Controller shell for electric vehicle

A technology for electric vehicle controllers and casings, which is applied in the direction of metal casings, cooling/ventilation/heating transformation, etc., and can solve the problem of poor performance of controller circuit board components, damage of controller circuit board components, failure to timely and fully problems such as heat dissipation, to achieve the effect of long-term stable work, good heat dissipation, and strong online monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

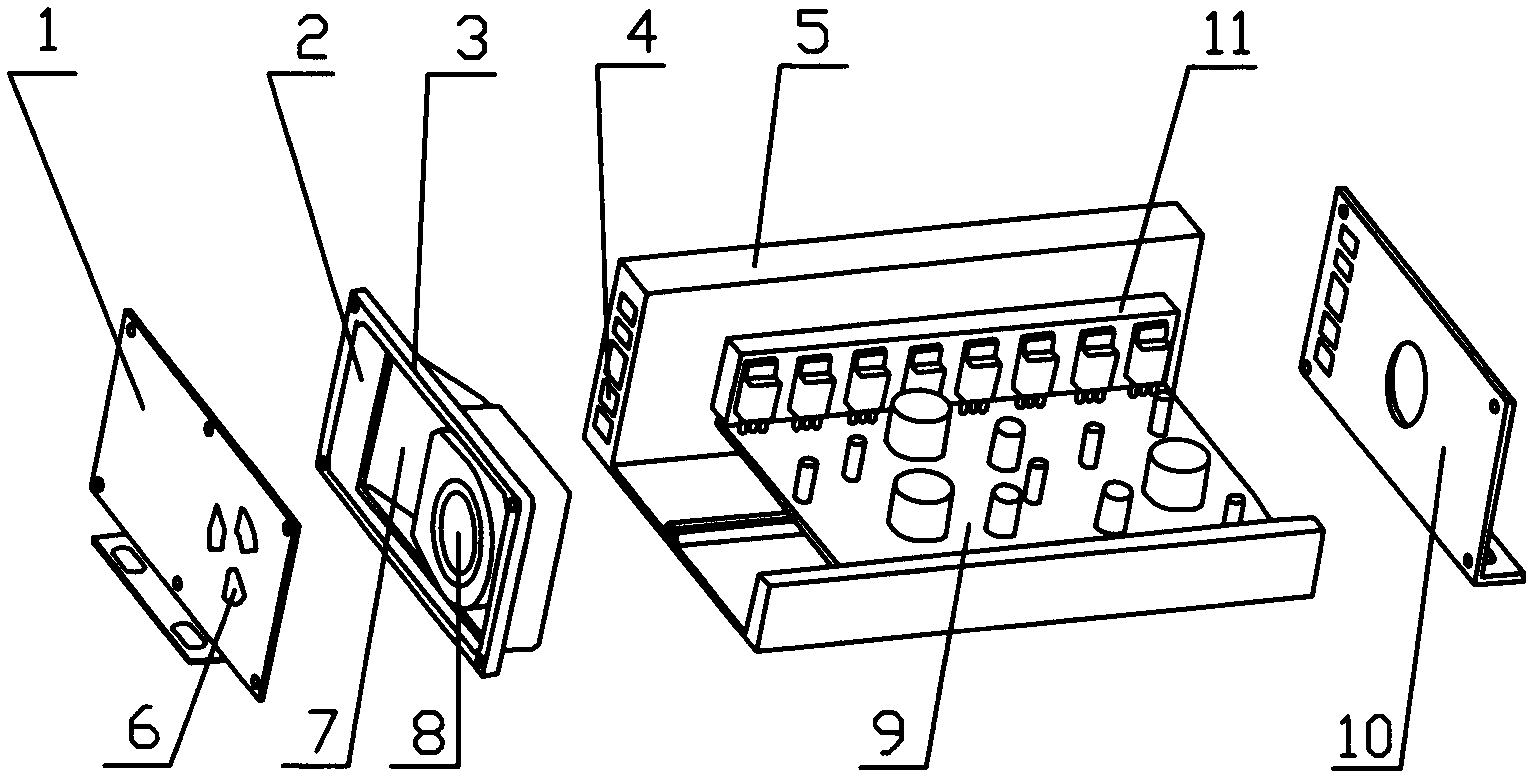

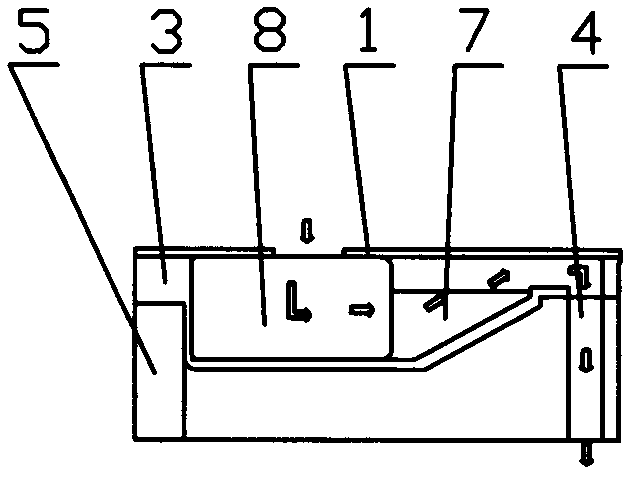

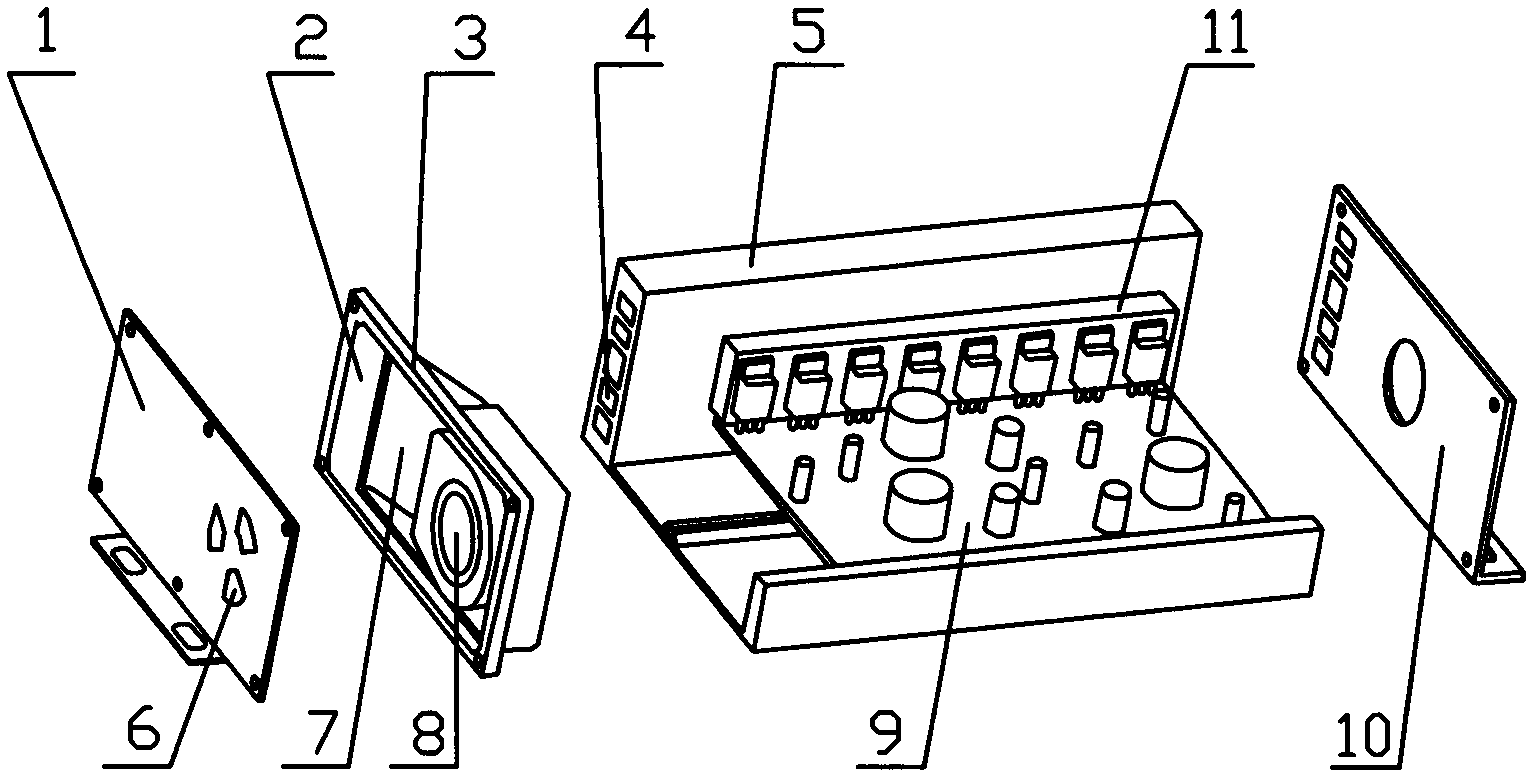

[0018] Such as figure 1 , figure 2 Shown, a kind of electric vehicle controller shell, its main body is aluminum shell 5, and aluminum shell 5 is the cylinder body that cross section is square, and the two ends of aluminum shell 5 are respectively made of front fender 10, rear fender The board 1 is closed, the rear baffle 1 is equipped with a fan 8, the circuit board 9 is fixedly connected to the inner wall of the aluminum housing 5, and a heat dissipation air duct 4 is opened on the side wall of the aluminum housing 5 along the length direction of the aluminum housing. , the heat dissipation air duct 4 is five channels arranged vertically, each channel is horizontal and parallel to each other, the heat dissipation air duct 4 runs through the side wall of the aluminum shell; There is a groove on the inner surface, and the heat dissipation aluminum strip 11 is fixed in the groove. The CMOS power tube is connected to the heat dissipation aluminum bar 11 . An air flow steerin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com