Tea making device with heat radiator

A technology for tea-making utensils and radiators, which is applied in household utensils, kitchen utensils, beverage preparation devices, etc. It can solve the problems of easy dust accumulation, inconvenient use, and unadjustable water temperature, and achieve accurate heat dissipation, convenient use, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

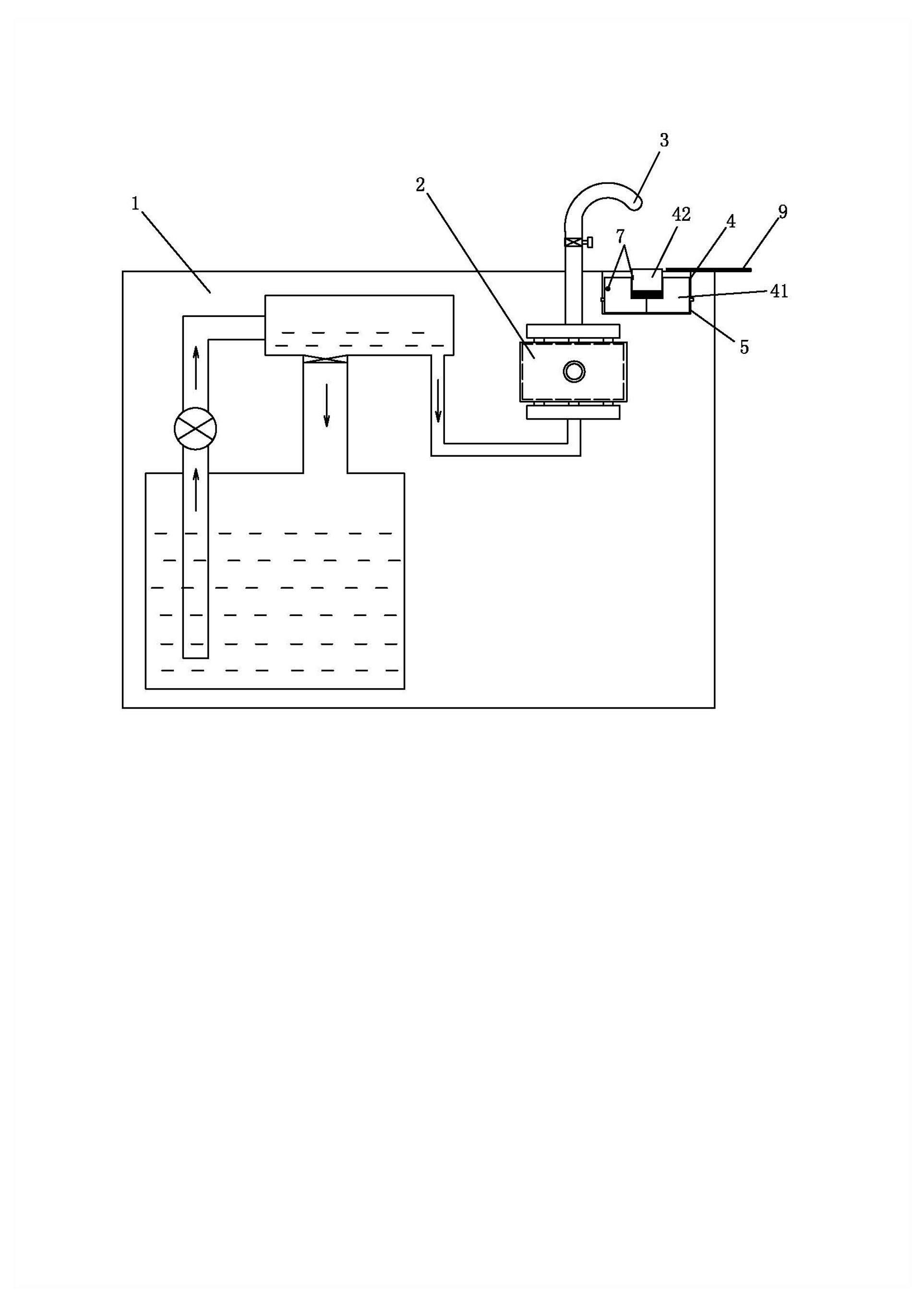

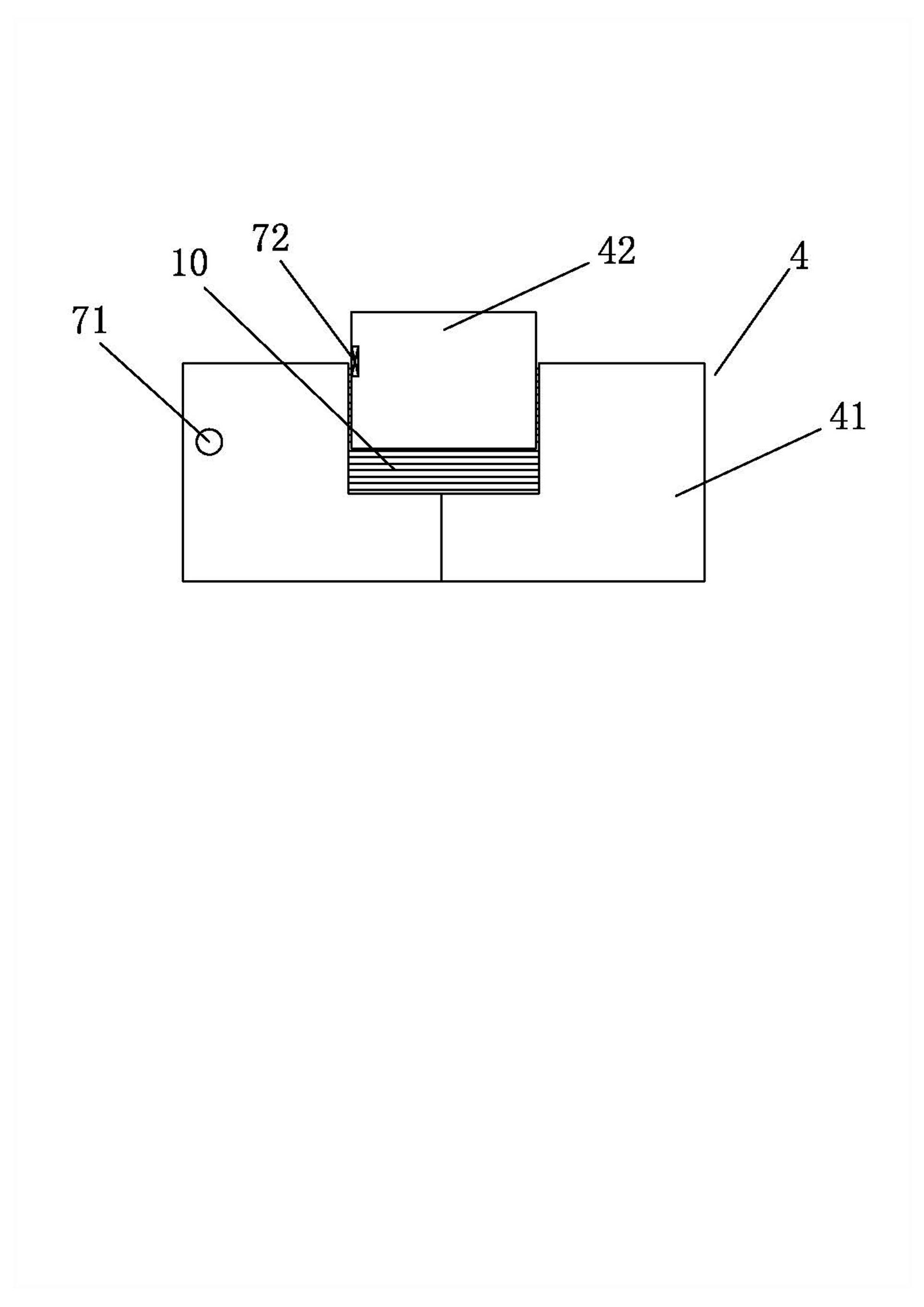

[0028] Embodiment one: if figure 1 with figure 2 As shown, a tea-making appliance with a radiator includes a tea-making base 1, an electric heater 2, and a spout 3. It is characterized in that a metal radiator 4 is arranged on the tea-making base 1, and the metal dissipates heat. The device 4 is composed of at least two metal shells, one metal shell is used as a heat sink vessel 41, and the other metal shell is used as a drinking water loading vessel 42. The heat dissipation vessel 41 is in surface contact; the tea making seat body 1 is provided with an installation groove 5, and the heat dissipation vessel 41 is connected to the installation groove 5 by buckling, fixing or bonding.

[0029] There is a recess 6 on the surface of the heat dissipation vessel 41, and the drinking water container 42 is embedded in the recess 6 and is in close contact with the wall surface of the recess 6; in the figure, the heat dissipation vessel 41 can be spliced by two metal shells, which i...

