LED (light emitting diode) chip mounter

A technology of LED placement machine and placement device, which is applied in the direction of assembling printed circuits with electrical components, can solve the problems of low work efficiency and inability to meet large-scale production, and achieve the effect of improving placement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

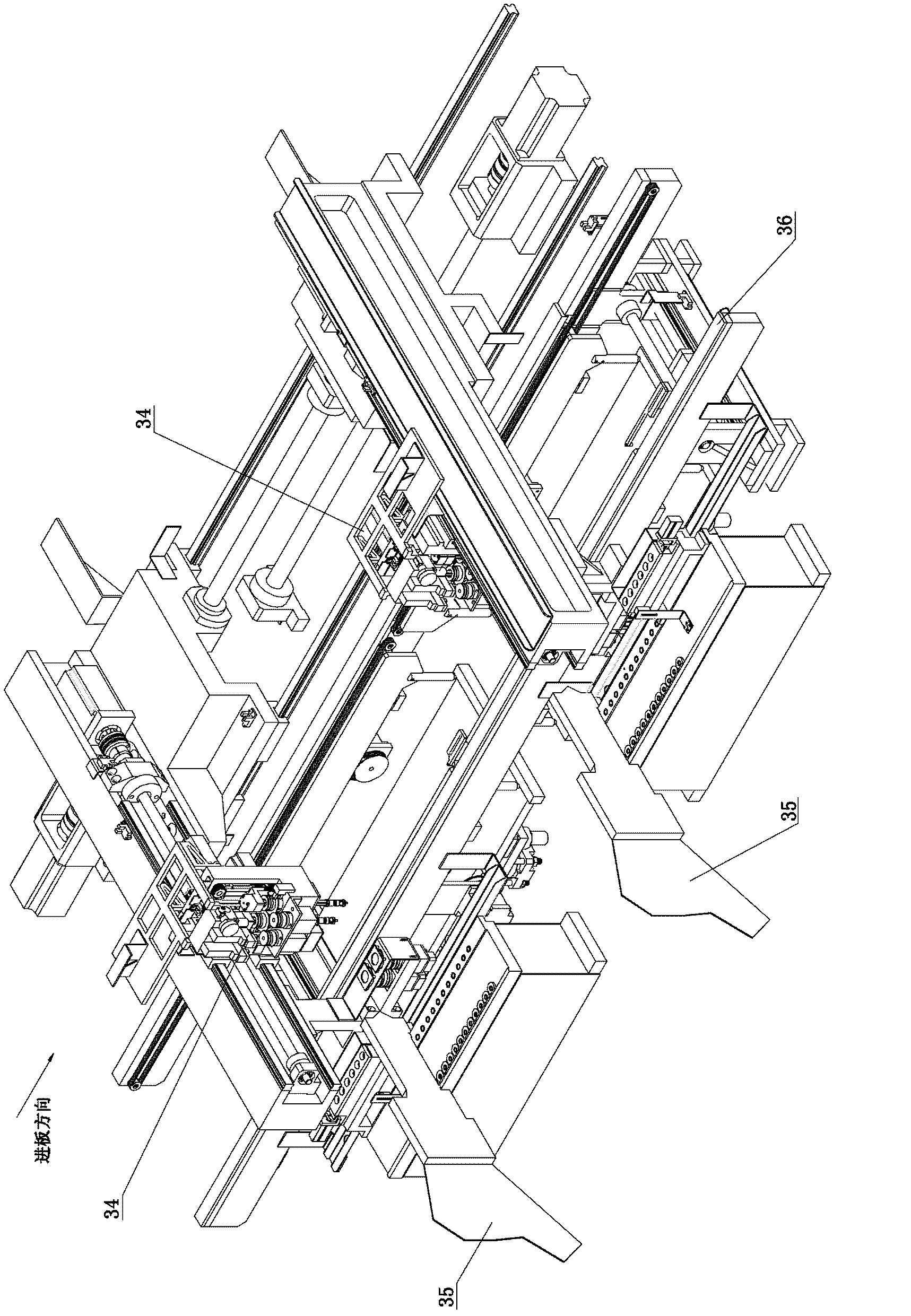

[0021] Such as figure 1 As shown, the LED placement machine of the present invention includes two sets of single-arm multi-head placement devices 34 , two sets of feeding devices 35 and two-stage board feeding devices 36 .

