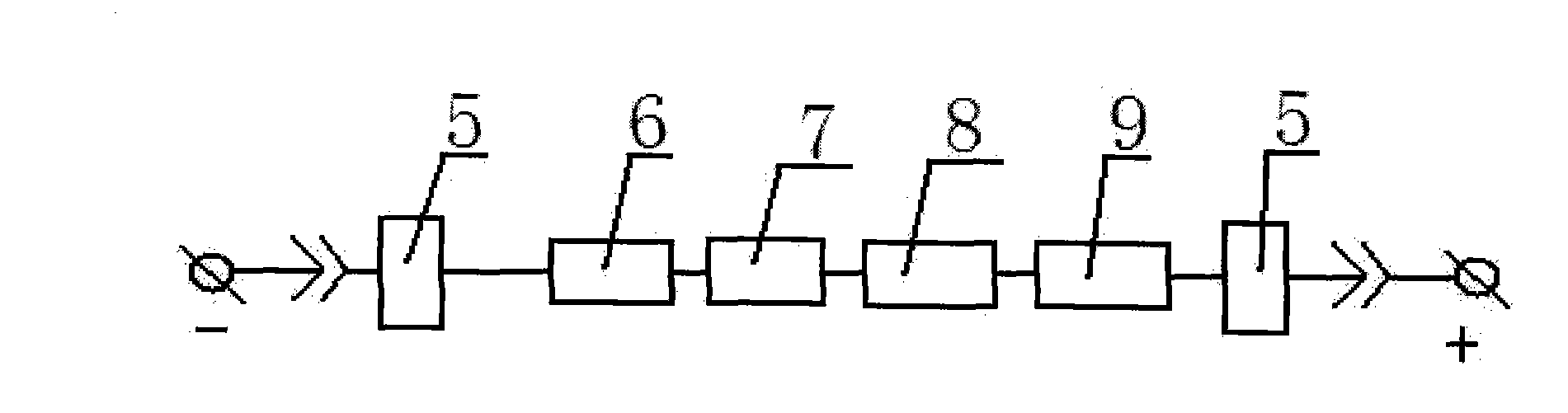

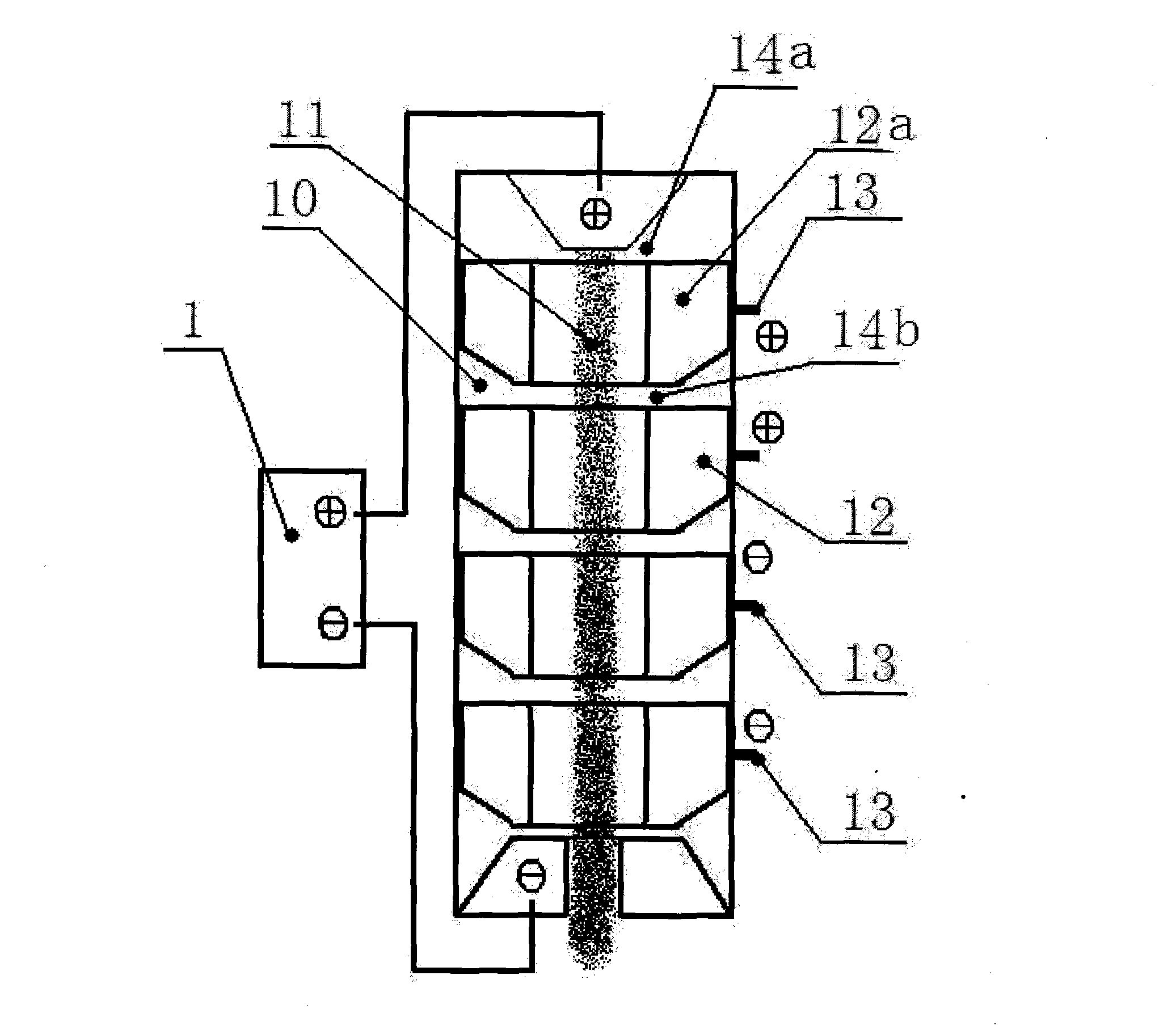

[0021] Such as figure 1 , 2 Shown in and 3; plasma power supply 1 power supply voltage DC6KV; capacitor 9, conjugate coil 8, current limiting resistor 7, diode 6, switching device 5 are connected in series between the positive pole and negative pole of arc striking circuit 3; switching device 5 is controlled by arc striking The control circuit 4 is controlled; the electrode 12 of the plasma torch 2 is provided with an arc starting post 13 for connecting the arc starting circuit 3; the positive pole of the arc starting circuit 3 is connected to the arc starting post 13 near the positive pole of the plasma torch 2, and the negative pole is connected to the plasma torch 2 Negative arc starting pile 13, two arc starting circuits 3 and plasma power supply 1 are connected to plasma torch 2 in parallel; when plasma power supply 1 supplies power to plasma torch 2, the positive pole of plasma torch 2 and the first electrode voltage are 6KV, and the control circuit 4 Start the two arc ...

Embodiment 2

[0023] The difference between embodiment 2 and embodiment 1 is that a 15-way arc ignition circuit is used to strike the V-shaped plasma torch, and the positive and negative electrodes of the torch simultaneously penetrate into the middle electrode of the plasma torch 2 in sequence.

Embodiment 3

[0024] The difference between Embodiment 3 and Embodiments 1 and 2 is that only a capacitor 9 and a switching device 5 are connected in series between the positive pole and the negative pole of the arc strike circuit 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com