Embodiment 2

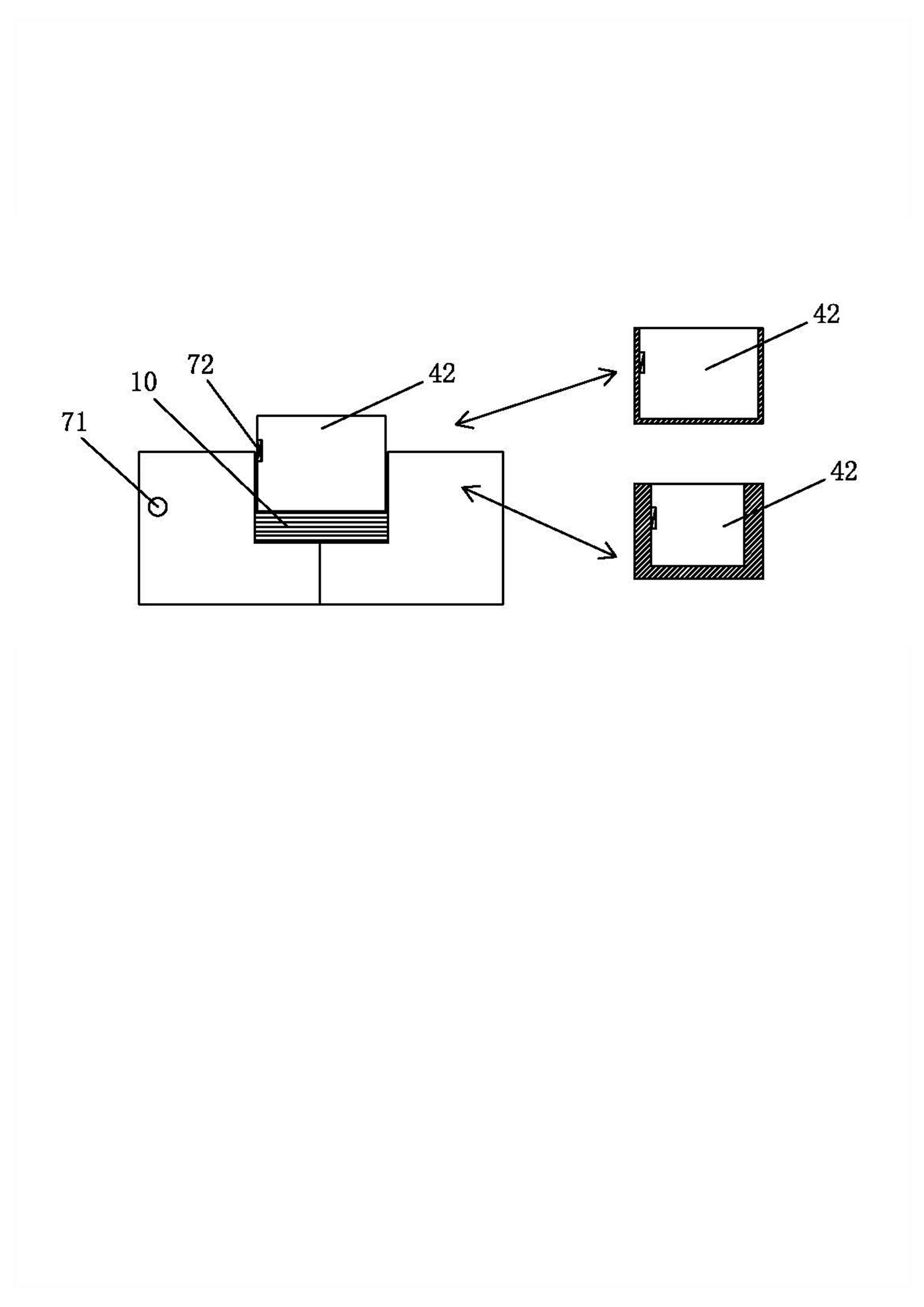

[0034] Embodiment two: if image 3As shown, its implementation mode is similar to that of Example 1, the difference is only: it does not need a threaded surface connection structure, as long as a plurality of metal shells are arranged on the metal radiator as independent drinking water loading vessels 42 , people can use multiple metal shells with different thicknesses (or different sizes) (namely: drinking water loading vessel 42) to meet different heat dissipation temperature requirements, and choose a suitable metal shell to cooperate with the heat dissipation vessel 41 to achieve hot water temperature. Adjustment function.

Embodiment 3

[0035] Embodiment three: as Figure 4 As shown, its implementation mode is similar to that of Embodiment 2, and the difference is only: it does not need a threaded surface connection structure, as long as a plurality of recesses 6 are provided on the surface of the cooling vessel 41, and a plurality of drinking water loading vessels 42 are matched, Each drinking water container 42 is embedded in the corresponding recess 6 and is in close contact with the wall of the recess 6; this design is to meet the requirements of various heat dissipation and cooling, that is, people pass through drinking water of different sizes and thicknesses. The loading vessel 42 is placed in the recess 6 corresponding in size, so as to meet the different needs of various tea making temperatures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com