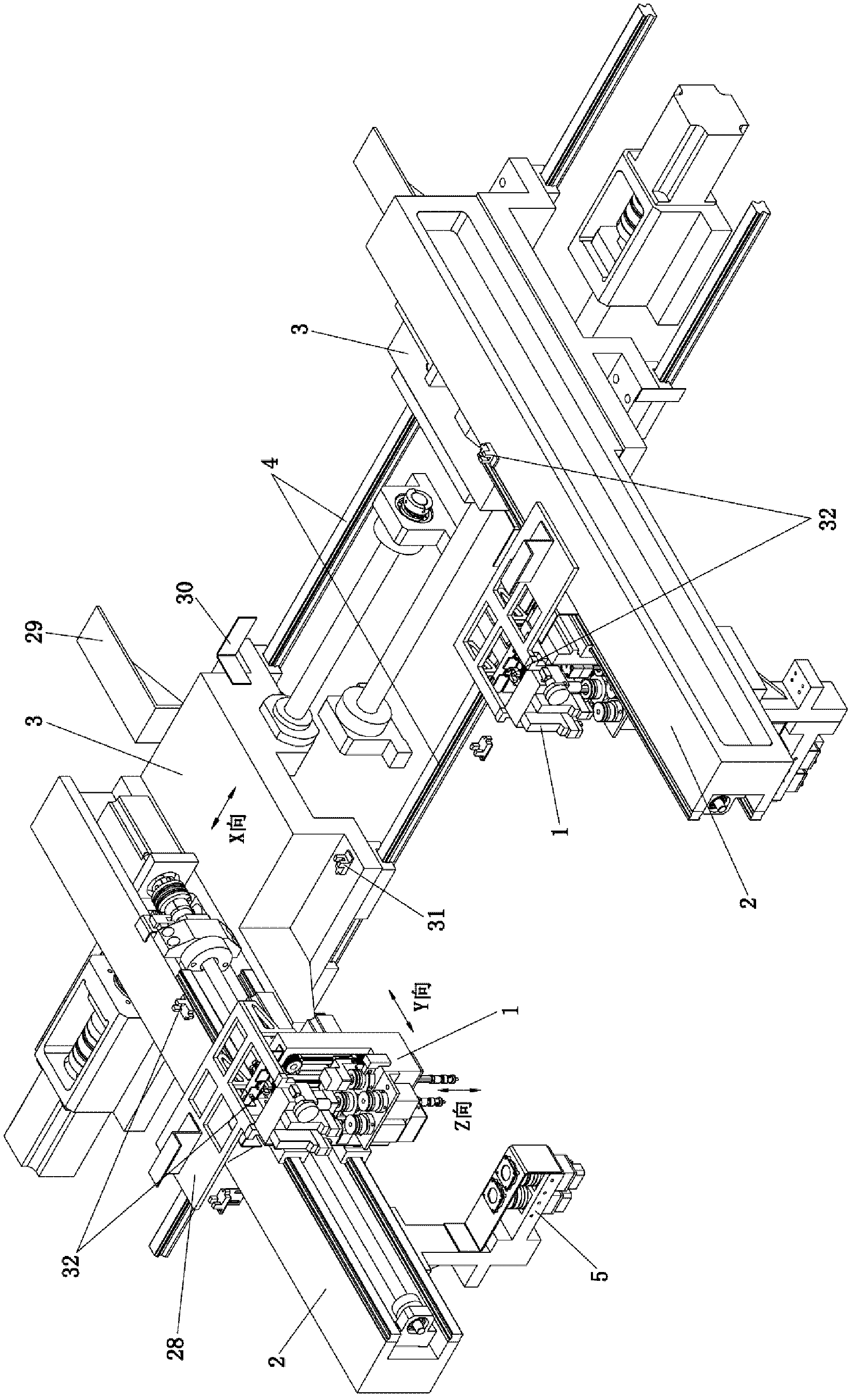

[0022] Such as figure 2 As shown, two sets of single-arm multi-head placement devices 34 are mainly composed of two sets of placement head assemblies 1, two sets of moving arm mechanisms 2, two sets of translation seat assemblies 3, two X-guiding guide rails 4 and two sets of suction head flying CCD cameras. Device 5 is composed. A set of mounting head assembly, a set of moving arm mechanism and a set of translation seat assembly are assembled into a single-arm multi-head placement device.

