Lime cooling equipment of sleeve kiln

A technology of cooling equipment and sleeve kiln, which is applied in the field of lime cooling equipment, can solve the problems of affecting lime cooling effect, lime product quality, uneven distribution of cooling air, easy segregation of cooling air, etc., so as to avoid air segregation, simple structure and low cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

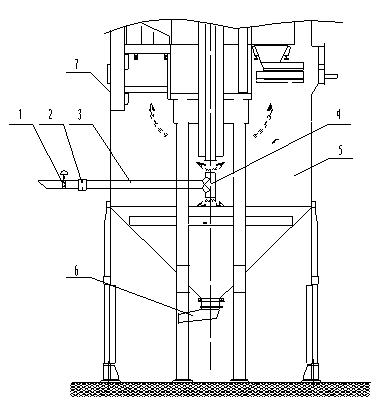

[0015] The sleeve kiln lime cooling equipment of the present invention, as figure 1 As shown, it includes a ventilation pipe 3 and a draft pipe 4, and a flow meter 2 and a regulating valve 1 are installed on the ventilation pipe. The sleeve kiln is equipped with a preheating zone, a calcination zone and a cooling zone. The ventilation pipe is inserted into the lime storage bin 5 at the lower part of the kiln body from the side wall of the kiln body 7, and the ventilation pipe is welded to the draft pipe. The guide pipe is a straight pipe structure with upper and lower openings, and the guide pipe is installed in the center of the kiln body. The ventilation pipe 3 and the draft pipe 4 are made of carbon steel.

[0016] The present invention utilizes the negative pressure in the kiln body to suck cold air into the cooling zone to cool the lime. Since the guide pipe is located in the center of the kiln body, the upper and lower open structures, such as figure 1 As shown, the c...

Embodiment 2

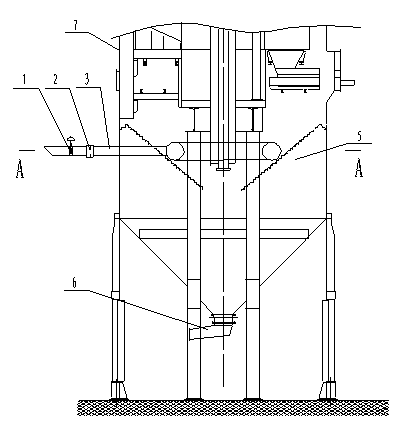

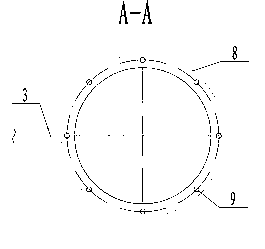

[0018] Another embodiment of the present invention is as figure 2 As shown, the distributor is an annular distribution pipe 8, and the material of the annular distribution pipe is stainless steel. The annular distribution pipe is welded to the ventilation pipe 3. like image 3 The upper and lower sides of the annular distribution pipe shown are respectively provided with 8 air outlet holes 9, and the diameter of the air outlet holes is 50mm. The air outlet holes are evenly distributed on the annular distribution pipe, and the cooling air enters the cooling zone through the air outlet holes of the annular distribution pipe to evenly distribute the cooling lime, without segregation, and the cooling effect is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com