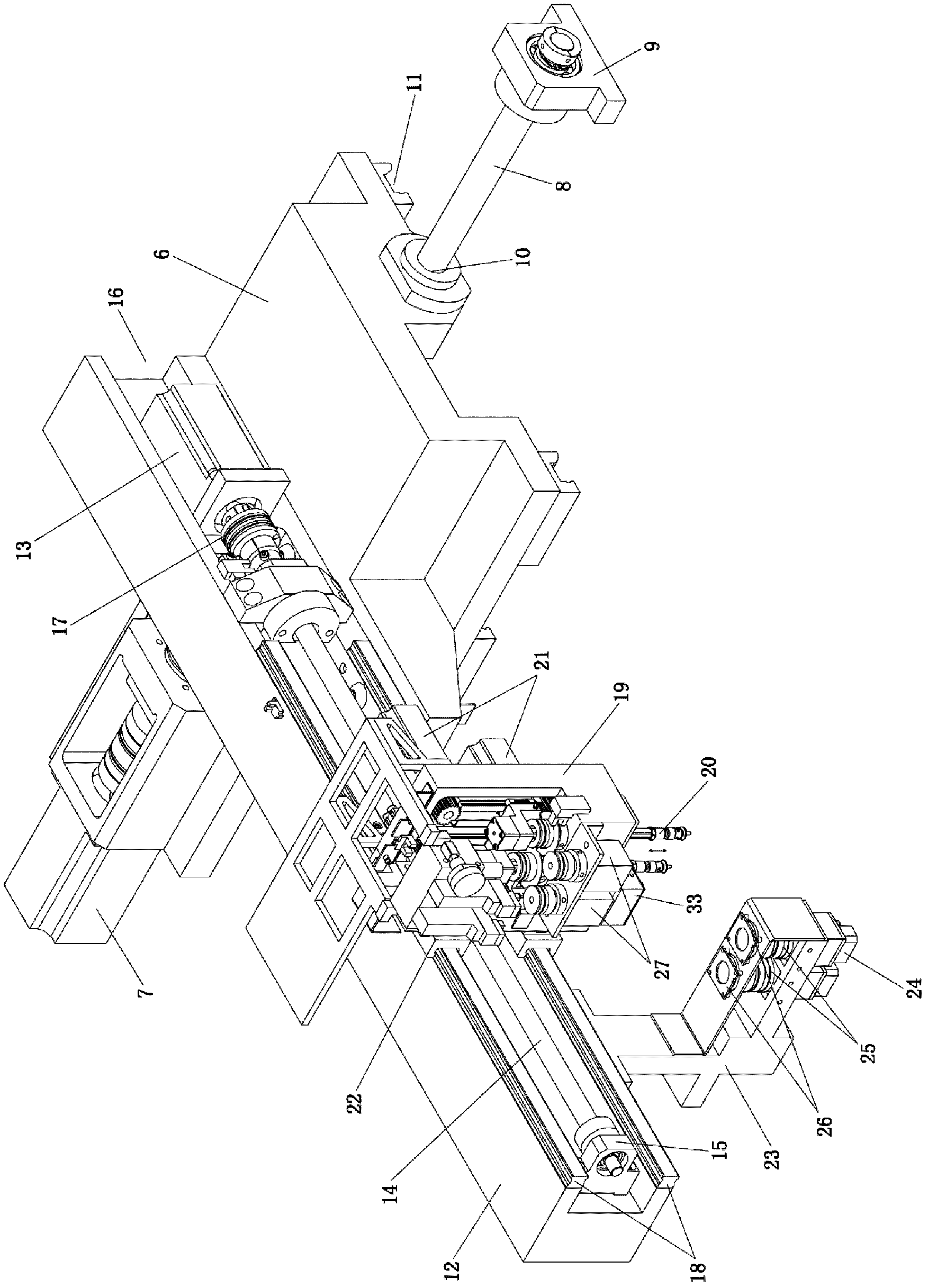

[0023] Such as image 3 As shown, the translation seat assembly 3 is composed of a support 6, an X-direction servo motor 7, an X-direction screw 8 and a bearing seat 9, and is used for installing the moving arm mechanism. A screw nut 10 is installed in the middle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com